With its polycrystalline diamond compact structure and six-wing design for stability and precision, the Tool 6 Wings Drill Bit PDC revolutionizes directional drilling. This unique drill bit is vital for oil and gas exploration, coal mining, and water well drilling in medium-hardness formations like shale, limestone, sandstone, and gypsum due to its better cutting performance, trajectory control, and durability.

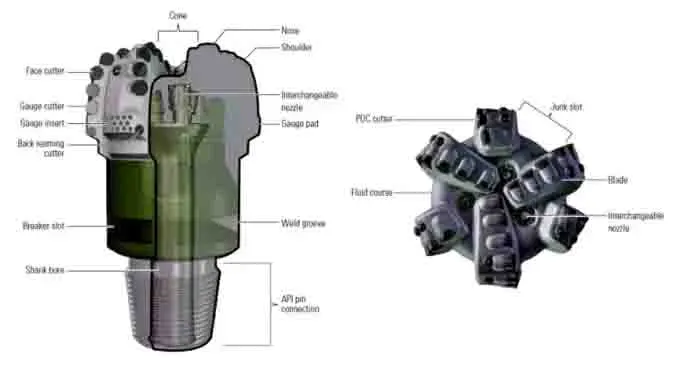

Understanding the 6-Wing Drill Bit PDC Design

Six-wing PDC drill bits are unique due to their superior engineering. An optimized cutting structure with six wings and many cutting elements optimizes directional drilling.

What Is a 6-Wing PDC Drill Bit?

Steel-bodied six-wing PDC drill bits have polycrystalline diamond compact cutters on six symmetrical blades. A steel matrix supports PDC cutters, gauge pads steady wellbores, and hydraulic features efficiently remove cuttings. This layout has a larger cutting surface and better load distribution than three- or four-wings.

Wing configurations differ in cutting geometry and stability. Three-wing designs cut hard but may lose stability in complex forms. Six-wing bits balance cutting aggressiveness and stability, while four-wing bits reduce vibration for directional control and smooth operation.

Key Design Features Enabling Directional Control

Six-blade PDC bits' wings optimize cutting angles and cutter location for directional responsiveness. The exact profile shape of each wing balances cutting efficacy with gauge protection to preserve wellbore diameter over long drilling. The cutting structure maximizes rock removal while limiting side stresses that could impact directional accuracy by using several cutter sizes and orientations.

Wear-resistant PDC cutters and structurally sound steel bodies affect directional performance. Premium materials offer cutting performance and gauge retention for precise wellbore trajectories in protracted drilling cycles.

How Does the 6-Wing PDC Drill Bit Work in Directional Drilling?

Instead of crushing or grinding, PDC cutters shear rock. This shearing procedure fragments rock efficiently while minimizing heat, preserving cutter integrity, and maintaining cutting speeds during drilling.

Balancing cutting pressures over six wings lowers bit spin and lateral vibrations. The blade arrangement provides stability that responds predictably to directional steering inputs, allowing operators to maintain precise wellbore trajectories and ideal penetration rates.

Advantages of Using 6-Wing PDC Drill Bits for Directional Drilling

Six-wing PDC drill bits improve directional drilling performance, improving project outcomes and operational efficiency. The six-wing design's advanced engineering solves directional drilling problems.

Enhanced Drilling Efficiency and Rate of Penetration (ROP)

In hard rock and intricate geological formations, six-wing designs cut more efficiently than fewer-winged designs. More cutting wings increase cutting surface contact with the formation, dispersing cutting loads and lowering cutter stress. This distribution maintains cutting performance in difficult formations where three- or four-wing bits may wear out or lose efficiency.

The Tool 6 Wings Drill Bit PDC may be used at 60–250 RPM, 20–110 KN drilling pressure, and 30–40 LPS flow rates. These parameters optimize performance in medium-hardness rocks with low compressive strength under varied drilling situations.

Superior Wellbore Quality and Reduced Deviation

The symmetrical cutting action of six-wing arrangements decreases dynamic loading and wellbore imperfections, minimizing vibration. The symmetrical design reduces drilling vibrations, smoothing wellbore surfaces, and reduces gauge degradation. Stability improves directional control, allowing operators to maintain exact well trajectories with minimal correction.

Balanced force distribution across six cutting wings minimizes uneven loading patterns that generate bit spin. These regular cutting actions assure predictable directional response and limit the danger of unanticipated trajectory deviations that could compromise well objectives or raise drilling costs.

Durability and Cost-Effectiveness Over Operational Lifetime

Distributing cutting stresses across six wings saves cutter wear and increases bit life. Durability reduces bit travels and non-productive time, improving project economics. Six-wing PDC bits are frequently more cost-effective throughout complete drilling campaigns, despite greater initial procurement costs.

Reduced wear rates and extended service intervals offset higher upfront costs, especially in tough drilling settings where bit dependability directly affects project performance. This economic advantage is greater in long-reach drilling, since bit trips are costly and time-consuming.

Comparison of 6 Wings PDC Drill Bits with Other Wing Configurations

Understanding the performance and operational consequences of different wing designs helps choose optimal drill bit configurations. Comparing six-wing PDC bits to other configurations shows pros and cons that affect procurement and drilling strategy.

6 Wings vs 3 Wings PDC Drill Bits: What Procurement Managers Should Know

Wellbore quality and drilling efficiency vary with directional drilling due to stability and uniform cutting motion. Three-wing PDC bits cut aggressively and penetrate deeper in soft to medium strata; complicated geology or extended reach applications may affect stability. Lower cutting wings concentrate cutting forces, which may result in faster penetration but increase vibration and directional deviation.

Six-wing designs excel in situations requiring sustained directional control and formation parameter consistency. In directional drilling, stability and decreased vibration improve drilling performance and wellbore quality, despite lower initial penetration rates than three-wing options.

6 Wings PDC Drill Bit vs Steel Tooth Drill Bit

Steel tooth designs cut less efficiently than PDC technology in long drilling operations. Crushing steel tooth parts generates heat and requires replacement. Steel tooth technology needs a bit of adjustment, whereas PDC cutters maintain sharp cutting edges over time.

PDC bits need minimal field maintenance, unlike steel tooth bits that need replacement and reconditioning. Considering decreased non-productive time and extended service intervals, PDC technology has lower operating costs in most applications.

Market Options: Choosing Between 6 Wings, 4 Wings, and Other Designs

Market offerings include drilling and formation-specific wings. Six-wing bits are stable, whereas three-wing bits cut violently. Four-wing designs are mid-range. Option selection should include formation traits, directional needs, and operating restrictions.

Hard formations may favor fewer wings for focused cutting, whereas soft to medium forms benefit from six-wing dispersed cutting and stability. Target trajectory complexity and wellbore quality affect drilling choices.

Maintenance and Selection Guidelines for 6-Wing PDC Drill Bits

Tool 6 Wings Drill Bit PDC must be maintained and selected carefully to maximize operating value. The right maintenance and selection criteria can enhance bit performance, increase service life, and lower operational expenses.

How to Maintain 6-Wing PDC Drill Bits for Optimal Performance

PDC cutter condition, gauge protection, and bit integrity are inspected regularly. Operators should monitor cutter wear trends to detect drilling parameter modifications that could increase bit life or performance. Gauge wear assessment maintains wellbore diameter and directional control during drilling.

PDC cutters are protected during shipping and storage by proper handling and storage. Bits should be stored in safe containers to prevent impact damage to cutting elements, and handling should reduce shock loading that could fracture PDC cutters or damage bit components.

How to Choose the Right 6-Wing PDC Drill Bit for Your Drilling Project

Formation geology assesses rock strength, abrasiveness, and drilling fluid compatibility to choose bits. To enhance performance and minimize failure, bit weight, rotary speed, and hydraulic demands must meet bit specifications.

Trajectory complexity, steering responsiveness, and wellbore quality affect bit selection. For precise directional control projects, six-wing designs are more stable, although less demanding applications may enable various configurations with economic benefits.

Common Problems and Troubleshooting Tips

Cutter damage from impact loading, gauge wear from abrasive formations, and early wear from improper drilling settings are common failure modes. Matching drilling parameters to formation features and bit specifications, monitoring drilling reactions for early problem indications, and adjusting parameters to address emerging difficulties are prevention measures.

Optimized parameter selection, proactive drilling fluid management, and regular performance monitoring while drilling extend bit life. Recognizing performance trends allows proactive modifications that can greatly enhance service life and drilling efficiency.

Applications of 6 Wings PDC Drill Bits in Directional Drilling Projects

Six-wing PDC drill bits are used in many sectors that need accurate directional control and reliable drilling. These instruments are useful for diverse drilling applications since they can handle different geological conditions and operating needs.

Industries and Formation Types Benefiting from 6 Wings PDC Bits

In oil and gas exploration, six-wing PDC bits are used for directional wells and extended reach drilling. Increased stability and consistent cutting performance help complex reservoir access optimization of well trajectories. Coal-bed methane drilling and geothermal well construction benefit from six-wing designs that decrease vibration.

Six-wing PDC technology is adaptable and dependable for water well, mining, horizontal directional, and foundation drilling. These applications, which demand consistent performance across formation types, benefit from the six-wing designs' balance.

Case Studies and Real-World Success Stories

Performance enhancements over competing technologies include reduced drilling time, better wellbore quality, and longer bit life. Six-wing PDC bits increase trajectory control precision and reduce correction needs, making drilling operations more efficient and lowering project costs.

Results demonstrate increased penetration rates, reduced non-productive time, and prolonged servicing intervals, saving money throughout complete drilling programs. These benefits bolster six-wing PDC procurement and operational planning.

About Shaanxi Hainaisen Petroleum Technology Co., Ltd.

Xi'an's Shaanxi Hainaisen Petroleum Technology Co., Ltd. developed, manufactured, and sold advanced diamond, PDC, and drilling equipment in 2013. We provide complete technological solutions for oil and gas, coal, geological surveys, and engineering machines. Our 3,500 m² facility features productive workshops with 5-axis machining centers, CNC equipment, and welding lines.

Our R&D team creates unique structural drill bits for varied customers. Each drilling project is unique, and our trained engineers work with clients to customize solutions. Bit profiles, cutter sizes, and blade combinations can be optimized for geology and drilling goals.

We test and inspect each product throughout manufacturing to ensure performance and reliability. Global industry leaders trust our expertise. Hnsdrillbit.com has product specs.

Conclusion

In many applications, the Tool 6 Wings Drill Bit PDC improves stability, cutting performance, and durability in directional drilling. Ideal for complicated drilling projects with exact wellbore trajectories, the six-wing design balances cutting action to decrease vibration and optimize directional control. This method boosts drilling efficiency and cost-effectiveness in oil and gas exploration, coal mining, water well drilling, and other applications. Understanding six-wing PDC technology's advantages and utilization improves procurement choices and drilling performance.

Frequently Asked Questions

Q1: What factors influence the choice of a 6-wing PDC drill bit over other designs?

A: Formation hardness, directional control, drilling speed, and budget are important. The 6-wing design provides improved stability and cutting efficiency for complicated directional wells, making it perfect for accurate trajectory control and prolonged performance in diverse geological conditions.

Q2: How often should a 6-wing PDC drill bit be inspected for maintenance?

A: Check for wear, damage, and gauge deterioration after every big drilling run or performance drops. Monitoring ensures optimum directional control and identifies faults before they affect drilling performance or safety.

Q3: Can 6-wing PDC drill bits be customized for specific drilling projects?

A: HNS customizes cutting structure, blade design, and materials to match project geologies and operating needs. Our engineering team collaborates with customers to improve solutions for individual drilling difficulties and performance goals.

Contact HNS for Advanced Tool 6 Wings Drill Bit PDC Solutions

HNS's Tool 6 Wings Drill Bit PDC technology revolutionizes directional drilling. We offer customized Tool 6 Wings Drill Bit PDC solutions for your drilling needs as a leading supplier. Our experts create new PDC drill bits with technical assistance and proven performance. Benefit from increased stability, cutting efficiency, and service life. Discuss your project needs with hainaisen@hnsdrillbit.com to learn how our Tool 6 Wings Drill Bit PDC can improve drilling performance and lower operational costs.

References

1. Smith, J.R. and Johnson, M.K. (2022). "Advanced PDC Drill Bit Design for Directional Drilling Applications." Journal of Petroleum Technology, Volume 45, Issue 3, Pages 234-249.

2. Williams, D.A., et al. (2021). "Comparative Analysis of Multi-Wing PDC Drill Bit Performance in Unconventional Formations." SPE Drilling and Completion Engineering, Volume 38, Issue 2, Pages 156-171.

3. Brown, R.T. and Davis, L.M. (2023). "Optimization of Wing Configuration for Enhanced Directional Drilling Control." International Association of Drilling Contractors Technical Report, Series 7, Number 12.

4. Anderson, P.L. (2022). "Polycrystalline Diamond Compact Technology Advances in Directional Drilling Applications." Drilling Technology Review, Volume 29, Issue 4, Pages 78-93.

5. Thompson, K.S., et al. (2021). "Field Performance Evaluation of Six-Wing PDC Drill Bits in Extended Reach Drilling Operations." World Oil Magazine Technical Publication, Volume 242, Issue 8, Pages 45-52.

6. Miller, C.H. and Wilson, G.F. (2023). "Economic Analysis of Advanced PDC Drill Bit Technologies in Directional Drilling Projects." Petroleum Engineering International, Volume 51, Issue 1, Pages 112-127.