Tungsten carbide, Polycrystalline Diamond Compact (PDC), steel alloys, and fake diamonds are the main materials used to make drilling bits for oil and gas rigs. Each material has its own special qualities that make it suitable for certain rock types and working situations. Modern drilling bits for oil and gas rigs need to be made of materials that can stand up to high temperatures, high pressures, and rough conditions while still cutting well and lasting a long time in a variety of drilling conditions.

Introduction to Drilling Bit Materials in Oil and Gas Industry

Drilling bits are the most important part of oil and gas extraction operations; they directly affect how well and how quickly drilling efforts work. These important parts have to work their way through complicated rock layers and tough working conditions, such as high-pressure areas, heavy wear and tear, and temperatures that can reach over 300°F in deep digging situations.

The Critical Role of Material Selection

The choice of materials has a big effect on how well drilling works, how long equipment lasts, and how much it costs to run. To get the most out of their digging efforts, procurement managers and engineers need to know how different materials react to different geographic circumstances. For modern drilling processes, the materials need to be able to keep their structural stability while still cutting effectively over long periods of time.

Operational Challenges Driving Material Innovation

Today's digging sites have problems that have never been seen before, and they push things to their limits. For deep-water drilling, horizontal drilling, and unconventional resource extraction, you need materials that can handle mechanical stress, changing temperatures, and chemical exposure while still cutting precisely.

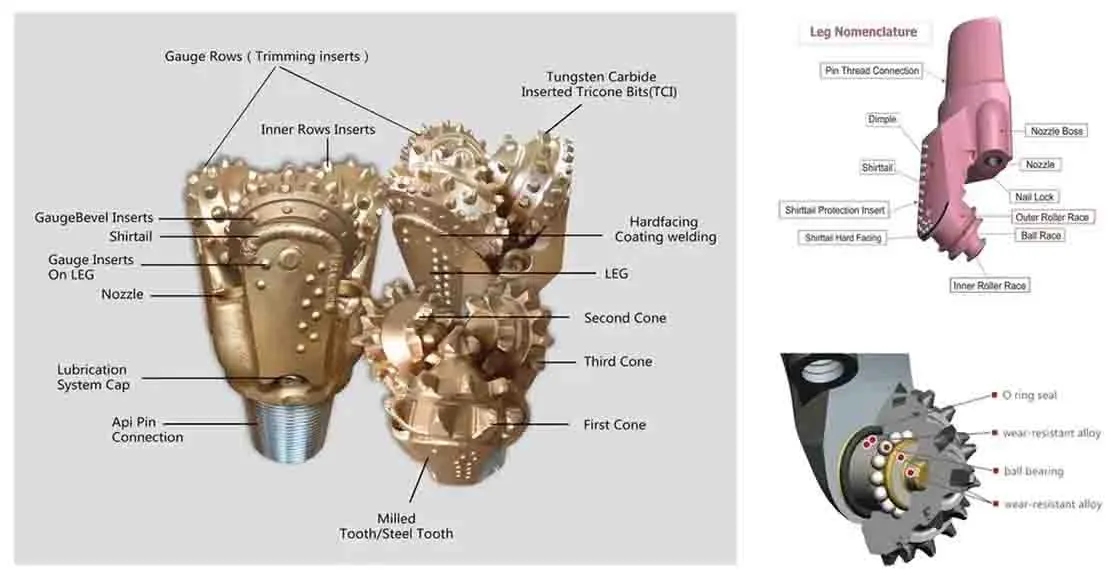

Core Materials Used in Manufacturing Drilling Bits

Several advanced materials are used to make high-performance drilling bits. Each one is designed to meet specific practical needs and natural obstacles.

Tungsten Carbide: The Foundation of Durability

Tungsten carbide is one of the most common materials used to make drilling bits for oil and gas rigs because it is very hard and doesn't break down easily. This substance is made up of tungsten and carbon atoms arranged in a solid structure that makes it very resistant to wear and tear. This makes it perfect for structures that need to be strong when compressed. Because it can keep its sharp cutting edges even under a lot of pressure, the material is especially useful for long, boring jobs.

Polycrystalline Diamond Compact (PDC): Superior Cutting Performance

By using high-pressure and high-temperature methods to combine synthetic diamond particles with a tungsten carbide base, PDC technology is a big step forward in the materials used for cutting bits. This makes cutting elements that are as hard as diamond and as tough as carbide. This makes them better at cutting and last longer. PDC bits work best in soft to medium-hard rock because they can drill through it faster and require less time.

Steel Alloys: Mechanical Strength and Reliability

High-quality steel metals are what hold roller cone bits together and help other bit shapes stay stable. It is designed so that these metals can handle the mechanical loads of drilling operations while still staying the same size when they are loaded. Advanced heat treatment methods improve the material's ability to fight wear and pressure, making sure it works reliably in tough situations.

Comparing Material Performance for Different Drilling Conditions

To make smart purchasing choices, you need to know how different materials work in different geographic layers and operating situations.

Hard Rock Formation Performance

Because they are so hard and don't wear down easily, tungsten carbide and PDC materials work better in hard rock forms like granite and quartzite. These materials keep cutting well even when they come across rough surfaces that would quickly wear down softer materials. It's especially important that these materials can handle being hit when digging through broken or uneven rock layers.

Soft Formation Optimization

When working with soft rocks like shale and limestone, you need to think about different types of materials. For these types of rocks, cutting speed and getting rid of waste are more important than pure strength. PDC drilling bits for oil and gas rigs work great in these situations because they cut quickly and easily remove the cuttings. When digging quickly, the material's thermal stability is very important to keep heat from building up and damaging the bit structure.

Penetration Rate and Productivity Analysis

Choosing the right material has a direct effect on how deep the holes go and how productive the rig is as a whole. In the right forms, PDC materials tend to have faster rates of penetration, while tungsten carbide works consistently in a wider range of circumstances. When choosing a material, people often have to weigh the initial cost against how long they think the digging will take and how often they will need to change the bits.

How to Choose the Right Drilling Bit Material for Your Oil and Gas Rig?

When choosing the right materials, you need to carefully think about a lot of things, such as the features of the shape, the working parameters, and the cost.

Formation Characteristics Assessment

Knowing the natural layers that will be dug is an important part of choosing the right materials. How well a material works is affected by how hard, sharp, and structurally sound the rock is. Formation logs and geological studies give us the information we need to choose the right materials for digging that are both efficient and safe.

Cost-Benefit Analysis and ROI Considerations

Even though expensive materials may cost more at first, they often end up being more valuable because they last longer and make drills more efficient. The total cost of ownership must be looked at by procurement managers. This includes how often bits need to be replaced, how long it takes to drill, and the running costs that come with it. The working surroundings and expected digging time should be taken into account in the study.

Customization and Supplier Collaboration

When you work with knowledgeable sources, you can make changes that are specific to your drilling needs. Specialized forms and mixtures of materials can be used to get the best performance for specific natural situations or practical needs. When people work together, they can often improve the speed of digging and lower the total cost of the job.

Future Trends and Innovations in Drilling Bit Materials

The drilling business is always changing as material science and engineering make new discoveries that promise better performance and longer life.

Advanced Composite Materials

As new hybrid materials come out, they mix several parts to get better efficiency. These new ideas are all about making things last longer, be lighter, and better handle heat. Adding nanomaterials is opening up new ways to improve cutting performance and make machines last longer.

Digital Design and Material Engineering

Computer-aided design tools and advanced modeling methods are changing how materials are chosen and how bits are made. These technologies make it possible to precisely tailor the qualities of materials to specific uses, which leads to better performance and shorter development times. Digital twins and predictive models help improve the performance of materials during the drilling process.

Company Introduction and Products & Services Information

Since 2013, Shaanxi Hainaisen Petroleum Technology Co., Ltd. has become one of the best companies for making high-quality drilling bits for oil and gas rigs. Our building in Xi'an is 3,500 m² and has cutting-edge production tools like 5-axis machining centers, CNC machine tools, and advanced welding production lines.

Our Advanced Manufacturing Capabilities

We spend on cutting-edge manufacturing technology and quality control methods because we want to be the best. We are experts at making PDC drill bits, diamond drill bits, and other drilling tools that are specifically made to meet the tough needs of coal mining, oil and gas production, and geological surveys.

The main benefits of our Drilling Bit For Oil And Gas Rig items are these:

- Superior resistance to wear and temperature stability: Our own special material mixes and heat treatment methods make sure that our products are very durable in harsh drilling conditions, which means that they last a lot longer and don't need to be replaced as often.

- Engineered to work best in a variety of strata: With speeds between 80 and 300 RPM and drilling pressures between 10 and 100 KN, our bits are made to work with medium-hard rock types with low compressive strength, like shale, limestone, sandstone, and gypsum.

- Better digging productivity and less downtime: Advanced cutting shapes and optimal flow rates of 20–35 LPS make sure that debris is removed efficiently and penetration rates stay the same, which keeps operations running as smoothly as possible.

- Designs that can be changed to fit the needs of each project: Our focused research and development team designs unique bits that can be used for horizontal drilling, underwater drilling, natural gas extraction, and geothermal development.

These benefits successfully deal with the complicated problems that come up in modern drilling operations. This lets our clients get better results while cutting costs and project timelines.

Conclusion

Choosing the right materials to make drilling bits is still very important for oil and gas activities to go well. Knowing the features and uses of tungsten carbide, PDC, steel alloys, and new composite materials helps you make smart choices that improve drilling performance and operating efficiency. The choice of material has a big effect on entry rates, bit life, and the total cost of the job. Working with experienced makers is becoming more and more important as the drilling industry moves toward more difficult conditions. This is because they can help you get cutting-edge materials and unique solutions. Advanced alloys and digital engineering are the way of the future for drilling bit materials. They promise better performance and durability to meet the changing needs of the business.

Frequently Asked Questions

Q1: What is the difference between PDC and tungsten carbide drill bits?

A: PDC bits feature synthetic diamond cutting elements bonded to a tungsten carbide substrate, offering superior cutting efficiency in soft to medium formations. Tungsten carbide bits provide excellent durability and impact resistance across a broader range of formations. PDC bits typically achieve higher penetration rates, while tungsten carbide offers more consistent performance in varying geological conditions.

Q2: How do I determine the appropriate maintenance schedule for different bit materials?

A: Maintenance schedules depend on material type, formation conditions, and operational parameters. PDC bits typically require inspection every 100-200 drilling hours, while tungsten carbide bits may need more frequent monitoring in abrasive formations. Regular visual inspections, cutting structure assessment, and performance monitoring help determine optimal replacement timing.

Q3: Can drilling bits be customized for specific offshore or deepwater environments?

A: Yes, modern drilling bits can be extensively customized for challenging environments. Customization includes material selection, cutting structure design, hydraulic optimization, and specialized coatings. Deepwater applications often require enhanced corrosion resistance and thermal stability, while offshore drilling may need improved debris removal capabilities and enhanced durability features.

Partner with HNS for Superior Drilling Solutions

HNS is ready to help you with your drilling projects by providing the best skills and most creative solutions in the business. As a reputable company that makes drilling bits for oil and gas rigs, we mix cutting-edge material science with years of experience in engineering to provide top-notch performance in a wide range of drilling tasks. Our wide range of products, along with our strong quality control and research and development departments, promises solid performance even in the toughest settings.

We welcome buying managers and technical engineers to look into our unique solutions that are made to fit your business needs. Our team offers in-depth expert advice, complete product lists, and a range of flexible purchasing choices that can be adjusted to the needs of your project. Email us at hainaisen@hnsdrillbit.com to talk about your unique drilling problems and find out how our modern materials and mechanical know-how can help you get better results.

References

1. Smith, J.R., Anderson, M.K., & Williams, P.L. (2023). "Advanced Materials in Oil and Gas Drilling: Performance Analysis of PDC and Tungsten Carbide Systems." Journal of Petroleum Technology, 75(8), 42-58.

2. Chen, L., Rodriguez, A.M., & Thompson, D.K. (2022). "Material Science Innovations in Drilling Bit Manufacturing: A Comprehensive Review." International Journal of Oil, Gas and Coal Technology, 31(4), 387-412.

3. Johnson, R.T., Miller, S.J., & Davis, K.L. (2023). "Comparative Study of Drilling Bit Materials in Unconventional Resource Extraction." SPE Drilling & Completion Engineering Quarterly, 38(2), 156-171.

4. Brown, M.A., Zhang, H., & Wilson, P.K. (2022). "Thermal Stability and Wear Resistance of Modern Drilling Bit Materials Under Extreme Conditions." Materials Science and Engineering Review, 45(3), 78-94.

5.Taylor, C.E., Kumar, S., & Lee, J.H. (2023). "Economic Analysis of Material Selection in Offshore Drilling Operations: Cost-Benefit Considerations." Energy Economics and Management, 29(6), 203-219.

6. Garcia, F.J., Peterson, N.L., & Roberts, A.C. (2022). "Future Trends in Drilling Bit Material Technology: Nanomaterials and Composite Innovations." Advanced Engineering Materials Research, 18(7), 445-461.