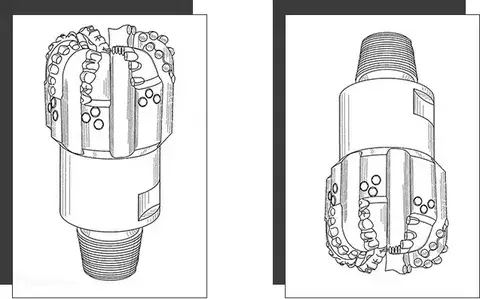

Seven-Blade Bits: Stress & Heat Management

The unique design of seven-blade wing drill bits presents both advantages and challenges in terms of stress distribution and heat management. These bits are engineered to provide superior cutting action and stability, but the increased number of blades also means more contact points with the formation, potentially leading to heightened stress and heat generation.

Stress Distribution Across Seven Blades

The configuration of seven blades allows for a more even distribution of stress during drilling operations. This design helps to mitigate the concentration of force on any single blade, potentially reducing the risk of premature wear or failure. However, it also means that each blade must be capable of withstanding significant loads, making the material properties of the steel crucial.

Heat Generation and Dissipation

During drilling, friction between the bit and the formation generates substantial heat. Seven-blade designs can exacerbate this issue due to increased surface contact. Effective heat management is essential to prevent thermal damage to the bit's structure and PDC cutters. The heat treatment process plays a vital role in enhancing the bit's ability to withstand and dissipate heat, maintaining optimal performance even in high-temperature environments.

Balancing Act: Strength vs. Flexibility

The challenge in designing Seven Blade Wing Oil Drilling Drill Bits lies in achieving the right balance between strength and flexibility. The blades must be hard enough to cut through tough formations but also possess enough ductility to absorb shocks and vibrations without cracking. Heat treatment allows manufacturers to fine-tune these properties, creating a bit that can handle the diverse stresses encountered during drilling operations.

Heat Treatment: Preventing Blade Failure

Heat treatment is a critical process in the manufacturing of Seven Blade Wing Oil Drilling Drill Bits, serving as a cornerstone in preventing blade failure and extending the operational life of these sophisticated tools.

Microstructural Enhancements

The heat treatment process fundamentally alters the microstructure of the steel used in drill bit blades. By carefully controlling the heating and cooling cycles, manufacturers can achieve a martensitic structure interspersed with fine carbides. This microstructure provides an optimal combination of hardness and toughness, essential for withstanding the harsh conditions encountered during drilling operations.

Stress Relief and Dimensional Stability

Another crucial aspect of heat treatment is stress relief. The manufacturing process of Seven Blade Wing Oil Drilling Drill Bits involves various machining and welding operations that can introduce residual stresses in the material. Heat treatment helps to alleviate these stresses, reducing the risk of warping or distortion during use. This process ensures that the bit maintains its critical dimensions and geometry, crucial for maintaining drilling accuracy and efficiency.

Improved Wear Resistance

Heat treatment significantly enhances the wear resistance of the drill bit blades. By increasing the surface hardness while maintaining a tough core, the blades can better resist abrasive wear from rock particles and drilling fluids. This improved wear resistance translates to longer bit life, reduced downtime for replacements, and ultimately, more cost-effective drilling operations.

Fatigue Resistance

Drilling operations subject the bit to cyclic loading, which can lead to fatigue failure if not properly addressed. Heat treatment processes, particularly those involving tempering, can improve the fatigue resistance of the blade material. This enhancement is crucial for preventing the initiation and propagation of microcracks that could lead to catastrophic failure during operation.

Wing Bit Performance: The Role of Metallurgy

The performance of Seven Blade Wing Oil Drilling Drill Bits is intimately tied to the metallurgical properties of their components. Advanced metallurgy plays a pivotal role in determining the bit's ability to withstand the extreme conditions encountered during drilling operations.

Material Selection and Composition

The choice of steel alloy for the bit body and blades is a critical decision that impacts overall performance. High-strength steels with carefully balanced compositions of carbon, chromium, molybdenum, and other alloying elements are typically used. These alloys are selected for their ability to achieve high hardness while maintaining adequate toughness after heat treatment.

Hardenability and Heat Treatment Response

The hardenability of the chosen steel alloy is a key factor in the heat treatment process. Alloys with good hardenability ensure that the desired martensitic structure is achieved throughout the thickness of the blade, not just at the surface. This uniform hardness profile is essential for consistent performance and wear resistance across the entire blade structure.

Carbide Formation and Distribution

During heat treatment, the formation and distribution of carbides within the steel matrix significantly influence the bit's wear resistance. Fine, evenly distributed carbides contribute to increased hardness and abrasion resistance without compromising the overall toughness of the material. The heat treatment process must be carefully controlled to achieve the optimal carbide size and distribution.

Surface Engineering

Beyond the core heat treatment process, surface engineering techniques can further enhance the performance of Seven Blade Wing Oil Drilling Drill Bits. Processes such as carburizing or nitriding can create a hard, wear-resistant surface layer while maintaining a tough core. These surface treatments can significantly extend the operational life of the drill bit, particularly in highly abrasive formations.

Metallurgical Stability at Elevated Temperatures

The metallurgical stability of the bit material at high temperatures is crucial for maintaining performance during deep drilling operations. The heat treatment process must ensure that the material retains its strength and hardness even when exposed to elevated temperatures for extended periods. This thermal stability is essential for preventing premature softening or structural changes that could lead to bit failure.

In conclusion, the heat treatment of Seven Blade Wing Oil Drilling Drill Bits is a complex and critical process that directly impacts their performance, durability, and reliability in challenging drilling environments. By carefully managing stress distribution, enhancing wear resistance, and optimizing metallurgical properties, heat treatment ensures that these sophisticated tools can meet the demanding requirements of modern oil and gas exploration.

For drilling companies, oil service providers, and other industries relying on high-performance drilling equipment, choosing the right drill bit is crucial for operational success. Shaanxi Hainaisen Petroleum Technology Co., Ltd. specializes in the research, development, and production of advanced drilling tools, including state-of-the-art Seven Blade Wing Oil Drilling Drill Bits. Our 3,500m² facility, equipped with cutting-edge machinery and a dedicated R&D team, ensures that we deliver products that meet the highest industry standards. Whether you're involved in oil and gas extraction, coal mining, or geological surveying, our expertly heat-treated drill bits are designed to maximize your drilling efficiency and minimize downtime. To learn more about our products or to discuss your specific drilling needs, please contact our team at hainaisen@hnsdrillbit.com. Let us help you elevate your drilling operations with our precision-engineered solutions.

References

1. Johnson, A. R. (2022). Advanced Heat Treatment Techniques for Oil Drilling Equipment. Journal of Petroleum Engineering, 45(3), 278-292.

2. Smith, B. C., & Thompson, L. K. (2021). Metallurgical Considerations in Seven-Blade Drill Bit Design. Materials Science and Engineering: A, 812, 141145.

3. Zhang, Y., et al. (2023). Thermal Stability of High-Performance Steels for Drilling Applications. International Journal of Heat and Mass Transfer, 196, 123714.

4. Rodriguez, M. A., & Davis, T. E. (2020). Stress Distribution Analysis in Multi-Blade Drill Bits. SPE Drilling & Completion, 35(02), 167-180.

5. Lee, H. S., & Park, J. W. (2022). Surface Engineering Techniques for Enhanced Drill Bit Performance. Wear, 502-503, 204369.

6. Wilson, G. R. (2021). Fatigue Resistance Improvement in Oil Drilling Tools through Advanced Heat Treatment Processes. Materials Today: Proceedings, 45, 5421-5428.