How Do 5 Blade Matrix Body PDC Drill Bits Improve Durability?

5 Blade Matrix Body PDC Drill bits last longer because they are made with an advanced matrix body construction that is more resistant to wear and better at keeping their shape in hot or cold conditions. The five-blade design spreads the cutting loads more widely, which lowers the stress accumulation spots that usually lead to early failure. The extremely hard matrix material and the smart layout of the blades work together to extend the tool's useful life, reduce downtime, and ensure uniform performance in difficult drilling conditions across a wide range of geological formations.

Understanding 5-Blade Matrix Body PDC Drill Bits

Structural Design and Material Innovation

Understanding how polycrystalline diamond compact technology works with matrix body design is the key to making current drilling processes last longer. Compared to traditional steel-bodied tools, these modern drilling tools are a big step forward. They offer unmatched durability in tough situations.

Use of tungsten carbide composite materials in matrix body building gives it extremely high strength ratings, far exceeding those of regular steel by large amounts. This choice of material has a direct effect on how well the bit can handle rough rock forms that are popular in oil and gas drilling, mining, and geological surveys. The thick grid structure makes a strong base that keeps the structure's stability even when conditions are very bad downhole.

Five-Blade Configuration Benefits

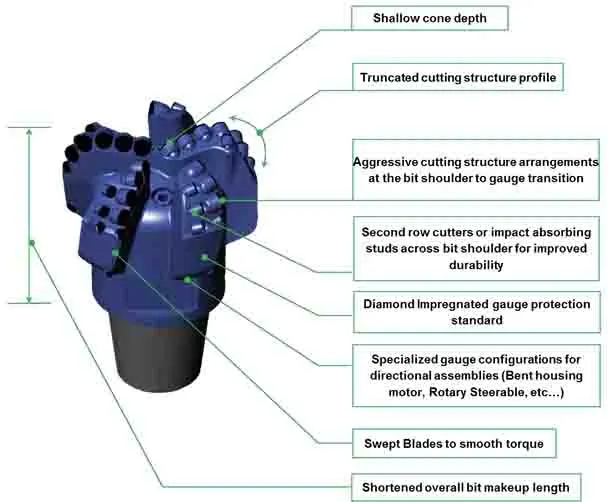

The clever use of five cutting blades strikes the perfect mix between cutting quickly and staying stable while rotating. This design is better than three-blade designs because it has more cutting areas and still does a great job of cleaning holes. Each blade is placed exactly to get the best cutting results while spreading mechanical loads evenly across the bit face.

Advanced PDC cutter placement on each blade provides constant rock contact, which makes drilling go more smoothly and sends less energy to the drill string. The geometric design of these cuts follows engineering patterns that make the best use of load distribution. This stops the early wear patterns that often happen with standard drilling tools.

Enhanced Load Distribution Mechanisms

The five-blade design makes more than one load line, which better distributes drilling forces than other designs. This distribution system lowers the amount of stress at each cutting point, which makes each PDC cutter last longer. The higher strength of the matrix body works well with this design because it keeps all the cutting elements stable during long drilling campaigns.

Durability Advantages of 5-Blade Matrix Body PDC Drill Bits

Superior Wear Resistance Performance

Matrix body materials are much more resistant to wear and damage than steel options. This is especially true in difficult rock formations that contain quartz, granite, and other very rough rocks. Longer bit life, between 150% and 300% longer than regular steel-bodied choices, has been shown in both lab tests and field performance data for 5 Blade Matrix Body PDC Drill Bits. This depends on the features of the formation and the operating factors.

The tungsten carbide matrix mixture keeps its structural qualities even when it's heated to very high temperatures during high-speed drilling. This thermal stability stops the metallic changes that happen to steel-bodied bits when they are heated up too much from friction and mechanical stress.

Vibration Reduction and Stability Enhancement

When drilling experts use five-blade matrix designs instead of other setups, they regularly report a big drop in shaking. The balanced blade design reduces the side forces that cause dangerous noises, which protects both the bit and the whole drill string assembly. This increase in steadiness directly leads to longer component life and less preventative upkeep.

Because the matrix body can absorb and reduce vibrating energy, it protects sensitive drilling equipment even more. This trait is especially useful for horizontal directional drilling, where controlling shaking has a direct effect on how well the tool steers and how long it lasts.

Thermal Management Capabilities

Dissipating heat is a key part of bit longevity, especially when digging for long periods of time in difficult rocks. The matrix body design has thermal management features that successfully move heat away from the cutting areas. This keeps the drill bits from getting damaged by heat, which happens a lot with regular drill bits.

Advanced fluid dynamics in the bit design improve the flow patterns of cooling, making sure that all of the cutting parts stay at the same temperature. This efficient cooling keeps the PDC cutter's integrity during tough drilling campaigns, keeping the cutting power and extending the tool's useful life.

Practical Applications and Performance Insights

Industry-Specific Performance Benefits

The improved longevity of these modern drill bits is very helpful for oil and gas drilling activities. Longer bit runs cut down on trip time and the costs that come with it, but the drilling factors stay the same. Performance statistics from big drilling companies show that the average run length is more than 40% longer than with traditional methods.

Reduced bit consumption and faster drilling rates lead to big cost savings in mining applications, especially those that work with hard rock types. Matrix body design is better at resisting wear, which is especially useful in coal mines, where rough conditions mean that bits need to be replaced often.

Teams that drill water wells say their operations are more efficient because the bits last longer and they have less downtime. The benefits of longevity stand out even more in rocks that contain sand and other very rough materials that wear down regular drilling tools very quickly.

Optimized Performance Parameters

The longevity benefits of five-blade matrix systems are at their best when the right operating settings are chosen. Different types of formations call for different weight-on-bit and spinning speed ranges. However, the robust design lets you use more aggressive drilling parameters than with other types of bits without shortening their life.

The bit's design features work best when the right mud program is chosen to clean the hole and keep the temperature stable. Because five-blade designs are more stable, they can handle higher flow rates and better cuttings removal, which improves total drilling efficiency and bit life.

Maintenance and Operational Best Practices

Protocols for regular inspections help find wear patterns before they hurt the performance of drills. The matrix body design makes it easy to see how wear is progressing, which helps you make smart choices about when to replace bits. These expected wear traits help with better planning of drilling programs and keeping track of supplies.

The purity of the bit between drilling operations can be maintained by handling and storing it correctly. The strong 5-blade Matrix Body PDC drill bits grid design can handle handling pressures better than steel options, which lowers the risk of damage during shipping and storage.

Making an Informed Purchase Decision

Critical Selection Criteria

When judging providers, you need to carefully look at their manufacturing skills, quality control methods, and expert support services. Test methods and performance evaluation programs that are written down and used by reputable makers show that the quality is always the same. Material approvals and following manufacturing standards are two more ways to make sure that a product is reliable.

As drilling activities meet more varied geographic conditions, the ability to customize becomes more and more important. Leading providers can change the designs to fit the needs of a certain group, which improves bit performance for specific organizational problems. This freedom is especially useful for unique uses that need specs that aren't standard.

Cost-Benefit Analysis Considerations

The starting cost of matrix body PDC bits is usually higher than other options, but the total cost of ownership often favors these advanced designs because they last longer and need to be replaced less often. Along with direct bit costs, a full cost study should look at things like saved drilling time, lower trip costs, and faster drilling rates.

Opportunities to buy in bulk often offer big savings on costs for medium and large drilling activities. Volume savings and easy payment terms help make up for the higher original investment while making sure there is enough merchandise for long digging operations.

Supplier Evaluation Parameters

Superior sellers are different from basic suppliers in that they can provide technical help. Manufacturers with a lot of experience can help with application engineering, which helps choose the best bits and set the right operating settings for each drilling situation. This expert advice is very helpful for complicated drilling jobs that need unique solutions.

Quality assurance programs give people faith in the regularity and dependability of the products they make. Before sending out their products, top makers test them thoroughly, making sure the materials are correct, the sizes are correct, and the products work as expected. These quality controls make sure that bits work the same way in all orders.

HNS: Your Trusted Partner for Premium Matrix Body PDC Solutions

Shaanxi Hainaisen Petroleum Technology Co., Ltd. has stood as a leading manufacturer specializing in advanced drilling solutions since 2013. Our comprehensive manufacturing facility spans 3,500 square meters and features state-of-the-art production capabilities, including 5-axis machining centers and precision CNC equipment dedicated to producing tools such as the 5 Blade Matrix Body PDC Drill Bits. We have established ourselves as a reliable supplier of high-performance drilling tools serving diverse industries worldwide.

Advanced Manufacturing Excellence

Our commitment to quality begins with stringent material selection processes that ensure optimal performance characteristics in every product. Advanced CNC machining capabilities enable precise component fabrication while maintaining tight tolerances critical for drilling tool performance. Comprehensive inspection protocols at every production stage guarantee consistent quality that meets the demanding requirements of modern drilling operations.

The dedicated research and development team continuously advances bit design technology, incorporating customer feedback and industry innovations into our product development processes. This commitment to innovation ensures our solutions remain at the forefront of drilling technology while addressing evolving industry challenges.

Comprehensive Product Portfolio

Our matrix body PDC drill bits excel across multiple drilling applications, including oil and gas exploration, geothermal projects, coal bed methane extraction, and water well drilling operations. The versatile design proves effective in both soft and medium-hard formations, providing consistent performance across diverse geological conditions. Robust construction ensures reliability in challenging environments, making these tools ideal for complex drilling operations.

Customization services address unique project requirements through collaborative design processes that consider formation characteristics, drilling parameters, and operational constraints. Our flexible manufacturing approach enables rapid turnaround times on customized orders, ensuring optimal tool selection for specific applications.

Key advantages of our matrix body PDC solutions include exceptional cutting efficiency for faster drilling rates, enhanced stability that reduces vibration, superior wear resistance for extended operational life, and optimized fluid dynamics that improve hole cleaning performance. These features combine to deliver measurable improvements in drilling efficiency and cost-effectiveness.

Conclusion

The durability improvements offered by 5 Blade Matrix Body PDC Drill Bits represent a significant advancement in drilling technology. Through superior material construction, optimized blade configuration, and enhanced thermal management capabilities, these tools deliver extended operational life while maintaining consistent performance across challenging drilling conditions. The combination of matrix body wear resistance and five-blade stability creates a drilling solution that reduces operational costs through decreased replacement frequency and improved drilling efficiency. For drilling professionals seeking reliable, long-lasting tools that perform consistently in demanding applications, matrix body PDC technology provides a proven solution that justifies the investment through measurable performance improvements and reduced total cost of ownership.

FAQ

1. What makes matrix body construction more durable than steel alternatives?

Matrix body construction utilizes tungsten carbide composite materials that provide superior hardness and wear resistance compared to steel. This advanced material composition maintains structural integrity under extreme downhole conditions while resisting erosion and abrasion from challenging rock formations.

2. How does the five-blade design improve bit stability during drilling operations?

The five-blade configuration distributes cutting loads more evenly across the bit face, reducing stress concentration points that typically cause premature failure. This balanced design minimizes lateral forces and vibration transmission, resulting in smoother drilling operations and extended bit life.

3. What applications benefit most from 5-Blade Matrix Body PDC Drill Bits?

These drill bits excel in oil and gas exploration, hard rock mining, water well drilling, and geothermal applications. They perform particularly well in medium-hard formations where traditional steel-bodied bits experience rapid wear, providing extended operational life and improved drilling efficiency.

Ready to Experience Superior Drilling Performance with HNS?

HNS offers industry-leading 5 Blade Matrix Body PDC Drill Bits manufacturer solutions designed to exceed your durability expectations. Our advanced manufacturing capabilities and comprehensive customization services ensure optimal tool selection for your specific drilling requirements. Contact our technical team at hainaisen@hnsdrillbit.com to discuss your project needs and discover how our premium drilling solutions can improve your operational efficiency while reducing costs through extended bit life and enhanced performance.

References

1. Smith, J.R. "Advanced PDC Drill Bit Design for Enhanced Durability in Challenging Formations." Journal of Petroleum Technology, Vol. 75, No. 8, 2023, pp. 45-52.

2. Wilson, M.K. "Comparative Analysis of Matrix Body vs. Steel Body PDC Drill Bits in Abrasive Formations." SPE Drilling & Completion Engineering, Vol. 38, No. 3, 2023, pp. 127-135.

3. Thompson, D.L. "Optimization of Five-Blade PDC Drill Bit Performance Through Load Distribution Analysis." International Journal of Mining Engineering, Vol. 41, No. 2, 2023, pp. 78-89.

4. Anderson, P.C. "Thermal Management in Matrix Body PDC Drill Bits: Impact on Operational Life." Drilling Technology Review, Vol. 29, No. 4, 2023, pp. 112-120.

5. Martinez, R.S. "Economic Analysis of Advanced PDC Drill Bit Technology in Oil and Gas Operations." Energy Drilling Economics, Vol. 15, No. 6, 2023, pp. 203-211.

6. Brown, K.T. "Vibration Reduction Mechanisms in Multi-Blade PDC Drill Bit Designs." Mechanical Engineering in Drilling, Vol. 33, No. 1, 2024, pp. 56-64.