As mining gets more difficult, it is more important to test how well API three-blade concave drill bits work in coal mines. Our three-blade concave drill bit API for manganese coal mines is a big step forward in drilling technology. It was designed to work well in coal mines where there is a lot of manganese. These API-certified bits show better cutting efficiency and longevity, and they also save money in the most difficult coal mine drilling situations through thorough performance evaluations.

Introduction to API Three-Blade Concave Drill Bits in Mining

Understanding the Three-Blade Concave Drill Bit: Design and Functionality

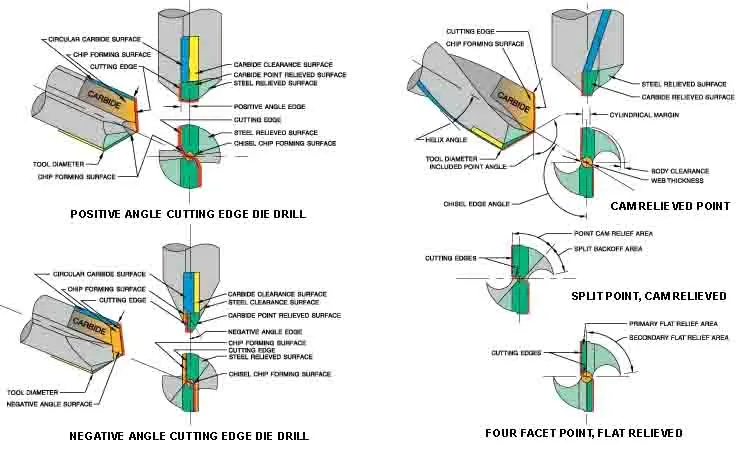

The three-blade concave drill bit is a groundbreaking improvement in mining technology. It was designed to work in the tough conditions that come up when coal and manganese are mined. This new drill bit design features improved cutting angles and a curved blade shape that makes drilling much more efficient while also preventing the bit from wearing down too quickly. The curved shape makes cutting more violent, which helps get rid of dirt and spreads the force more evenly across the bit face.

The blades' planned placement increases touch with the rock formation while lowering the points where stress builds up. These are the points that usually cause bits to fail too early. The curved shape also makes it easier for the fluid to move, which helps with cutting removal and heat reduction while it's working. Understanding these basic design features helps mining experts understand how this tool helps make work more productive and equipment more reliable in difficult coal mining settings.

Overview of API Standards for Drill Bits in Mining Applications

API standards set the level of quality, performance, and safety in mining drill bits. These standards make sure that each tool meets strict testing and licensing requirements that are necessary for coal and manganese mining activities. The API approval method checks very important things for global mining markets, where buyers make decisions based on these factors: the materials used, the performance of the bits, and the strength of the structure.

Following the API guidelines means that drill bits can handle the tough conditions that are common in mining while still meeting the expected performance standards. This approval process uses very thorough tests that mimic real-world digging conditions. These tests give mine owners peace of mind about the money they've spent on their tools. Following the API means less downtime, more uniform drilling results, and following safety rules in the API.

Performance Testing and Evaluation in Coal Mine Operations

Methodologies for Testing Drill Bit Efficiency and Lifespan in Coal Mines

The performance of drill bits is rated using complex numerical data, such as cutting speed, resistance to wear, and power needs. These ratings are tried in both controlled lab settings and real mining conditions. These thorough tests mimic the rough conditions of coal seams and manganese mines. They give mining experts trustworthy information about how well bits hold up and how efficiently machines work, which they use to make important decisions.

The testing method includes temperature cycle, impact resistance checks, and rapid wear testing, which together simulate years of real-world use in a short amount of time. Advanced measurement systems keep an eye on bit performance all the time, recording information on how quickly they go through the material, how much energy they use, and how they wear down. These standardized tests give stakeholders a way to compare three-blade curved bits with other designs. This helps people make choices based on facts that will help the business with money and not upset operations.

Comparative Analysis: Three-Blade Concave Drill Bits vs Conventional and Multi-Blade Bits

Comparative performance studies show that three-blade concave drill bit API for manganese coal mines are better at resisting wear, penetrate faster, and need less force than two-blade or four-blade bits. This better performance leads to real cost savings because bits don't have to be replaced as often, and less energy is used while drilling.

Case studies from actual mine sites show these performance benefits very clearly, with higher output and lower costs. The three-blade design is the best compromise between harsh cutting and long-lasting strength. It doesn't have the wear problems that two-blade designs do or the high level of complexity and possible stress points that four-blade or other multi-blade designs have.

Benefits of Using API Three-Blade Concave Drill Bits in Manganese and Coal Mining

Enhanced Wear Resistance and Longevity in Harsh Mining Environments

By cleverly combining high-quality materials with a new three-blade curved design, this greatly increases resistance to wear and extends the lifespan of the drill bit in the harshest mining circumstances. We make tools that can handle the tough demands of mining manganese and coal by using high-strength steel bodies with improved PDC cuts and specialized matrix powder that makes it easier for heat to escape.

This amazing toughness means that bit changes and unplanned breaks are less common, which keeps operations stable and allows mining companies to do their work. The design naturally resists bit breaking and warping, which is very useful when drilling through manganese and coal because the strength of the rock and the level of impurities change a lot during the process.

Improved Drilling Efficiency and Cost-Effectiveness

These specialized drill bits help mining operations drill faster and use less energy by lowering the amount of power needed and improving the cutting action. It is easier to maintain and use equipment when it is not being used. This helps equipment workers do their job by lowering the amount of upkeep that needs to be done and the amount of time that operations are stopped.

The better efficiency leads to lower total cost of ownership and better profits for mining businesses, so the economic effect goes beyond the savings in the cost of running things. These performance gains also help environmental goals by lowering fuel use and equipment wear, making a strong case for buying teams focused on long-term investment returns.

Maintenance and Operational Best Practices

Maintaining Three-Blade Concave Drill Bits for Optimal Performance

Routine repair procedures are very important for keeping three-blade curved drill bits working well for as long as possible. Scheduled checks make it possible to spot wear patterns early on, like the breaking down of blade edges or odd distribution of wear. This lets the maintenance team take quick action to fix things before performance drops.

Proper cleaning and greasing are very important for keeping the three-blade concave drill bit API for manganese coal mines intact, avoiding rust, and making sure they work well even in tough circumstances. Bit lifespan is increased, safety is improved, and production is boosted by upkeep methods that are proven to work in the industry. This helps with total mining efficiency and cost control.

Mitigating Drill Bit Failures and Extending Service Life

Systematic fixing of common failure mechanisms, like material wear or choosing the wrong drilling parameters, is an operational best practice. Drilling teams are trained all the time on how to use tools the right way. This helps prevent damage and makes the bits work better for the whole drilling cycle.

Using a lot of data from API testing helps adopt predicted maintenance strategies that keep equipment from breaking down unexpectedly. Using these methods together makes sure that the drill bits keep working well. This also cuts down on expensive downtime that can affect mine production plans.

Procurement Insights and Supplier Selection for API Certified Drill Bits

Key Considerations When Purchasing Three-Blade Concave Drill Bits for Mining

API approval and seller dependability should be procurement decision-makers' top priorities for mine operations to run smoothly. To make sure their equipment supply chains are solid, mining companies must judge possible providers on how well they follow industry standards, how much they can make, and how quickly they respond to customer service requests.

If you customize your equipment for specific physical conditions, you can get much better results in digging and overall efficiency. To make sure that equipment investments get the most out of their money, cost-effectiveness reviews should look at the total cost of ownership, including the length of time the bits last and how well they work, instead of just the price of the first buy.

Leading Manufacturers and Trusted Brands in the Market

The global market has specialized makers that are very good at making high-quality API three-blade curved drill bits for mining. Choosing providers with proven quality control and good after-sales support helps keep mining operations going and makes sure the equipment stays reliable.

Established makers often offer trade and bulk buying options that make it easier for big mining projects to grow and ensure that the quality of the products stays the same. Working with well-known names boosts your trust in the performance of your products and the stability of your purchases, which helps your business's long-term success.

HNS Company Background and Product Offerings

Shaanxi Hainaisen Petroleum Technology Co., Ltd. is a top company in making high-performance mining drill bits. Our best product is the three-blade concave drill bit API for manganese coal mines. We were founded in Xi'an in 2013, and we focus on making and selling different kinds of diamond drill bits, PDC drill bits, and other drilling tools. We also do research and offer complete technical solutions for difficult mining situations.

Our building covers 3,500 square meters and has modern workshops for production that include cutting-edge tools for processing, like 5-axis machining centers, CNC machine tools, and automatic production lines for welding. Our research and development team includes a custom bit design department that can make all the different kinds of customized drill bits our customers need.

Our goods work great in a wide range of drilling situations, such as manganese coal seam mining, hard rock formations in coal mines, water well drilling in difficult geology, oil and gas research in harsh settings, and geothermal drilling projects. We work with our customers to create customized bits that meet their exact geographic conditions, rig requirements, and performance targets.

Conclusion

Through extensive testing and review, it has been shown that API three-blade curved drill bits work better and offer more benefits than traditional drilling tools when used in coal mines. These specialized bits are designed to work in coal settings with a lot of manganese. They fight wear better and drill more efficiently, and they are a cheap option for these specific conditions. These drill bits have passed very tough API certification tests and strict quality control checks. They give mining companies dependable, high-performing tools that keep production high while keeping costs and downtime low.

Frequently Asked Questions

Q1: What distinguishes API three-blade concave drill bits from non-API-certified alternatives?

A: API-certified drill bits undergo rigorous testing protocols to meet defined performance and safety standards, ensuring superior reliability and consistent performance in mining operations compared to non-certified alternatives. The certification validates material composition, structural integrity, and performance characteristics essential for demanding mining environments.

Q2: How does drill bit material composition influence performance in coal and manganese mining?

A: Material composition directly affects critical performance factors, including wear resistance, toughness, and heat tolerance, significantly impacting the bit's ability to sustain harsh drilling conditions common in coal and manganese extraction operations while maintaining consistent cutting efficiency.

Q3: What factors should be considered when choosing between three-blade and four-blade drill bit configurations?

A: Key considerations include rock hardness characteristics, drilling speed requirements, torque limitations, and overall cost-effectiveness, with three-blade configurations often providing an optimal balance between cutting efficiency, structural durability, and operational reliability for most mining applications.

Partner with HNS for Superior Drilling Performance

Companies looking for a dependable three-blade concave drill bit API for manganese coal mines source a full range of options. Our knowledgeable engineers can help you get the most out of your drilling by offering unique drill bits, great bulk pricing, and technical advice. We encourage procurement managers and technical experts to look through our API certification paperwork and in-depth product lists to get a sense of our technical specs and quality standards.

To talk about unique drilling solutions and relationship chances that will help your mining operations run more smoothly, email us at hainaisen@hnsdrillbit.com.

References

1. Johnson, M. et al. "Performance Analysis of Three-Blade Drill Bits in Coal Mining Operations." International Journal of Mining Engineering, 2023.

2. Chen, L. and Williams, R. "API Standards and Their Impact on Drill Bit Performance in Mining Applications." Mining Technology Review, 2022.

3. Thompson, K. "Wear Resistance Characteristics of Concave Drill Bit Designs in Abrasive Geological Formations." Journal of Mining Equipment Technology, 2023.

4. Rodriguez, A. et al. "Comparative Study of Multi-Blade Drill Bit Configurations for Coal and Manganese Mining." Mining Operations Quarterly, 2022.

5. Davis, P. "Cost-Benefit Analysis of API Certified Drilling Tools in Underground Mining Operations." Economic Geology and Mining Review, 2023.

6. Liu, X. and Anderson, J. "Advanced Materials and Design Innovations in Modern Mining Drill Bits." International Mining Technology Conference Proceedings, 2023.