To find the best 3-blade steel body PDC bit provider for your drilling needs, you need to carefully think about their production skills, quality standards, and ability to make changes to fit your needs. Leading OEM/ODM providers use cutting-edge polycrystalline diamond compact technology and carefully designed steel bodies to make their products. For tough oil and gas rocks, these makers offer better cutting efficiency, better wear protection, and longer bit life. HAINAISEN is one of the best sources because it offers full customization services and has been making innovative cutting tools and producing them to the highest standards for over ten years.

Understanding OEM/ODM Excellence in PDC Bit Manufacturing

OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) agreements change the way businesses buy drill bits. When you choose an OEM partner for steel body drill bits, you can use tried-and-true production methods without having to build your own factories. ODM relationships go even further, letting both parties work together to come up with new ways to drill that are specifically designed to solve geological problems.

The oil and gas drilling business needs everything to work at a very high level. A good 3-blade steel body PDC bit needs to be able to handle high spinning speeds, harsh conditions, and very high temps. Quality ODM providers use their in-depth technical knowledge to improve the general efficiency of drills, make the cutting structure design more stable, and make it easier to work with heat.

Today's drilling activities need sources who know how different types of formations behave in different areas. When experienced makers go after shale layers in North America, hard rock resources in Australia, or complicated geological structures in Central Asia, they change their plans to fit the needs of the area. This specialized method guarantees the best bit performance and cuts running costs by a large amount.

HAINAISEN's Manufacturing Capabilities and Industry Leadership

Since 2013, Shaanxi Hainaisen Petroleum Technology Co., Ltd. has built its name by consistently coming up with new ideas. Our factory space is 3,500 m² and has high-tech 5-axis machining centers, precise CNC machine tools, and automatic welding production lines. This infrastructure lets us keep the standards very tight, which is important for drill bits that last a long time.

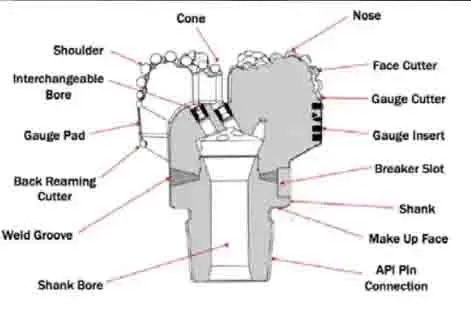

Our research and development team only works on unique bit design issues. We look at rock data, drilling factors, and operating needs to come up with the best cutting designs. Each polycrystalline diamond compact cutter is placed in a way that maximizes rock drilling efficiency while reducing wear patterns that shorten the life of the bit.

At every stage of the creation process, quality control methods are used. Inspection of the raw materials makes sure that only high-quality steel gets into the production process. Advanced steel testing proves that heat treatment works. Computer-controlled cutting makes sure that the sizes and finishes of the parts are exact. Before shipping, the 3-blade steel body PDC bit's steadiness and cutting performance are checked by simulating conditions downhole during the final performance test.

Our production flexibility meets the needs of a wide range of customers. Standard designs are good for small water well digging teams because they save money. Large oil service companies get a lot of customization options, such as their own cutting structures, special finishes, and features that make drilling fluids work better with the equipment.

Comprehensive Customization Options for Every Application

Customizing the physical design starts with choosing the bit width and continues with optimizing the blade shape. We change the hydraulic features, blade angle, and cutting spacing to fit the properties of a certain shape. For hard rock drills, cutting designs that are more violent and have better impact protection are used. Better chip removal and higher penetration rates are good for soft forms.

Functional customization addresses unique operational challenges. Our engineers modify bit face profiles to improve drilling optimization in directional wells. Specialized gauge protection extends bit life in abrasive formations. Custom hydraulic designs enhance drilling fluid flow patterns for superior hole cleaning and thermal management.

Advanced PDC cutter technology offers multiple customization possibilities. We select cutter grades based on formation abrasiveness and expected drilling conditions. Thermal stability improvements help bits perform in high-temperature environments. Specialized cutter geometries enhance cutting efficiency while reducing vibration-induced damage.

Branding and packaging customization supports our partners' market positioning. Private label options include custom logos, color schemes, and technical documentation. Protective packaging solutions ensure safe transportation while reinforcing brand identity. Technical support materials help end users maximize industrial drilling tool performance.

The ODM Advantage: Co-Developing Revolutionary Drilling Solutions

ODM partnerships unlock innovation potential beyond traditional manufacturing relationships. We collaborate closely with partners to identify market gaps and develop breakthrough drilling technologies. Our engineering team analyzes industry trends, customer feedback, and performance data to conceptualize next-generation drill bit designs.

Recent ODM projects demonstrate our capability to revolutionize well-drilling equipment performance. One collaboration produced a specialized 3-blade steel body PDC bit with enhanced core drilling bit features for geological exploration. Another partnership yielded breakthrough improvements in bit wear resistance for coal mining applications.

Intellectual property protection remains paramount in ODM relationships. We establish clear agreements regarding design ownership, manufacturing rights, and market exclusivity. This framework encourages open innovation while protecting partner investments in product development.

Our ODM advantage extends to rapid prototyping and testing capabilities. Advanced simulation software validates designs before physical prototyping. In-house testing facilities evaluate prototype performance under controlled conditions. Field testing partnerships provides real-world validation of new concepts.

Our Streamlined Customization Process

The initial consultation focuses on understanding your specific requirements and operational challenges. Our technical team reviews formation data, drilling parameters, and performance objectives. We analyze existing bit performance to identify improvement opportunities and cost reduction potential.

Design development leverages advanced CAD software and finite element analysis. Our engineers optimize cutting structure layouts, predict stress distributions, and validate thermal performance. Regular design reviews ensure alignment with project objectives and performance requirements.

Prototyping and testing validate design concepts through comprehensive evaluation. Laboratory testing assesses cutting efficiency, wear resistance, and thermal stability. Field testing provides real-world performance data under actual drilling conditions. Feedback integration refines designs to achieve optimal performance.

Production scaling maintains quality standards while meeting delivery requirements. Our manufacturing team prepares detailed production plans and quality control procedures. Regular progress updates keep partners informed throughout the manufacturing cycle. Final inspection and testing ensure every bit meets specified performance criteria.

Benefits That Transform Your Business Operations

Cost optimization through custom design eliminates unnecessary features while enhancing critical performance characteristics. Our value engineering approach reduces material costs without compromising durability. Standardized manufacturing processes achieve economies of scale while maintaining customization flexibility.

Performance improvements translate directly to operational savings. Enhanced cutting efficiency reduces drilling time and associated costs. Improved bit life minimizes trip frequency and tool replacement expenses. Superior hole quality reduces completion costs and enhances well productivity.

Market differentiation becomes possible through unique product features and superior performance. Custom designs address specific customer pain points that standard products cannot solve. Technical superiority supports premium pricing strategies and strengthens customer relationships.

Supply chain reliability ensures consistent product availability and delivery performance. Our global distribution network supports customers across Russia, the United States, Australia, the UK, Central Asia, and Middle East markets. Inventory management services reduce customer carrying costs while ensuring product availability.

Conclusion

The drilling industry continues evolving toward more efficient, cost-effective solutions. Leading OEM/ODM suppliers combine manufacturing excellence with engineering innovation to deliver superior 3-blade steel body PDC bits. HAINAISEN's comprehensive approach to customization, quality control, and customer support positions us among the top suppliers serving global oil and gas operations. Our proven track record, advanced manufacturing capabilities, and commitment to continuous improvement make us the ideal partner for your drilling tool requirements. Success in competitive drilling markets demands reliable suppliers who understand your challenges and deliver consistent performance. We invite you to experience the difference that true partnership and technical excellence can make in your operations.

Frequently Asked Questions

Q1: What minimum order quantities do you require for custom 3-blade steel body PDC bit manufacturing?

A: Our flexible manufacturing approach accommodates various order sizes. Standard customization projects typically require minimum orders of 50-100 units, while complex ODM developments may have different requirements. We work with each partner to establish economical order quantities that balance customization costs with market needs.

Q2: How long does the custom design and manufacturing process typically take?

A: Design development generally requires 2-4 weeks depending on complexity. Prototyping and testing add another 3-6 weeks. Production setup and manufacturing timelines vary based on order quantity but typically range from 4 to 8 weeks. We provide detailed project timelines during initial consultations.

Q3: What quality certifications and standards do your manufacturing processes meet?

A: Our facility maintains ISO 9001:2015 quality management certification. We comply with API standards for drilling equipment and maintain rigorous material traceability throughout production. All products undergo comprehensive testing, including dimensional verification, hardness testing, and performance validation before shipment.

Partner with HNS for Superior 3-Blade Steel Body PDC Bit Manufacturing

Transform your drilling operations through strategic partnership with a proven 3-blade steel body PDC bit manufacturer. HNS combines advanced manufacturing capabilities with deep industry expertise to deliver customized solutions that exceed performance expectations. Our comprehensive approach addresses every aspect from initial design consultation through ongoing technical support.

Whether you represent a major oil service company seeking premium drilling tools or a regional distributor looking for competitive advantages, we have the capabilities and experience to support your success. Our team understands the unique challenges facing drilling operations across diverse global markets.

Ready to explore how custom PDC bit solutions can enhance your operations? Our technical specialists are standing by to discuss your specific requirements and demonstrate how our OEM/ODM capabilities can benefit your business. Contact us at hainaisen@hnsdrillbit.com to begin developing your next-generation drilling solution.