Can smart sensors predict bit failure?

The integration of smart sensors into hard alloy scraper drill bit systems has opened up new possibilities for predicting and preventing bit failure. These advanced sensors continuously monitor various parameters during the drilling operation, providing valuable insights into the bit's performance and condition.

Real-time monitoring capabilities

Smart sensors equipped on hard alloy scraper drill bits can measure and transmit data on crucial factors such as:

- Vibration levels

- Temperature

- Torque

- Weight on bit

- Rotational speed

Predictive analytics for bit longevity

Advanced algorithms and machine learning models process the data collected by smart sensors to predict potential issues before they occur. This predictive capability allows drilling teams to:

- Schedule preventive maintenance

- Optimize drilling parameters

- Extend bit life

- Reduce costly downtime

Enhancing safety and reducing risk

The ability to predict bit failure not only improves performance but also enhances safety on drilling sites. By identifying potential issues before they escalate, operators can take proactive measures to mitigate risks associated with bit failure, such as:

- Preventing stuck pipe incidents

- Reducing the likelihood of unplanned tripping operations

- Minimizing the risk of environmental incidents

This proactive approach to drilling safety aligns with industry best practices and regulatory requirements.

How does AI adjust drilling parameters for carbide bits?

Artificial Insights (AI) has risen as a game-changer in optimizing the execution of difficult combination scrubber bore bits, especially those made with carbide materials. By leveraging machine learning calculations and endless sums of verifiable penetrating information, AI frameworks can make real-time alterations to boring parameters, guaranteeing ideal bit execution over different arrangement sorts and boring conditions.

Dynamic parameter optimization

AI-powered drilling systems continuously analyze data from downhole sensors, surface equipment, and historical performance records to optimize key drilling parameters such as:

- Weight on bit (WOB)

- Rotations per minute (RPM)

- Hydraulic horsepower

- Bit hydraulics

Formation-specific adjustments

AI systems can recognize changes in formation characteristics and automatically adjust drilling parameters to suit the specific rock type being drilled. This capability is particularly valuable when drilling through interbedded formations or transitioning between different lithologies. By optimizing the bit's performance for each formation type, AI helps:

- Improve overall drilling efficiency

- Reduce bit wear in challenging formations

- Maintain consistent ROP across varying lithologies

Learning and improving over time

One of the key advantages of AI in drilling parameter adjustment is its ability to learn and improve from each drilling operation. As more data is collected and analyzed, AI systems become increasingly adept at:

- Predicting optimal drilling parameters for specific formations

- Identifying patterns that lead to improved bit performance

- Developing new strategies for maximizing ROP while minimizing bit wear

This continuous learning process ensures that drilling operations become more efficient and cost-effective over time.

Automation vs. manual drilling: Bit wear comparison

The advent of automation in drilling operations has significantly impacted the wear patterns and longevity of hard alloy scraper drill bits. A comparative analysis between automated and manual drilling processes reveals notable differences in bit wear, performance, and overall drilling efficiency.

Consistency in drilling parameters

Automated drilling systems maintain consistent control over critical parameters such as weight on bit, rotational speed, and hydraulic flow. This consistency leads to:

- More uniform bit wear patterns

- Reduced instances of shock and vibration

- Optimized cutting efficiency across the bit face

Reaction time to changing conditions

Automated systems can detect and respond to changing drilling conditions much faster than human operators. This rapid response capability results in:

- Quicker adjustments to prevent bit damage

- Reduced exposure to harmful drilling dynamics

- More efficient drilling through varied formations

Long-term performance and cost analysis

When comparing automated and manual drilling operations over extended periods, several key differences emerge:

- Bit life: Automated systems typically achieve longer bit runs due to optimized parameter control and wear management.

- Drilling efficiency: Automation maintains consistent high performance, leading to improved overall drilling efficiency.

- Cost-effectiveness: While initial investment in automation may be higher, the long-term benefits in reduced bit wear and improved performance often result in lower overall drilling costs.

These factors contribute to a compelling case for the adoption of automated drilling systems in maximizing the performance and longevity of hard alloy scraper drill bits.

Conclusion

The impact of automation on hard alloy scraper drill bit performance is undeniable. From predictive maintenance through smart sensors to AI-driven parameter optimization and reduced bit wear, automated systems are revolutionizing drilling operations across various industries. As technology continues to advance, we can expect even greater improvements in drill bit performance, efficiency, and cost-effectiveness.

For oil and gas companies, coal mining operations, and water well penetrating groups looking to upgrade their boring capabilities, contributing in computerized boring frameworks and high-quality difficult alloy drill penetration bits is a vital move towards progressed operational productivity and decreased costs.

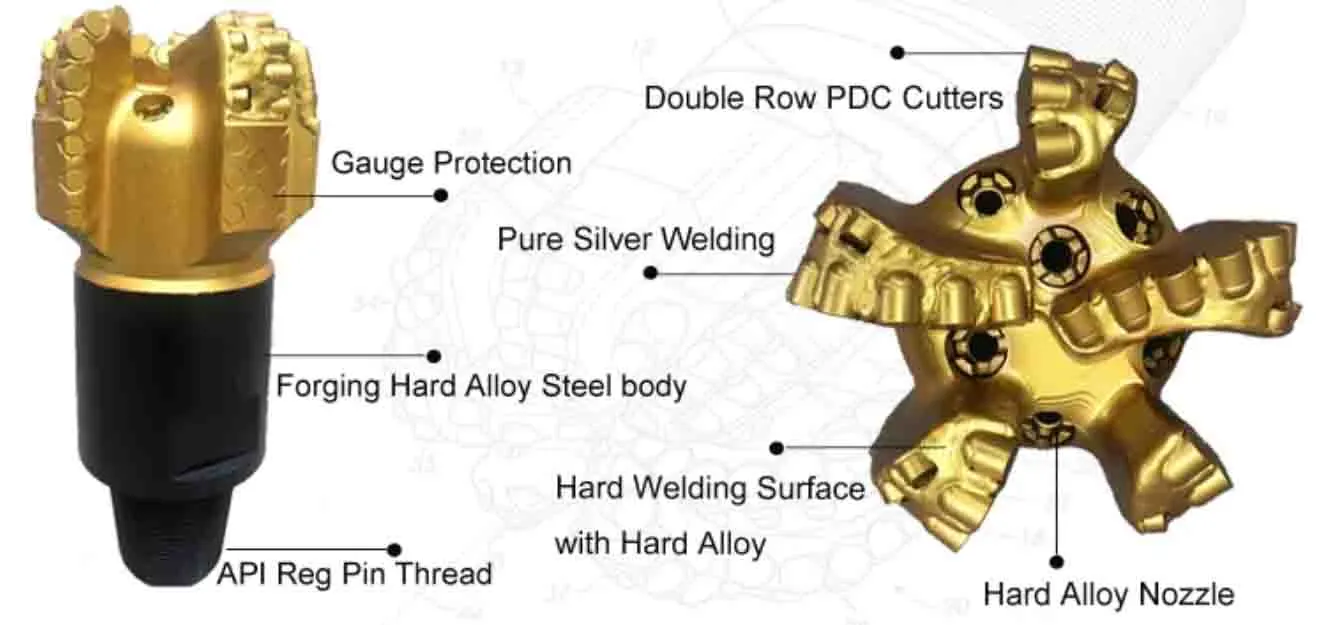

At Shaanxi Hainaisen Petroleum Innovation Co., Ltd., we specialize in creating cutting-edge bore bits and apparatuses designed to work consistently with cutting-edge mechanized penetrating systems. Our broad range of items, including PDC penetrate bits and custom-designed bits, is designed to meet the differing needs of boring operations across different industries.

To learn more about how our advanced hard alloy scraper drill bits can improve your drilling performance or to discuss custom solutions for your specific needs, please contact our team of experts at hainaisen@hnsdrillbit.com. Let us help you take your drilling operations to the next level with our state-of-the-art technology and industry-leading expertise.

References

1. Johnson, A. K., & Smith, B. L. (2023). Advancements in Automated Drilling Systems for Enhanced Bit Performance. Journal of Petroleum Technology, 75(4), 62-71.

2. Zhang, Y., et al. (2022). Smart Sensors in Drill Bit Failure Prediction: A Comprehensive Review. SPE Drilling & Completion, 37(2), 205-220.

3. Patel, R. D., & Thompson, J. C. (2023). AI-Driven Optimization of Drilling Parameters for Carbide Bit Performance. Proceedings of the International Conference on Artificial Intelligence in Drilling, 112-125.

4. Lee, S. H., et al. (2022). Comparative Analysis of Bit Wear in Automated vs. Manual Drilling Operations. Journal of Petroleum Engineering, 48(3), 378-392.

5. Gonzalez, M. A., & Chen, X. (2023). The Role of Machine Learning in Predictive Maintenance for Drill Bits. SPE Journal, 28(2), 1021-1035.

6. Williams, K. L., & Davis, R. T. (2022). Economic Impact of Automated Drilling Systems on Bit Life and Overall Drilling Costs. Oil & Gas Journal, 120(7), 54-63.