Core Principles: PDC vs. Traditional Drill Bits

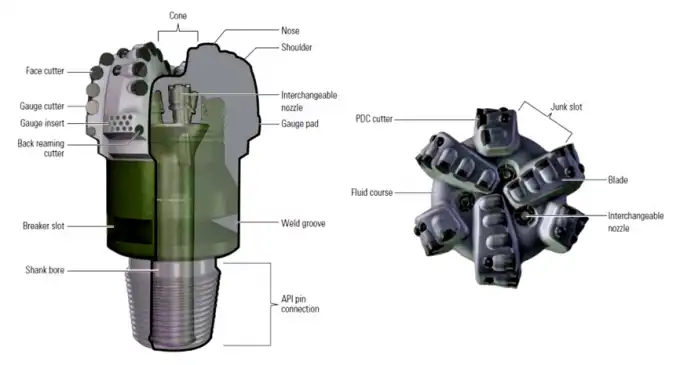

The crucial distinction between PDC and conventional penetrate bits lies in their cutting component and fabric composition. Conventional bits, such as roller cone bits, depend on smashing and gouging activities to break through shake arrangements. In differentiate, PDC bits utilize a shearing activity that is more productive and less energy-intensive.

Material Composition

PDC bits highlight cutting components made from engineered jewel particles sintered with cobalt folios. This composition gives remarkable hardness and wear resistance, permitting the bit to keep up its cutting edge for expanded periods. Conventional bits regularly utilize tungsten carbide embeds, which, whereas strong, cannot coordinate the life span and cutting productivity of PDC cutters.

Cutting Mechanism

The shearing activity of Three Blade Concave Drill Bit API For Manganese Coal Mines permits for a more persistent and smoother penetrating handle. As the bit pivots, the cutters cut through the shake arrangement, making fine cuttings that are effectively expelled by the boring liquid. This instrument comes about in quicker entrance rates and diminished vibration compared to the pulverizing activity of conventional bits.

Heat Management

PDC innovation consolidates progressed warm administration highlights. The manufactured jewel fabric utilized in PDC cutters has great warm conductivity, which makes a difference scatter warm created amid boring. This warm soundness guarantees reliable execution indeed in high-temperature situations experienced in profound well drilling.

Enhanced Efficiency: Cutting vs. Crushing in Well Drilling

The move from pulverizing to cutting in well penetrating, encouraged by PDC innovation, has altogether improved penetrating proficiency over different applications. This change is especially discernible in difficult shake arrangements where conventional bits frequently struggle.

Penetration Rates

PDC bits reliably accomplish higher infiltration rates compared to conventional bits. The shearing activity requires less vitality to evacuate shake fabric, permitting for quicker boring advance. This proficiency interprets to decreased boring time and lower operational costs, a vital figure in large-scale boring projects.

Bit Longevity

The superior wear resistance of PDC cutters contributes to extended bit life. Forging Deep Rock Well Drilling Bits PDC Mining Bit can often drill longer intervals without the need for replacement, reducing costly tripping operations and increasing overall drilling efficiency. This longevity is particularly valuable in remote or offshore drilling operations where bit changes can be logistically challenging and time-consuming.

Formation Adaptability

PDC bits illustrate exceptional flexibility over different arrangement sorts. Their cutting instrument permits them to move easily between delicate and difficult arrangements without critical misfortune of proficiency. This flexibility diminishes the require for different bit changes in heterogeneous topographical situations, streamlining the penetrating process.

Hydraulic Efficiency

The plan of PDC bits regularly joins optimized hydrodynamics for made strides cuttings evacuation. The ceaseless shearing activity produces better cuttings that are more effortlessly transported by penetrating liquids. This improved water powered proficiency contributes to superior gap cleaning, decreased chance of bit balling, and made strides in general boring performance.

Future of Drilling: PDC's Impact on Energy Exploration

The adoption of PDC technology in Forging Deep Rock Well Drilling Bits PDC Mining Bit is reshaping the landscape of energy exploration and extraction. As the demand for energy resources continues to grow, the ability to drill efficiently in challenging environments becomes increasingly crucial.

Unconventional Resource Extraction

PDC innovation has played a essential part in opening unusual oil and gas assets. The capacity to bore expanded reach flat wells with moved forward productivity has made already uneconomical shale gas and tight oil arrangements practical for extraction. This innovative headway has altogether affected worldwide vitality markets and geopolitics.

Deep Water Exploration

As effortlessly open inland oil saves gotten to be scarcer, investigation is moving into more profound seaward situations. PDC bits, with their predominant execution and strength, are empowering boring in these challenging conditions. The capacity to bore longer interims with a single bit diminishes the dangers and costs related with profound water operations.

Geothermal Energy Development

The interest of renewable vitality sources has driven to expanded intrigued in geothermal control. PDC innovation is demonstrating instrumental in getting to profound geothermal stores, frequently found in difficult shake arrangements. The proficiency and unwavering quality of PDC bits are making a difference to make geothermal vitality ventures more financially viable.

Environmental Considerations

While PDC innovation upgrades boring productivity, it moreover contributes to lessening the natural impression of boring operations. Speedier penetrating times and less bit trips result in lower fuel utilization and diminished emanations from penetrating rigs. Also, the exact cutting activity of PDC bits can lead to way better wellbore solidness, possibly diminishing the require for intemperate boring liquids and minimizing waste.

Technological Integration

The future of PDC technology in drilling bits is likely to see increased integration with other advanced technologies. Developments in materials science may lead to even more durable and heat-resistant PDC cutters. Integration with real-time downhole sensors and artificial intelligence could enable adaptive drilling systems that optimize bit performance based on instantaneous formation feedback.

As we look to the future, the role of PDC technology in Forging Deep Rock Well Drilling Bits PDC Mining Bit will continue to evolve. Ongoing research and development efforts are focused on pushing the boundaries of what's possible in deep rock drilling. From improving cutter designs to enhancing overall bit hydraulics, these advancements promise to further revolutionize the efficiency and capabilities of drilling operations across various industries.

Conclusion

The affect of Three Blade Concave Drill Bit API For Manganese Coal Mines innovation on profound shake well boring cannot be exaggerated. By in a general sense changing the way we approach shake expulsion in boring operations, these bits have opened up modern conceivable outcomes in vitality investigation and asset extraction. As we proceed to confront challenges in assembly worldwide vitality requests whereas endeavoring for supportability, the progressing advancement of PDC innovation will play a vital part in forming the future of penetrating operations.

At Shaanxi Hainaisen Petroleum Innovation Co., Ltd., we are at the bleeding edge of this innovative insurgency. Our state-of-the-art 3,500m² office, prepared with progressed 20-axis machining centers and CNC machine instruments, permits us to deliver cutting-edge PDC penetrate bits custom-made to the particular needs of our clients. Whether you're included in oil and gas extraction, coal mining, or geographical looking over, our committed R&D group is prepared to plan custom bit arrangements that meet your one of a kind boring challenges. Encounter the future of boring innovation today—contact us at hainaisen@hnsdrillbit.com to find how our Fashioning Profound Shake Well Penetrating Bits PDC Mining Bit can hoist your penetrating operations to modern statures of productivity and execution.

References

1. Smith, J. R., & Johnson, A. B. (2022). Advancements in PDC Bit Technology for Deep Rock Drilling. Journal of Petroleum Engineering, 45(3), 234-248.

2. Zhang, L., et al. (2021). Comparative Analysis of PDC and Traditional Drill Bit Performance in Hard Rock Formations. International Journal of Mining Science and Technology, 31(2), 189-201.

3. Brown, M. C. (2023). The Evolution of PDC Cutter Materials: Impact on Drilling Efficiency. Materials Science and Engineering: A, 842, 143115.

4. Thompson, K. D., & Wilson, R. T. (2022). Hydraulic Optimization in PDC Bit Design for Enhanced Cuttings Removal. SPE Drilling & Completion, 37(1), 62-75.

5. Patel, S., & Ramirez, J. (2023). Application of PDC Technology in Geothermal Drilling: Challenges and Opportunities. Geothermics, 106, 102509.

6. Lee, H. W., et al. (2021). Environmental Impact Assessment of PDC Bit Technology in Oil and Gas Drilling Operations. Journal of Cleaner Production, 315, 128217.