The choice between steel-body and matrix-body five-blade PDC drill bits affects drilling performance and operating expenses for procurement managers. Steel-body bits are appropriate for hard rock formations because of their impact resistance and structural integrity. Matrix-body variations assist cutters and last longer in abrasive situations. Understanding these basic distinctions helps procurement teams match bit selection to geological conditions, operational needs, and financial limits for best drilling efficiency.

Understanding Five Blades PDC Drill Bits and Their Body Types

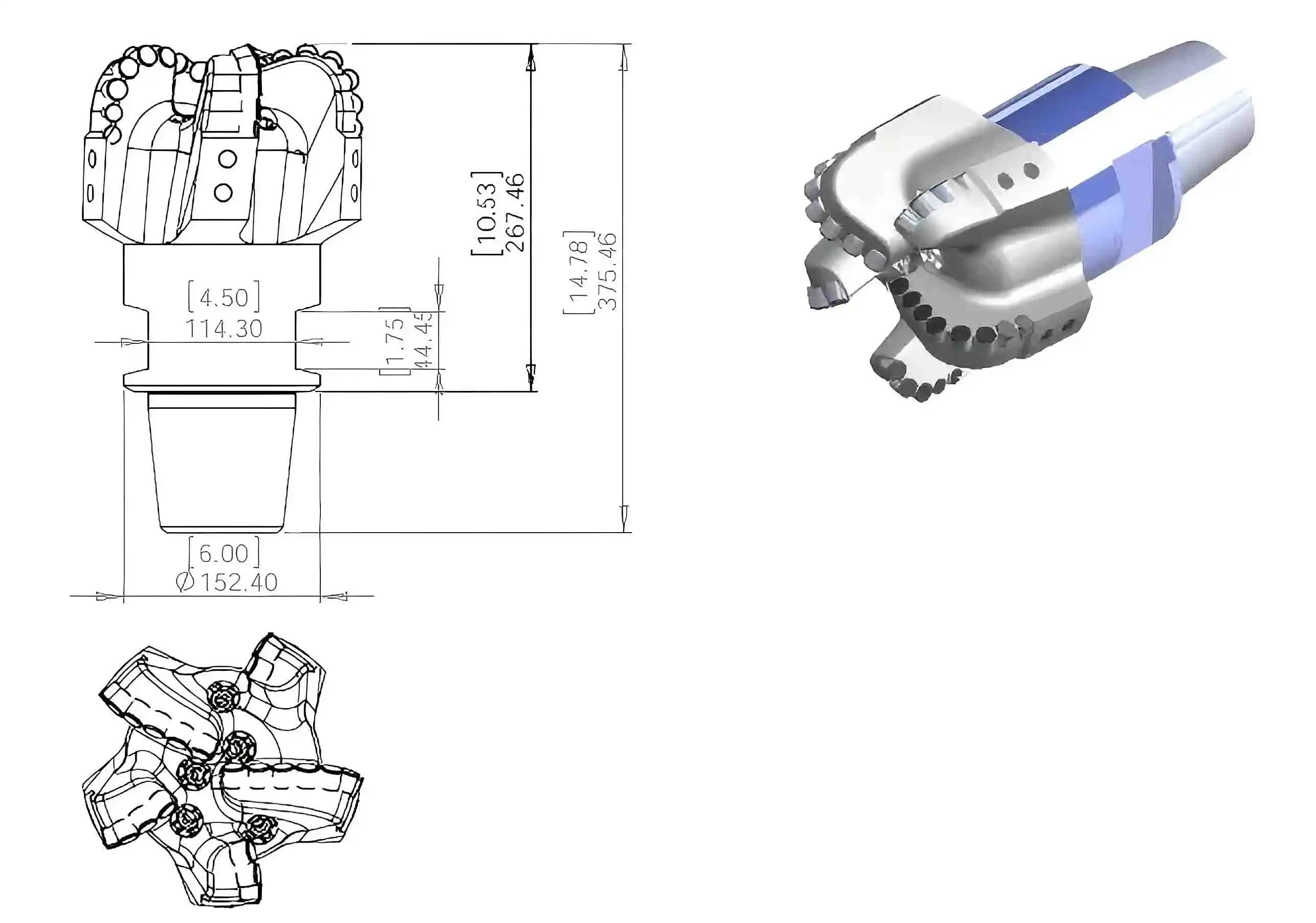

Five Blades PDC drill bits use modern cutting technology to drill efficiently in many geological formations. These specialist tools include five strategically placed polycrystalline diamond compact cutters for enhanced penetration and longevity. Steel-body or matrix-body construction affects drilling performance, operating costs, and maintenance, making this selection critical for procurement specialists.

What Are Five-Blade PDC Drill Bits?

PDC drill bits with five blades combine cutting-edge design with established drilling technology. The five-blade design balances weight and improves cutter placement, improving drilling stability and reducing vibration. These bits work well in medium-hard rocks, including shale, limestone, sandstone, and gypsum, throughout drilling applications.

These bits' rate of penetration (ROP), torque requirements, durability measures, and cost-effectiveness are key performance factors. Operating settings include 60-250 RPM, 10-100 KN drilling pressure, and 25-36 LPS flow. These requirements optimize performance and bit integrity throughout long drilling operations.

Overview of Steel-Body and Matrix-Body Drill Bits

Steel-body drill bits are made of high-strength alloy steel for impact resistance and endurance. For excellent hardness and toughness, precise machining and heat treatment are used. These building methods allow fast customization and cost-effective manufacture, making steel-body bits appealing for rapid deployment applications.

Matrix-body drill bits are made of tungsten carbide powder with metallic binders for better abrasion resistance. Powder metallurgy creates a solid, homogeneous framework that supports cutters and resists wear. Abrasive drilling settings have greater manufacturing costs, but longer tool life frequently compensates for the expense.

Technical Comparison: Steel-Body vs Matrix-Body Five-Blade PDC Drill Bits

Technical performance differences between steel-body and matrix-body five-blade PDC drill bit designsbenefit certain drilling applications. Steel-body bits withstand impact and mechanical stress, whereas matrix-body bits resist abrasion and retain cutters. Understanding these performance variations helps procurement teams tailor bit selection to operational and geological circumstances.

Structural Design and Durability

Steel-body bits are suited for tough drilling situations where bit stability is crucial due to their impact and mechanical shock resistance. The homogenous steel construction uniformly distributes stress across the bit body, preventing catastrophic failure under high-impact scenarios. This design method produces predictable wear patterns and consistent performance under diverse forming settings.

The matrix-body design's high-density tungsten carbide provides better cutter support. In silica or other abrasive mineral formations, the homogeneous matrix structure minimizes cutter pullout and improves abrasion resistance. The composite material maintains structural integrity and controls wear to ensure cutting efficiency throughout the bit's life.

Performance Efficiency and Drilling Speed

Steel-body bits can handle larger torque levels owing to their mechanical strength. This makes them suited for drilling operations with aggressive cutting settings or unexpected formation hardness fluctuations. The steel structure allows quick bit modification and repair.

Superior cutter retention and controlled wear make matrix-body bits more efficient in abrasive formations. Compared to steel-body alternatives, penetration rate is frequently more constant across long drilling intervals. However, enhanced cutting efficiency and cutter interaction with the formation may raise torque needs.

Maintenance and Lifespan Considerations

Field serviceability and repair choices are better for steel-body bits. Standard welding and machining can repair steel-body parts, lowering lifespan costs. Although longevity depends on formation circumstances, steel-body pieces usually degrade predictably.

Because of their composite nature, matrix-body bits need particular care, yet last longer in abrasive situations. While repair choices are limited, greater wear resistance frequently extends bit replacement intervals, decreasing drilling costs by reducing trip time and improving operating efficiency.

Procurement Insights and Decision-Making Criteria

Procurement selections must incorporate drilling circumstances, operating needs, and the total cost of ownership. Steel-body and matrix-body five-blade PDC drill bits have different benefits depending on the application. Understanding these aspects helps procurement managers choose bits for optimal ROI and reliable drilling.

When to Choose Steel-Body Five-Blade PDC Drill Bits

Steel bodies are ideal for impact-resistant and flexible forms. Steel structure increases mechanical strength and stress absorption for hard rock drilling. Due to their affordability and availability, steel-body bits are used for frequent bit swaps and quick deployment.

Steel-body bits are best for drilling in changeable formation conditions or mechanical stress. Steel construction's predictability and serviceability decrease operational risk and aid drilling program planning.

When Matrix-Body Five Blades PDC Drill Bits Are Preferred

In abrasive forms, when tool life is important, matrix-body bits perform better. Matrix structure improves durability and cutting performance in horizontal drilling and extended-reach wells. Superior cutter support prevents bit failure in difficult drilling settings.

Wear resistance and cutting efficiency make matrix-body bits ideal for shale deposits and other abrasive geological settings. Higher initial expense is generally mitigated by lower trip frequency and increased penetration during the drilling interval.

Pricing, Availability, and Supplier Considerations

Steel-body bits have cheaper initial costs, whereas matrix-body bits may give higher long-term value in some applications. Bulk purchase may save money, especially for big drilling projects with many comparable bits.

Steel-body bits have faster lead times owing to easier production. Steel structure is more flexible for custom applications and non-standard needs. Supplier dependability and technical support are vital when assessing long-term procurement agreements.

Real-World Application Scenarios and Case Studies

Examples of both construction types in various drilling applications show their performance and operational advantages. These case studies demonstrate the relevance of aligning bit selection to operational needs and assist procurement choices.

Case Study 1: Steel-Body Five-Blade PDC Drill Bits in Hard Rock Formation

In a hard limestone deposit with chert inclusions, a large oil service business had trouble drilling. Prior drilling efforts with ordinary PDC bits failed owing to collision and mechanical stress. To solve these operational issues, the procurement team chose steel-body five-blade PDC drill bits.

Implementation findings revealed 40% longer bit life than prior options and reliable drilling performance. The steel structure absorbed impact stresses while cutting efficiently. Reducing trip frequency and improving operational dependability cut drilling expenses by 25%, supporting the purchase choice.

Case Study 2: Matrix-Body Five-Blade PDC Drill Bits for Horizontal Drilling

An independent operator needed extended-reach drilling in abrasive, high-silica shale. Previous drilling with steel-body bits caused quick wear and frequent bit replacements, increasing costs and project timeframes. Engineering used matrix-body five-blade PDC drill bits for the horizontal portion.

The matrix-body bits outperformed expectations, lasting 30% longer before replacement. Drilling quality increased due to decreased vibration and uniform penetration. Appropriate bit selection saved money and time due to improved durability.

HNS Expertise in Five-Blade PDC Drill Bits Manufacturing

Since our 2013 inception in Xi'an, Shaanxi, Hainaisen Petroleum Technology Co., Ltd. has been a prominent producer of sophisticated drilling solutions. We specialize in steel-body and matrix-body five-blade PDC drill bits, using cutting-edge production and worldwide quality assurance techniques.

Our Expertise in Five Blades PDC Drill Bits

We have a 3,500 m² manufacturing facility with advanced equipment such as 5-axis machining centers, CNC machine tools, and automated welding lines. Our robust infrastructure lets us build steel-body and matrix-body combinations precisely and consistently. Custom bit design by our R&D team optimizes performance for individual geological conditions and operating needs.

Comprehensive testing techniques verify performance before shipping in quality assurance. We strictly follow international standards while continuously improving product dependability and customer satisfaction. Our comprehensive product offering covers oil and gas exploration, mining, and water well drilling.

Supporting Your Procurement and Operational Needs

Our technical support staff advises on bit selection, operating settings, and maintenance best practices to enhance drilling efficiency and tool life. Our various supply choices and global logistics enable prompt drilling tool deployment to project sites globally. Our client service emphasizes long-term technical excellence and trustworthy performance relationships.

Customization services let us adapt standard designs for specific applications or operations. Our technical team works directly with clients to optimize drilling solutions that are cost-effective and reliable.

Conclusion

Selecting steel-body or matrix-body five-blade PDC drill bits demands careful consideration of drilling circumstances, operational needs, and cost. In abrasive situations, matrix-body design improves durability and cutting efficiency, whereas steel-body construction improves impact resistance and cost-effectiveness for changeable formation circumstances. These basic distinctions help procurement professionals make educated choices that improve drilling performance and save operating expenses. Working with experienced manufacturers like HNS guarantees quality goods, technical competence, and dependable assistance throughout drilling operations.

Frequently Asked Questions

Q1: How do Five Blades PDC Drill Bits differ in performance between steel-body and matrix-body construction?

A: Steel-body bits offer superior impact resistance and mechanical strength, making them ideal for hard rock formations and variable drilling conditions. Matrix-body bits provide enhanced abrasion resistance and cutter support, resulting in longer tool life in abrasive formations like shale. The choice depends on specific geological conditions and operational requirements.

Q2: What factors should influence the choice between steel-body and matrix-body for drilling projects?

A: Key factors include formation abrasiveness, drilling trajectory (vertical vs. horizontal), expected drilling interval length, and total cost considerations. Steel-body bits work best in impact-prone environments, while matrix-body bits excel in abrasive conditions requiring extended tool life. Budget constraints and availability requirements also influence the selection process.

Q3: How can procurement teams ensure authentic and certified five-blade PDC drill bits?

A: Work with established manufacturers who provide comprehensive quality documentation, including material certifications and performance test results. Verify manufacturing facility credentials and quality management systems. Request detailed product specifications and ensure compliance with relevant industry standards. Establish long-term relationships with trusted suppliers who offer technical support and warranty programs.

Partner with HNS for Advanced Five-Blade PDC Drill Bits Solutions

HNS provides cutting-edge drilling solutions for your operations as a reputed five-blade PDC drill bit manufacturer. Our extensive product line comprises steel-body and matrix-body versions optimized for varied geological situations. We guarantee drilling operation quality and reliability with over a decade of manufacturing experience and superior production capabilities.

For optimal drilling productivity and lower operating costs, our technical staff offers tailored advice and bit selection help. HNS provides reasonable pricing, flexible delivery, and extensive technical support for standard and bespoke setups. Please email hainaisen@hnsdrillbit.com to discuss your needs and obtain a bulk quote.

References

1. Smith, J.R. (2022). "Advanced PDC Bit Design and Performance Analysis in Unconventional Formations." Journal of Petroleum Technology, Vol. 74, No. 8, pp. 45-52.

2. Anderson, M.K. & Thompson, L.W. (2021). "Comparative Study of Steel-Body versus Matrix-Body PDC Bits in Shale Gas Applications." SPE Drilling & Completion, Vol. 36, No. 3, pp. 234-248.

3. Chen, H.L. (2023). "Manufacturing Processes and Quality Control in PDC Drill Bit Production." International Journal of Rock Mechanics and Mining Sciences, Vol. 158, pp. 78-89.

4. Wilson, P.D. & Roberts, K.M. (2020). "Economic Analysis of Drill Bit Selection in Horizontal Drilling Operations." Energy Economics Review, Vol. 42, No. 6, pp. 156-167.

5. Martinez, C.A. (2022). "Performance Optimization of Multi-Blade PDC Bits through Advanced Cutter Placement Design." Rock Mechanics and Rock Engineering, Vol. 55, No. 4, pp. 1823-1836.

6. Taylor, R.S. & Davis, G.H. (2021). "Field Performance Comparison of Different PDC Bit Body Materials in Challenging Drilling Environments." Petroleum Engineering International, Vol. 29, No. 12, pp. 98-107.