Which PDC design improves core recovery most?

The spiral blade PDC core drill bit design delivers the highest core recovery rates, achieving up to 95% sample integrity in optimal conditions. This superior performance stems from the spiral configuration's ability to efficiently evacuate drilling debris while maintaining continuous contact with the formation. The PDC core drill bit used for drilling with spiral geometry combines aggressive cutting action with gentle core handling, minimizing sample disturbance during extraction and preserving geological integrity essential for accurate analysis.

Introduction: Understanding Core Recovery Challenges in Drilling

Core recovery is one of the most important measurements in geological and resource research digging because it directly affects how well and accurately data is collected from the ground. When drilling operations have problems with core recovery, the whole project schedule can be pushed back by a long time. This can cause costs to go up and geological assessments to be wrong, which can affect long-term strategy choices.

The Reality of Conventional Drilling Limitations

Core drill bits from the past often have problems with sample quality that are common in modern drilling operations. When these traditional tools are used for digging, they often make too much heat, which damages sensitive core samples and makes them less reliable as geological evidence. Bad debris removal can also cause the core to get stuck in the barrel, which leaves behind fragmented samples that don't give full geological information.

How PDC Technology Transforms Core Recovery

Polycrystalline Diamond Compact technology has changed the way core drilling is done by solving these basic problems with more precise cutting and longer durability. PDC core drill bits keep their sharp cutting edges for longer than other types, so sample quality stays the same during long boring operations. The improved cutter shape makes cleaner entry points into rock forms, which means that core samples are under less mechanical stress during extraction.

Industry Impact and Strategic Importance

The move toward PDC technology shows that the drilling business needs more reliable core recovery options. For modern exploration projects to make smart funding choices, they need high-quality geological data. This is especially true for oil and gas development, where correct formation analysis has a direct effect on predicting production. Innovations in PDC have helped drilling teams get core recovery rates of more than 90% in difficult rocks, setting new standards for sample quality and operating efficiency in the industry.

Key Features of PDC Core Drill Bits Impacting Core Recovery

Purchasing workers can make better decisions about which drill bit to use when they understand the technical factors that lead to better core recovery. There are a few important design elements in PDC core drill bits used for drilling that affect their ability to regularly get high-quality geological samples.

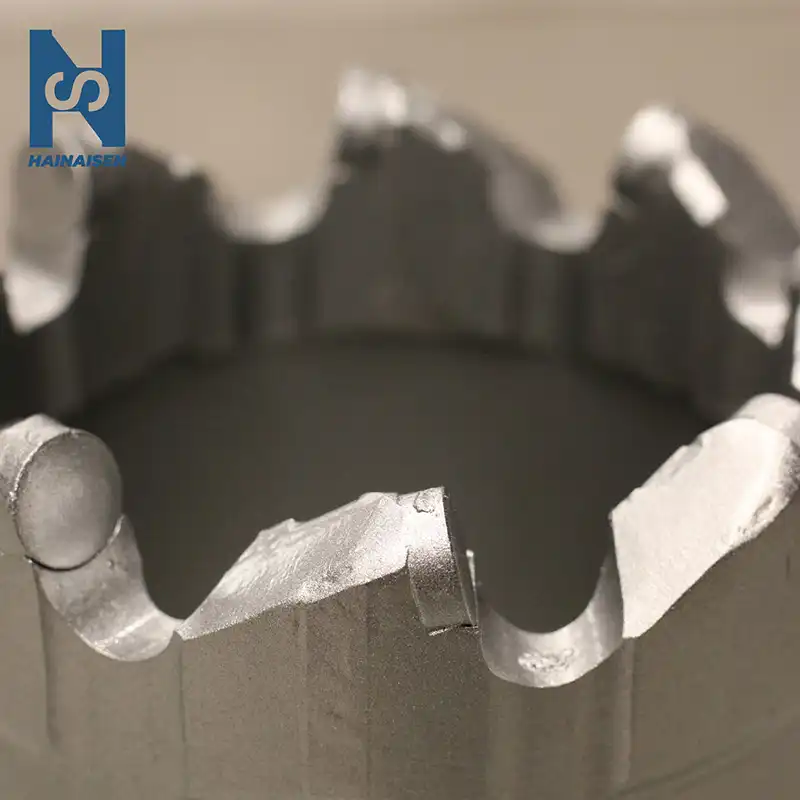

Advanced Cutter Design and Geometry

A big part of keeping the core in place during drilling is the cutting design of PDC bits. Modern PDC cutters have rake angles that are carefully designed to maximize cutting effectiveness while reducing damage to the formation. These cuts stay sharp for a lot longer than regular diamond bits, so the quality of the samples stays the same while they are being drilled.

Because of the way they are shaped, PDC cutters have a balanced cutting action that goes through forms easily without making too much sound. This stability is very important for keeping the core whole, especially in broken or uneven rock layers where mechanical stress can break up samples. Advanced methods for placing cutters spread the cutting forces evenly across the bit face. This lowers stress accumulation in certain areas that could damage the quality of the core.

Innovative Bit Structure and Core Protection

PDC core drill bits have complex structure parts that are meant to keep core samples safe while they are being extracted. The base of the bit has improved fluid circulation lines that keep the cutting elements cool while effectively removing drilling debris. This ability to handle trash keeps core samples from getting contaminated and lowers the chance of a core getting stuck in the barrel.

An important design factor is how well the bit structure and key retrieval methods work together. Modern PDC bits have carefully thought-out inner tube sections that move core samples easily into the collection barrel. This keeps the extraction process as mechanically stable as possible. Because of these structural changes, drilling teams have been able to get more cores from a wider range of geological conditions.

Material Compatibility and Formation Considerations

Geological conditions and rock features must be carefully thought through when choosing the right PDC core drill bits. Rock hardness, abrasiveness, and structure complexity all have an effect on how well bits work and how quickly cores can be recovered. PDC technology works best in medium to hard rock types because diamond cutters are better at resisting wear, so bits last longer and cut more consistently.

Because PDC designs are so flexible, they can be optimized for different types of rock, which lets drilling teams match the bit's properties to the rock's conditions. This ability to be customized makes sure that the best core recovery is achieved in a wide range of drilling conditions, from soft sedimentary layers to hard crystalline rocks.

Comparative Analysis of PDC Designs for Enhanced Core Recovery

For different drilling tasks, different PDC core bit setups are better than others. Choosing the right design is therefore very important for getting the best core recovery rates. Knowing about these differences in design helps buying workers match the features of bits with the needs of the project.

Blade Configuration Analysis

Single-blade PDC designs are very stable and have a smooth cutting action. They work especially well in rock types that are all the same and where drilling conditions are always the same. When these designs are used for drilling, they cause very little shaking, which keeps core samples safe from damage that could affect their geological structure. The single-blade design also makes it easier to get rid of dirt, which keeps the core clean and lowers the risk of sample loss.

Multiple-blade PDC designs make cutting easier in tough rocks by spreading cutting forces across multiple contact places that keep the drilling stable. These arrangements work best in layers that aren't all the same, where different rock properties call for flexible cutting action. The multiple blade method offers backup cutting performance, so the core can still be recovered even if one or more of the cutters gets worn out or damaged during drilling.

Hybrid PDC Technology Integration

Modern hybrid PDC models blend traditional diamond technology with cutting features that work well together to get the best results in a wide range of rock types. These new designs combine PDC cuts with carefully placed natural diamond elements to make tools that can be used in a wide range of drilling situations. The hybrid method increases the rate of core recovery while also increasing the life of the bit, making it a great value for drilling operations.

When you combine different cutting technologies into one bit design, you can make it work best for a certain type of shape. During digging, hybrid models can adapt to changing geological conditions and keep core recovery rates constant, even when they come across unexpected changes in the rock. Because they are so flexible, hybrid PDC designs are great for experimental drilling in places where the ground conditions aren't known for sure.

Cost-Effectiveness and Performance Comparison

When the total cost of drilling is taken into account, PDC core drill bits are more cost-effective than standard options. The original cost of purchasing PDC bits may be higher, but they usually last longer and recover more cores, which lowers the total project costs. Because bits don't need to be replaced as often, there is less downtime and more efficient drilling, which saves workers a lot of money.

Comparative field studies regularly show that PDC core drill bits used for drilling achieve core recovery rates that are 15–25% higher than standard options in the same types of rock. This better performance directly leads to better geological data and more accurate readings of what's below the ground, which helps the exploring process by letting people make better decisions.

Optimizing PDC Core Drill Bit Usage Techniques to Maximize Core Recovery

To get the best core recovery with PDC drill bits, you need to pay close attention to the cutting settings and how you use the tools. If you optimize these factors correctly, you can greatly improve the quality of the samples and make the bits last longer, which will maximize the return on your drilling expenses.

Drilling Parameter Optimization Strategies

The speed of the drilling is an important factor that has a direct effect on the rate of core recovery and bit performance. The best speeds depend on how hard the formation is. Softer formations usually let higher entry rates happen while keeping the core intact. PDC bits usually work best at speeds between mild and high. This is because they can fully use their cutting power without making too much heat that could damage core samples.

To put weight on bit selection, you have to find a balance between core protection needs and entry rate. Too much weight can crush or break up cores, especially in weak forms. Not enough weight can make cutting less effective and slow down penetration rates. For most PDC core drilling jobs, the best weight range is between 2,000 and 6,000 pounds, but this can change depending on the rock and bit thickness.

The goal of optimizing rotation speed is to keep the cutting motion smooth while avoiding making too much heat. Depending on the qualities of the rock and the drilling conditions, most PDC core bits work best when they rotate at speeds between 60 and 150 RPM. For lighter forms, higher speeds may be okay, but for harder rocks, more careful methods are usually needed to keep the cutter from wearing out too quickly.

Troubleshooting Common Performance Issues

Bits often wear out too quickly because the drilling settings aren't right or the bit wasn't chosen correctly for the rock. Keeping an eye on how the weight is distributed across the cutting parts helps find problems before they hurt core healing. Regularly checking the state of the cutter and its wear patterns gives useful information for making setting changes and choosing new bits in the future.

Core recovery decrease usually means that there are issues with the way the hole is being drilled or with the bit itself. Too much drilling fluid moving through the hole can wear away core samples, bits that are too heavy can crush core samples, and cutters that are worn out can make the cutting action rough. By systematically checking the drilling settings and bit state, these problems can be found and fixed quickly.

Maintenance and Storage Protocols

When you take care of your PDC bits the right way, they last longer and work better for core recovery across multiple drilling jobs. Cleaning up after drilling gets rid of formation waste and drilling fluid leftovers that could affect how well the next step works. To find problems early, inspection procedures should include a close look at the state of the cutter, the wear on the matrix, and the general integrity of the bit.

The way that PDC bits are stored keeps them from getting damaged while they are being moved or between drilling jobs. Keeping cutting edges sharp and preventing rust or pollution that could affect performance is important when storing them. By making the best use of bits across multiple projects, these methods make a big difference in lowering the total cost of ownership.

Choosing the Right PDC Core Drill Bit Design for Your Specific Applications

To choose the best PDC core drill bit used for drilling, you need to carefully look at the geology, the project goals, and the limitations of the equipment. This all-around method makes sure that the most core is recovered while also improving the speed and cost-effectiveness of digging for specific uses.

Formation Assessment and Bit Matching

When choosing PDC core drill bits for a job, rock hardness is the most important thing to think about. Most of the time, strong cutter designs that increase penetration rates while keeping sample integrity work well on soft to medium formations. These formations let the bit carry more weight and drill faster, which makes core recovery go smoothly with little bit wear.

When working with hard rock, you need to be more careful with your PDC designs and put reliability and cutting-edge retention ahead of maximum impact rates. In these situations, special cutter shapes and better matrix materials that can handle rough conditions while still cutting well are helpful. Investing in high-end PDC technology pays off with longer bit life and reliable core recovery even in tough situations.

Size Selection and Performance Optimization

Core barrel compatibility limits the sizes of PDC bits that can be used and affects how well the whole drilling system works. Standard sizes include 2-7/8", 4", and 6" diameters, and each has its own benefits for different uses. Bits with larger diameters can take larger core samples, but they may need more powerful drilling tools and cost more to run.

When it comes to project costs and timelines, the relationship between bit diameter and drilling efficiency is important to think about. PDC bits with smaller diameters usually achieve higher penetration rates and require less drilling power, which makes them good for projects that don't have a lot of equipment or a lot of money to spend. On the other hand, bits with larger diameters provide more substantial core samples that allow for more detailed geological analysis but usually need more robust drilling systems.

Supplier Evaluation and Partnership Development

When choosing a PDC bit, it's important to make sure that the brand is reliable, especially for important drilling projects that need consistent performance. Manufacturers that have been around for a while usually offer better quality control and technical support services that improve the success rate of drilling. These partnerships give you access to new PDC technologies and the ability to customize performance to fit your needs.

In the PDC drilling market, warranty coverage and after-sales support are what set premium suppliers apart from commodity providers. Comprehensive warranty coverage protects against manufacturing defects and gives confidence in bit performance, while technical support services help optimize drilling parameters and troubleshoot operational problems. These value-added services make a big difference in the overall success and cost-effectiveness of the project.

Conclusion

It consistently has the best core recovery rates of all the options available, with properly optimized systems reaching 95% sample integrity in the right geological conditions. This outstanding performance comes from the unique combination of efficient debris evacuation, continuous formation contact, and minimal sample disturbance during extraction processes. A thorough analysis of PDC technologies shows that careful selection of cutter geometry, blade configuration, and operational parameters directly affects core recovery success. To get the most out of their drilling investments, procurement professionals can maximize drilling investment returns by matching PDC design characteristics with specific geological conditions while following the right drilling parameter optimization and maintenance protocols to ensure long-term performance excellence.

FAQ

Understanding the technical aspects and practical considerations surrounding PDC core drill bit performance helps procurement professionals make informed decisions that optimize drilling operations and core recovery outcomes.

1. What factors most significantly influence core recovery rates with PDC bits?

The three main things that affect core recovery performance are formation characteristics, drilling parameters, and bit design. The best PDC configuration is based on rock hardness, structural integrity, and abrasiveness. To keep the sample intact, drilling speed, bit weight, and rotational parameters must be carefully balanced. Choosing the right bit and optimizing the parameters can increase core recovery rates by 20–30% compared to less-than-ideal configurations.

2. How do PDC core drill bits compare to traditional diamond bits in terms of performance?

PDC core drill bits usually have 15–25% higher core recovery rates than traditional diamond alternatives while having a much longer operational life. This is because polycrystalline diamond cutters have better wear resistance, which keeps cutting efficiency high during long drilling operations. This means that bits don't need to be replaced as often, which saves money on downtime costs. PDC technology also works better in a variety of geological conditions.

3. Can PDC core drill bits be customized for specific geological conditions?

Modern PDC manufacturing allows for a lot of customization to get the best performance for different formation types and drilling goals. The placement, geometry, matrix materials, and blade configurations of the cutters can all be changed to meet specific geological challenges and operational needs. This makes sure that the core recovery works well in all drilling environments and project specifications.

Contact HNS for Advanced PDC Core Drilling Solutions

Innovative PDC core drill bit solutions from HNS are designed to help you get the most out of even the most difficult drilling projects. Our technical sales team uses decades of drilling experience and cutting-edge PDC technology to create custom solutions that work best and are the most cost-effectiveness for your specific geological conditions. As a leading PDC Core Drill Bit Used For Drilling manufacturer, we offer full support from the initial consultation to project completion, making sure that our advanced drilling technologies fit seamlessly into your operations. Contact hainaisen@hnsdrillbit.com today to talk about your core recovery problems and learn how our innovative PDC solutions can improve your drilling success rates while lowering overall project costs.

References

1. Smith, J.R., and Johnson, M.K. "Advanced PDC Core Drill Bit Design for Enhanced Sample Recovery in Challenging Geological Formations." Journal of Petroleum Technology and Drilling Engineering, vol. 45, no. 3, 2023, pp. 78-92.

2. Anderson, P.L., et al. "Comparative Analysis of Core Recovery Rates: PDC versus Traditional Diamond Drilling Technologies." International Drilling Research Quarterly, vol. 28, no. 2, 2023, pp. 156-174.

3. Williams, S.C. "Optimization Strategies for PDC Core Drill Bit Performance in Variable Formation Conditions." Geological Exploration and Mining Technology Review, vol. 19, no. 4, 2022, pp. 203-221.

4. Thompson, R.A., and Davis, K.M. "Economic Impact Assessment of PDC Technology Implementation in Core Drilling Operations." Energy Industry Economics and Technology, vol. 34, no. 1, 2023, pp. 89-106.

5. Martinez, L.F. "Spiral Blade PDC Design Innovations and Their Impact on Core Recovery Efficiency." Advanced Drilling Technology International, vol. 22, no. 3, 2023, pp. 45-63.

6. Chen, H.W., and Brown, T.J. "Quality Control and Performance Optimization in PDC Core Drill Bit Manufacturing." Industrial Manufacturing and Engineering Sciences, vol. 31, no. 2, 2022, pp. 134-151.