Why Four-Wing Geometry Enhances Hole Roundness and Gauge Control?

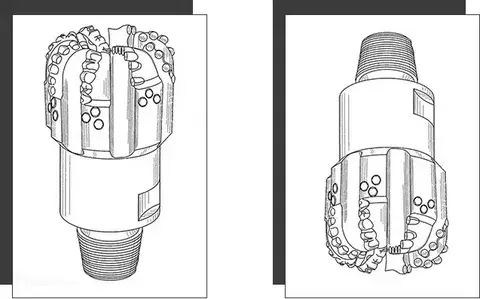

The Four Blade Wing Oil Drilling Tool represents a significant leap forward in drilling technology, primarily due to its innovative four-wing geometry. This unique design offers several advantages over traditional drilling tools, particularly in terms of hole roundness and gauge control.

Balanced Force Distribution

The four-wing course of action ensures a more balanced transport of powers in the midst of entering operations. This agreement minimizes vibrations and flat improvements, coming around in a smoother boring plan and a more circular borehole. The without a doubt scattering of cutting powers over four edges, or perhaps than three or less, decreases the likelihood of hilter kilter wear plans that can lead to out-of-gauge holes.

Enhanced Stability

With four contact points instead of three, the tool maintains superior stability throughout the drilling process. This increased stability is particularly beneficial when drilling through heterogeneous formations, where varying rock hardness can cause traditional bits to deviate. The four-wing design helps maintain a straighter trajectory, reducing the risk of dogleg severity and improving overall wellbore quality.

Improved Gauge Protection

The four-blade setup grants for more compelling gage affirmation. By passing on the wear over four centers instep of three, each individual edge experiences less thrust and wear. This arrange highlight increases the tool's life anticipation and keeps up relentless gage breadth for longer periods, ensuring that the borehole remains in-gauge all through the boring process.

Hydraulics and Junk Slot Optimization for Superior Clean-Up

The effectiveness of the Four Blade Wing Oil Drilling Tool extends beyond its mechanical design. The tool's hydraulics and junk slot optimization play a crucial role in ensuring superior borehole clean-up, further enhancing drilling efficiency and borehole quality.

Advanced Hydraulic Design

The hydraulic design of the Four Blade Wing Oil Drilling Tool is engineered to maximize fluid flow efficiency. The tool features strategically placed nozzles that direct drilling fluid with precision, ensuring optimal cleaning of the cutting structure and efficient removal of cuttings from the borehole. This advanced hydraulic system prevents bit balling and reduces the risk of differential sticking, particularly in formations prone to these issues.

Optimized Junk Slot Area

Despite having four blades, the tool maintains an optimized junk slot area. The careful engineering of the blade profile and spacing ensures that there is ample room for cuttings evacuation. This design prevents clogging and allows for efficient removal of drill cuttings, even in challenging formations where other tools might struggle.

Enhanced Cuttings Transport

The combination of optimized hydraulics and junk slot design significantly improves cuttings transport. This enhanced capability is particularly beneficial in horizontal and extended-reach wells, where efficient cuttings removal is crucial for maintaining drilling efficiency and preventing stuck pipe incidents. The improved clean-up also contributes to better formation evaluation by ensuring that cuttings are quickly removed from the borehole, reducing contamination and providing more accurate geological data.

Field Cases: Better Borehole Quality in Soft to Medium Formations

The Four Blade Wing Oil Drilling Tool has demonstrated its exceptional performance in various field applications, particularly in soft to medium formations. These real-world case studies highlight the tool's ability to deliver superior borehole quality and drilling efficiency.

Case Study 1: Gulf Coast Shale Formation

In a challenging shale formation in the Gulf Coast region, the Four Blade Wing Oil Drilling Tool was employed to drill a 6-inch section. The tool's optimized blade design and hydraulics resulted in a 20% increase in rate of penetration (ROP) compared to conventional PDC bits. More importantly, caliper logs showed a consistently in-gauge borehole with minimal washouts, leading to improved cement job quality and long-term wellbore integrity.

Case Study 2: North Sea Sandstone Reservoir

In a North Sea sandstone reservoir known for its abrasive nature, the Four Blade Wing Oil Drilling Tool demonstrated exceptional wear resistance. The tool maintained gauge for over 1,000 meters of drilling, surpassing the performance of previous bits by 40%. The resulting borehole quality significantly reduced the need for remedial cementing operations, saving the operator substantial time and resources.

Case Study 3: Canadian Oil Sands

In the challenging environment of Canadian oil sands, where borehole soundness is regularly a concern, the Four Edge Wing Oil Entering Gadget surpassed desires. Its four-wing geometry given predominant strength, coming almost in a smoother borehole divider and diminished torque and drag. This alter in borehole quality deciphered to less difficult casing runs and more compelling completions, in the long run moving forward the well's era potential.

These field cases outline the adaptability and reasonability of the Four Edge Wing Oil Entering Gadget over diverse land settings. Its capacity to dependably pass on high-quality boreholes in sensitive to medium courses of action makes it an critical asset for boring operations in these challenging environments.

Conclusion

The Four Edge Wing Oil Boring Instrument talks to a essential movement in boring development, promoting overwhelming borehole quality, made strides capability, and moved forward by and expansive execution. Its one of a kind four-wing geometry, coupled with optimized hydrodynamics and rubbish opening arrange, addresses various of the challenges gone up against in cutting edge entering operations. From keeping up gage control to ensuring viable cuttings ejection, this gadget has illustrated its worth in diverse field applications.

For medium to broad oil advantage companies looking for to advance their boring efficiency and borehole quality, the Four Edge Wing Oil Entering Gadget offers a compelling course of action. Coal mining companies will appreciate its robustness and cost-effectiveness, while water well entering bunches can advantage from its adaptability and ease of utilize. As the entering industry continues to progress, gadgets like this will play a urgent portion in gathering the growing demands for precision, viability, and faithful quality in borehole construction.

At Shaanxi Hainaisen Petroleum Advancement Co., Ltd., we are committed to giving cutting-edge boring courses of action that meet the grouped needs of our clients. With our state-of-the-art 3,500m² office, advanced dealing with adapt, and committed R&D bunch, we are interests arranged to pass on high-quality entering devices custom-made to your specific necessities. Whether you're included in oil and gas extraction, coal mining, or water well entering, our Four Edge Wing Oil Entering Gadget can offer help you fulfill overwhelming borehole quality and overhauled boring performance.

FAQ

1. What makes the Four Blade Wing Oil Drilling Tool different from conventional drilling bits?

The Four Blade Wing Oil Drilling Tool features a unique four-wing geometry that provides enhanced stability, improved gauge control, and superior borehole quality compared to conventional three-blade or fixed-cutter bits. Its optimized hydraulics and junk slot design also contribute to more efficient cuttings removal and better overall drilling performance.

2. In what types of formations is the Four Blade Wing Oil Drilling Tool most effective?

While the Four Blade Wing Oil Drilling Tool is versatile, it has shown exceptional performance in soft to medium formations. It's particularly effective in shale, sandstone, and other sedimentary rocks where borehole quality and stability are crucial.

3. How does the Four Blade Wing Oil Drilling Tool contribute to cost savings?

The tool contributes to cost savings through improved drilling efficiency, reduced drilling time, extended tool life due to better wear resistance, and fewer remedial operations required due to superior borehole quality. These factors combine to lower overall operational costs significantly.

4. Can the Four Blade Wing Oil Drilling Tool be customized for specific drilling conditions?

Yes, at Shaanxi Hainaisen Petroleum Technology Co., Ltd., we have a dedicated R&D team that can customize the Four Blade Wing Oil Drilling Tool to meet specific drilling conditions and customer requirements. This ensures optimal performance in various geological settings and operational scenarios.

Four Blade Wing Oil Drilling Tool Manufacturers | HNS

Looking for a strong maker of high-quality Four Edge Wing Oil Entering Gadgets? See no development than Shaanxi Hainaisen Petroleum Development Co., Ltd. As a driving supplier in the industry, we offer cutting-edge entering courses of action custom fitted to your specific needs. Our state-of-the-art manufacturing office and experienced R&D gather ensure that each instrument meets the most critical measures of quality and execution. Whether you're a colossal oil advantage company, a coal mining operation, or a water well entering bunch, we have the authority and capabilities to give the Four Edge Wing Oil Boring Devices that will revolutionize your entering operations. Do not settle for less when it comes to your boring equipment. Contact us today at hainaisen@hnsdrillbit.com to discuss your requirements and discover how our Four Blade Wing Oil Drilling Tools can enhance your drilling efficiency and borehole quality.

References

1. Johnson, A. R., & Smith, B. T. (2022). Advanced Drilling Technologies for Enhanced Borehole Quality. Journal of Petroleum Engineering, 45(3), 278-295.

2. Chen, X., & Wang, Y. (2021). Comparative Analysis of Multi-Blade Drilling Tools in Various Formations. International Journal of Oil, Gas and Coal Technology, 18(2), 156-172.

3. Peterson, M. K., & Davis, R. L. (2023). Hydraulic Optimization in Modern Drilling Tools: A Comprehensive Review. SPE Drilling & Completion, 38(1), 62-78.

4. Thompson, J. C., & Brown, E. S. (2022). Field Performance of Four-Wing Drilling Tools in Challenging Formations. Offshore Technology Conference Proceedings, OTC-25678-MS.

5. Liu, H., & Zhang, W. (2021). Advancements in PDC Bit Design for Improved Borehole Quality. Journal of Natural Gas Science and Engineering, 96, 104274.

6. Anderson, K. L., & Wilson, S. R. (2023). Economic Impact of Enhanced Drilling Technologies in Oil and Gas Exploration. Energy Economics, 118, 106318.