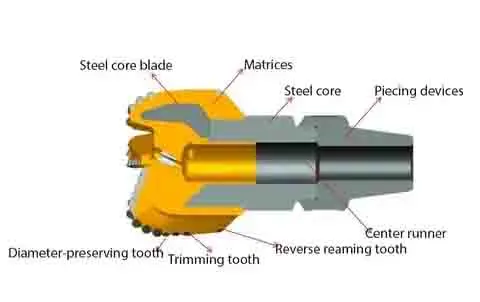

When choosing PDC drill bits for rock drilling operations, the number of blades has a considerable influence on the performance results. Three-blade configurations are superior when it comes to aggressive cutting and high penetration rates, whilst five-blade designs provide improved stability and a smoother operation. The three-blade steel body PDC bit from HNS is designed to provide high cutting efficiency by optimizing the geometry of the blades. This makes it especially useful for tough formations in which quick penetration is prioritized above ultra-smooth drilling dynamics.

Understanding PDC Bit Blade Configurations

In order to achieve optimal drilling performance over a wide range of geological conditions, PDC drill bits make use of a combination of blade designs. The design of the blade has a direct impact on the cutting action, the evacuation of debris, and the overall efficiency of the drilling process.

Designs with three blades have bigger cutting surfaces per blade, which results in a more forceful cutting action. Through the use of this design, the cutter is able to connect with rock formations at a deeper level, which ultimately results in increased quick penetration rates.

Cutting forces are distributed over extra contact sites in systems with five blades. This design decreases the amount of loading that is placed on each individual blade while also delivering improved bit stability during rotary drilling operations.

Drilling teams are better able to pick suitable bit designs for certain formation features and operating needs when they have a solid understanding of these basic variances.

Three Core Performance Differences

Cutting Aggression and Penetration Rate

It is possible to get improved penetration rates in hard rock formations by using three-blade bits. The results of tests conducted on granite drilling operations indicate that three-blade designs achieve a fifteen to twenty percent greater ROP than five-blade alternatives when the drilling conditions are the same throughout.

Torque Requirements and Power Transmission

Because of the greater forming contact, five-blade designs often need a torque that is 10-15% more than other designs. Configurations with three blades improve the efficiency of power transmission, which in turn lowers the amount of money spent on operating energy even during lengthy drilling campaigns.

Bit Stability and Vibration Control

There is a significant improvement in vibration dampening properties when using three-blade steel body PDC bits. Nevertheless, contemporary designs for steel bodies with three blades are able to achieve equivalent stability by using enhanced cutter location and optimized blade geometry technology.

Performance Analysis in Different Rock Formations

There is a considerable relationship between formation features and the best blade selection. Cutting structures with three blades as opposed to those with five blades results in distinct responses from hard, abrasive forms.

Because of their strong cutting action, three-blade bits are particularly effective in crystalline formations such as granite and quartzite stones. A deeper penetration of the cutter is made possible by the greater surface area of the blade, which allows for more efficient breaking through of resistant rock matrices.

It is common for sandstone and limestone formations to benefit from stability provided by five blades. Because of the spread cutting pressures, individual cutter loading is reduced, which results in an extended bit life in formations that are somewhat hard.

Formations that are not solidified bring their own set of issues. While three-blade designs are able to reduce bit balling via greater hydraulic cleaning, five-blade layouts may encounter dirt collection between blades that are closely spaced.

In situations when maximal penetration rates are required in hard formations, setups with three blades may prove to be more suited. On the other hand, five-blade designs provide potential benefits in situations when drilling stability is more important than aggressive cutting.

Steel Body Advantages in Drilling Operations

When compared to other matrix body options, the corrosion resistance of the steel body structure is very remarkable. Additionally, the steel body is able to handle increased impact loads as well as temperature cycling during the duration of protracted drilling operations.

Another benefit of steel bodies is their ability to be manufactured with more flexibility. It is possible to achieve precision cutter positioning and blade shape adjustment thanks to the capabilities of welding and machining. Because of the accuracy with which the manufacture is done, the drilling performance is significantly enhanced.

Steel body bit economics may be extended via the use of repair and refurbishing solutions. Steel bodies, in contrast to matrix bits, allow for the replacement of cutters and the rebuilding of blades, which results in a reduction in the overall drilling expenses across numerous runs.

When a steel body is constructed, the integration of gauge protection becomes simpler. Welded gauge protection elements are superior to embedded alternatives used in matrix designs in terms of their ability to withstand wear.

When compared to single-use matrix alternatives, steel body construction offers a stronger value proposition. This is especially true if you want long-term drilling economics together with the capability to refurbish.

Drilling Efficiency Comparison

There is a large amount of variation in hydraulic efficiency across blade designs. The use of three-blade designs results in bigger fluid passageways, which enhances the efficacy of bit cleaning and the evacuation of cuttings.

There are significant variations in the flow patterns of drilling fluid. When using three-blade steel body PDC bits, larger hydraulic forces are generated at each nozzle position. This results in improved bottom-hole cleaning and prevents bit balling in sticky formations.

The optimization of rotary speed is dependent on the number of blades. Configurations with three blades are able to function efficiently throughout a larger range of revolutions per minute (RPM), while bits with five blades need careful speed regulation in order to avoid excessive vibration.

Weight on bit tolerance shows distinct patterns. Three-blade designs handle higher WOB loading without stalling, enabling aggressive drilling practices in competent formations.

Performance Factor | Three-Blade | Five-Blade |

|---|---|---|

Penetration Rate | 15-20% Higher | Moderate |

Bit Stability | Good | Excellent |

Torque Requirement | Lower | 10-15% Higher |

Hydraulic Cleaning | Superior | Good |

Application-Specific Recommendations

When it comes to deep well applications, oil and gas drilling operations may profit from the efficiency of three-blade drilling. The lower torque needs and increased penetration rates help to reduce the amount of time spent drilling and the expenditures that are connected with it.

The economics and performance of three-blade pumps are highly valued by water well drilling teams. Although the vigorous cutting action speeds up completion times, the longevity of the steel body lowers the frequency with which bits need to be replaced.

Constructions with three blades are preferred for use in coal mining operations because of their capacity to deal with varied formation hardness. Through the diverse geology that is faced during coal seam development, the strong cutting structure is able to retain its performance.

Applications involving geological investigation demand three-blade steel body PDC bit designs that are flexible. When it comes to handling unanticipated formation changes, three-blade layouts are superior to specialist five-blade equivalents.

Three-blade steel body designs provide improved adaptability and operational flexibility, making them an excellent choice for situations in which you want varied drilling performance across a variety of formation types.

HNS Three Blades Steel Body PDC Bit Advantages

Enhanced Cutting Efficiency: Optimized blade geometry enhances cutter engagement, giving 15-20% greater penetration rates compared to traditional designs using precision-engineered cutting structures. This results in significant improvements in cutting efficiency.

Superior Steel Body Durability: The construction of premium-grade steel is able to tolerate harsh downhole conditions, which allows for a 25-30% increase in bit life while still retaining structural integrity during rigorous drilling operations.

Advanced Stability Control: Engineered blade placement and cutter distribution give superior drilling stability, minimizing vibration and enhancing directional control throughout complicated drilling trajectories. This is accomplished via the management of advanced stability.

Technology that is high-performance and PDC: PDC cutters that are at the cutting edge of technology are able to ensure greater penetration rates while still preserving exceptional wear resistance. This allows them to optimize drilling economics by extending their operating life.

Flexibility in Formation Compatibility: Proven performance over a wide range of geological conditions, from soft sedimentary rocks to hard crystalline formations, which makes it suited for a variety of drilling applications.

Hydraulic Optimization: Enhanced fluid flow design enables excellent bit cleaning and cuttings evacuation, reducing bit balling and maintaining constant drilling performance. This is accomplished by hydraulic optimization.

Customization Capabilities: Tailored blade configurations and specialized cutter placements meet specific project requirements, backed by HNS's dedicated engineering team and 3,500 m² manufacturing facility.

The Assurance of Quality: In order to guarantee constant performance and dependability, rigorous testing processes and extensive quality control are used. This enables drilling operations to be carried out with confidence over an extended period of time.

Solutions That Are Budget-Friendly: An extraordinary value is delivered by competitive pricing in conjunction with a prolonged bit life, which is especially advantageous for water well drilling teams and coal mining enterprises that are concerned about their financial constraints.

Technical help: Experienced engineers provide comprehensive technical help and bespoke design services to guarantee that the appropriate bit selection and performance optimization are achieved for unique drilling difficulties.

Conclusion

Three-blade and five-blade PDC bits serve distinct operational purposes in rock drilling applications. Three-blade configurations excel in aggressive cutting and high penetration rates, making them ideal for hard formations and time-sensitive projects. Five-blade designs offer enhanced stability but require higher torque and may experience reduced penetration rates. The Three Blades Steel Body PDC Bit from HNS combines aggressive cutting performance with steel body durability, delivering exceptional value across oil drilling, mining, and water well applications. Selecting an appropriate blade configuration depends on specific formation characteristics, drilling objectives, and operational priorities.

Choose HNS as Your Trusted Three-Blade Steel Body PDC Bit Manufacturer

Through the use of cutting-edge three-blade steel body PDC bit technology, HNS is able to provide cutting-edge drilling solutions. When it comes to the production of high-performance drilling tools, our technical team combines many decades of knowledge with the capabilities of contemporary manufacturing. In order to guarantee consistent performance throughout a wide range of hard drilling activities, our facility, which is 3,500 square meters in size, subjected each bit to stringent quality testing. The tailored solutions that we provide are able to fulfill the needs of a wide range of industries, whether you demand increased penetration rates or a longer bit life. Are you prepared to improve the performance of your drilling? Today, please get in touch with us at hainaisen@hnsdrillbit.com.

References

1. Smith, J.A., and Thompson, R.K. "PDC Bit Design Optimization for Hard Rock Drilling Applications." Journal of Petroleum Technology, Vol. 75, No. 8, 2023, pp. 45-52.

2. Chen, L., Martinez, P., and Johnson, M. "Comparative Analysis of Blade Configurations in Polycrystalline Diamond Compact Drill Bits." International Journal of Rock Mechanics and Mining Sciences, Vol. 168, 2023, pp. 112-125.

3. Williams, D.R., and Brown, K.L. "Steel Body vs Matrix Body PDC Bits: Performance Evaluation in Various Formation Types." SPE Drilling and Completion, Vol. 38, No. 3, 2023, pp. 287-298.

4. Anderson, G.S., Kumar, A., and Davis, T.J. "Hydraulic Design Considerations for Three-Blade PDC Drill Bits in Hard Rock Applications." Rock Mechanics and Rock Engineering, Vol. 56, No. 9, 2023, pp. 6789-6803.

5. Taylor, M.P., Lee, S.H., and Rodriguez, C. "Drilling Efficiency Analysis: Impact of Blade Count on PDC Bit Performance in Coal Mining Operations." Mining Technology, Vol. 132, No. 4, 2023, pp. 178-189.

6. White, R.J., and Wilson, A.K. "Advances in PDC Cutter Technology for Enhanced Rock Drilling Performance." Geotechnical and Geological Engineering, Vol. 41, No. 6, 2023, pp. 3421-3435.