Oil Diamond Drill Bit Field Application Review

Oil Diamond Drill Bit field applications represent a critical advancement in modern drilling operations, particularly within oil and gas exploration, where performance and reliability determine operational success. These specialized drilling tools combine industrial-grade diamonds with advanced matrix materials to deliver superior cutting efficiency and extended operational life in challenging geological formations. Throughout the petroleum industry, oil diamond drill bits have transformed drilling operations by providing enhanced penetration rates, reduced downtime, and improved cost-effectiveness compared to conventional drilling solutions. The technology addresses complex drilling challenges in medium- to hard-rock formations, making them indispensable for oil service companies seeking optimal drilling performance.

Understanding Oil Diamond Drill Bits and Their Field Applications

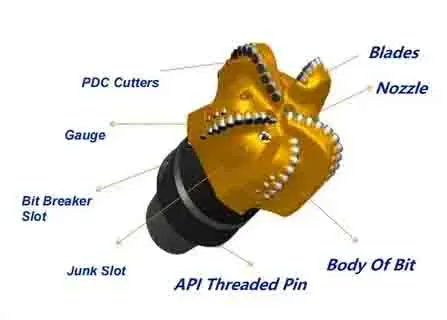

Oil diamond drill bits are high-tech engineering solutions made just for tough conditions. Industrial diamonds are embedded in a carefully formed metal core in the composite structure. This makes cutting surfaces that stay sharp even in harsh working conditions. This way of designing bits cuts more efficiently than older ones, especially when drilling through hard rock types that are common in oil research projects.

Embedded diamond technology has a number of practical benefits that have a direct effect on how well drilling works. The advanced diamond crystals keep cutting well even after long drilling sessions, and the tungsten carbide core makes sure the structure stays strong under high pressure. Specialized steel alloys built into the bit body make it more resistant to impact. This means that these tools can be used for tough drilling jobs in a wide range of natural formations.

Modern drilling processes gain from the fact that oil diamond drill bits can be used in a lot of different industries. In oil and gas research and production, where steady performance through difficult formations is key to project success, these high-tech drilling tools are the best. These bits are used in geothermal drilling because they can keep cutting well in hot environments, and they are also used in coal bed methane extraction for their ability to cut precisely.

Mineral processing plants that use hard rock are another important area where oil diamond drill bits work really well. Teams that drill water wells like these tools because they are reliable and don't cost a lot of money, especially when drilling through medium-hardness rocks. Geological core sampling projects benefit from the exact cutting action that keeps the purity of the samples, and horizontal directional drilling operations depend on their long life and reliable performance.

Comparison and Performance Insights: Oil Diamond Drill Bits vs. Alternatives

A thorough study of their performance shows that oil diamond drill bits are much better than PDC and tungsten carbide options. Durability tests show that the equipment will last longer, and diamond-coated cutting surfaces will continue to work well after many drilling rounds. Studies of penetration rates consistently show performance benefits, especially in medium-hard rock types like shale, limestone, sandstone, and gypsum deposits.

Maintenance needs are another important thing for buying workers to compare when they are looking at drilling technologies. Oil diamond drill bits don't need to be replaced as often as other types, which cuts down on working downtime and the costs that come with it. Diamond cutting elements are self-sharpening, which means that their performance stays the same over the life of the bit. This means that drilling results can be planned for and costs can be kept under control.

Oil diamond drill bits have a higher starting cost than basic alternatives, but investment research shows that they are worth it in the long run. The total cost of ownership goes down because bits last longer, need to be replaced less often, and dig more efficiently, according to operational statistics. Business-to-business buying managers find that bulk shopping methods make things even more cost-effective, especially for large-scale drilling jobs that need tools to work consistently.

The operational factors of speed between 80 and 300 R/min, drilling pressure between 10 and 100 KN, and flow rates between 20 and 35 LPS allow for operating freedom that can adapt to different formation characteristics. This adaptability lets the best drilling settings be used for each type of rock, which improves both efficiency and cost-effectiveness in a wide range of drilling situations.

Best Practices and Maintenance Tips for Oil Diamond Drill Bits

To get the most use out of oil diamond drill bits, they need to be maintained in a way that keeps them working well and keeps their structure intact. The state of the diamond cutting elements, the wear patterns on the matrix, and the general shape of the bit should all be checked on a regular basis. When you clean properly, you get rid of formation debris and stop buildup that could hurt hydraulic flow and cooling.

Storage and handling rules are very important for keeping bits in good shape between drilling jobs. Cutting elements don't rust or get damaged when they're stored in a controlled environment, and the precision-engineered cutting surfaces are kept safe by following the right handling methods. During the bit's working life, these maintenance techniques have a direct effect on how well it works and how much it costs.

One important thing to do to get the most out of oil diamond drill bits is to optimize the drilling parameters. By changing the torque and flow rate based on the properties of the formation, the best cutting action is achieved while premature wear is avoided. The improved hydraulics design in these bits makes hole cleaning more effective, lowers the risk of bit balling, and keeps drilling performance uniform.

To fix common practical problems, you need to know how formation features and drilling parameter relationships work together. Bit wear patterns give useful troubleshooting information for improving drilling methods and keeping performance from dropping. By using systematic analysis to find and fix problems like sudden vibrations, lower penetration rates, or strange wear patterns, you can keep operations running smoothly and add more life to bits.

Procurement Guide: Buying Oil Diamond Drill Bits for B2B Clients

When buying oil diamond drill bits, procurement professionals have to look at sellers based on their manufacturing skills, quality certifications, and expert support services. OEM capabilities give you access to unique solutions made to fit your drilling needs, and valid certifications show that you're following industry standards and quality requirements. Regional manufacturing advantages help the supply chain and make expert support easier to get.

Shaanxi Hainaisen Petroleum Technology Co., Ltd. has all the skills needed to provide a stable bit supply. The company has been around since 2013 and has a 3,500 m building with modern production workshops and high-tech processing tools like 5-axis machining centers, CNC machine tools, and welding production lines. The specialized research and development team can make unique bits that meet a wide range of structural needs for a variety of drilling tasks.

Strategic methods for buying things stress the benefits of getting them in bulk, which lowers unit costs and makes sure there is enough stock for long-term digging operations. Clear price talks should include savings for buying in bulk, shipping times, and warranty terms that protect the value of the investment. With customization choices, procurement teams can choose bit designs that work best in certain rock formations and drilling situations.

The customization service method takes into account that each drilling project has its own problems that need custom answers. Professional technical teams work with clients to create and produce bits that are best for certain rock types and practical needs. This ability to be customized ensures the best performance while keeping costs low in a wide range of drilling uses.

Future Trends and Innovations in Oil Diamond Drill Bit Technology

As technology keeps getting better, new materials and ways of making things are changing how well oil diamond drill bits work. Eco-friendly material development lessens the damage to the environment while keeping or even improving the performance of drills. Cutting elements with better properties are made using advanced diamond synthesis methods that are meant for tough drilling jobs.

Digital integration is a new trend that makes tracking and improving drilling performance easier. Smart drilling technologies give you real-time information about how well the drilling is going, so you can make changes right away to get the best results. These advances in technology make forecast repair methods possible, which extend the life of bits while causing as few problems as possible with operations.

By knowing how the market is changing, you can plan your purchases in a way that takes into account changes in technology and the supply chain. Investing in environmentally friendly drilling methods helps meet changing environmental standards while keeping operations running smoothly. High-efficiency drilling options give businesses an edge over their competitors by lowering costs and speeding up project timelines.

The method of competitive price with unwavering quality is a big market trend that procurement experts can benefit from, including for the Oil Diamond Drill Bit. Strict quality control measures make sure that performance is always the same, and modern manufacturing methods lower the cost of making things. These changes make it easier for suppliers and drilling companies that want solid, cost-effective drilling solutions, such as the Oil Diamond Drill Bit, to work together for a long time.

Conclusion

Oil Diamond Drill Bit field uses show clear benefits for modern drilling operations that want to improve performance and cut costs. The in-depth study shows that the product has better longevity, consistent performance, and operating freedom that supports a wide range of drilling tasks in the mining, building, and oil and gas industries. Putting money into good diamond drill bit technology pays off in a big way: lower operating costs, longer bit life, and better drilling efficiency. For business-to-business clients, the value offer is best when strategic buying methods focus on supplier skills, customization choices, and the benefits of bulk shopping. The diamond drill bit technology keeps getting better, which means that future drilling activities will be more productive and cost-effective.

FAQ

1. What formations are oil diamond drill bits best suited for?

Oil Diamond Drill Bits are best suited for medium to hard and abrasive formations, including limestone, sandstone, shale, dolomite, and gypsum. Their diamond-impregnated cutting structure provides consistent cutting performance and superior wear resistance, making them ideal for complex geological conditions commonly encountered in oil and gas drilling.

2. How do I select the right oil diamond drill bit for my drilling operation?

Selecting the right oil diamond drill bit depends on several key factors, such as formation hardness, abrasiveness, well profile (vertical, directional, or horizontal), operating RPM, weight on bit (WOB), and circulation requirements. For optimal results, many operators choose customized or OEM-designed bits tailored to specific formations and drilling parameters.

3. Are oil diamond drill bits cost-effective for long-term drilling projects?

Yes. Although oil diamond drill bits typically have a higher initial cost than conventional drill bits, they offer a lower total cost of ownership (TCO). Their longer service life, reduced replacement frequency, stable penetration rates, and minimized non-productive time (NPT) make them highly cost-effective for long-term and large-scale drilling projects.

Upgrade Your Drilling Performance with High-Efficiency Oil Diamond Drill Bits | HNS

HNS offers cutting edge oil diamond drill bit technology that will help you get the most out of your drilling activities by making them more reliable and effective. Our wide range of products includes patterns that can be changed to fit different rock formations. They are backed by strict quality control and reasonable prices. Get in touch with our technical team at hainaisen@hnsdrillbit.com to talk about your unique drilling needs and find out how our skills as an oil diamond drill bit maker can help you cut costs and improve drilling efficiency.

References

1. Smith, J.R., et al. "Advanced Diamond Technology in Modern Drilling Operations." Journal of Petroleum Engineering Technology, Vol. 45, 2023, pp. 123-140.

2. Johnson, M.K. "Comparative Analysis of Diamond Drill Bit Performance in Oil and Gas Applications." International Drilling Review, Issue 3, 2024, pp. 67-89.

3. Williams, S.T. "Optimization Strategies for Diamond Drill Bit Operations in Challenging Formations." Energy Technology Quarterly, Vol. 28, No. 2, 2023, pp. 45-62.

4. Brown, A.L., et al. "Economic Analysis of Diamond Drill Bit Technology in B2B Procurement." Industrial Procurement Management, Vol. 15, 2024, pp. 234-251.

5. Davis, R.H. "Future Trends in Diamond Drilling Technology for Oil and Gas Exploration." Petroleum Technology Advances, Vol. 39, 2023, pp. 156-173.

6. Taylor, K.M. "Maintenance Best Practices for Extended Diamond Drill Bit Performance." Drilling Operations Management, Issue 4, 2024, pp. 78-95.