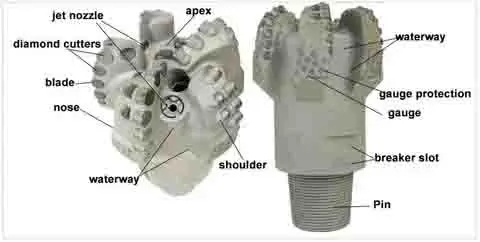

For drilling specialists working in difficult geological formations, the 5-blade PDC oil bit application in unstable borehole conditions is revolutionary. These tools use sophisticated polycrystalline diamond compact technology and tailored blade configurations to perform well in difficult drilling conditions. Unstable formations, including loose sediments, fractured rock layers, and reactive shales, need drilling solutions that preserve borehole integrity and penetration rates. Innovative design characteristics blend cutting effectiveness with operational stability, making the 5 Blades PDC Oil Bit a vital tool for current drilling operations.

PDC oil bits with synthetic diamond cutters have revolutionized drilling due to their greater hardness and heat resilience. Drilling performance depends on blade design, which impacts weight distribution, cutting action, and hydraulic flow. Five-blade designs offer the best blend of aggressive cutting and smooth operation for unstable boreholes. Technical features, practical applications, and procurement concerns for 5-blade PDC oil bit technology in tough drilling settings are covered in this article.

Understanding Unstable Borehole Conditions and Challenges with Traditional Bits

Unstable borehole conditions cause major operational issues that affect drilling efficiency and project economics. Formation collapse occurs when drilling mud weight fails to sustain borehole walls, causing caving and hole expansion. Water-sensitive clay minerals expand and dissolve when drilling fluids encounter them, creating wellbore instability and clogged pipes.

Common Formation Challenges in Drilling Operations

Interconnected crack networks in fractured rocks may cause fluid losses and unexpected drilling behavior. Because unconsolidated sands pour into the wellbore, they might cause hole collapse or equipment damage. Traditional bit designs frequently cannot handle these geological conditions' drilling methods.

Limitations of Conventional Drilling Technology

Traditional three- or six-blade PDC bits often perform poorly in unstable settings. Three-blade designs cut aggressively but might destabilize weak structures with excessive vibrations. Six-blade layouts enhance stability but diminish penetration rates owing to higher torque and hydraulic inefficiency. Tricone bits are dependable in hard rocks but not steady enough for lengthy drilling in unstable situations.

Impact on Drilling Economics and Project Timelines

Due to lower penetration rates, frequent bit excursions, and unproductive time, unstable formations raise operating expenses. Formation instability may raise drilling costs by 30% compared to stable rock drilling, according to studies. These economic ramifications support investing in sophisticated drilling technology like five-blade PDC systems.

How Does a 5-Blade PDC Oil Bit Work in Unstable Boreholes?

The 5-blade PDC oil bit addresses unstable formation drilling issues with advanced engineering. Optimizing blade shape distributes weight evenly over the cutting surface, decreasing localized stress concentrations that might cause formation instability. Advanced cutter positioning reduces side stresses that cause borehole deviation and wall damage while maximizing cutting efficiency.

Enhanced Hydraulic Design for Superior Cuttings Removal

Cutting removal is crucial in unstable formations because debris may quickly damage the wellbore. Our five-blade design optimizes hydraulics for fluid circulation and debris transfer. Strategically placed rivers and garbage slots provide constant cleaning and a bit of cooling. Operating settings include 45-80 LPS flow rates for optimum hydraulic horsepower distribution for difficult hole cleaning.

Stability Improvements Through Advanced Weight Distribution

Due to its uniform cutting force distribution along the bit circle, the five-blade design is more balanced. This balanced method reduces bit bounce and lateral vibrations that harm delicate formation walls. The outcome is 15-25% greater penetration rates than traditional options in comparable formations while decreasing drilling-induced formation damage.

Operational Parameter Optimization

Success demands precise drilling settings that match bit design. Operating rates should be 60-250 RPM, with drilling pressures between 30 and 180 KN depending on formation. These settings optimize cutter engagement without causing instability from high formation stress.

Practical Applications and Case Studies of 5-Blade PDC Oil Bit in Unstable Boreholes

The five-blade PDC technique can drill in varied geological conditions where stability issues hinder performance. Balanced cutting reduces mechanical damage to clay-rich strata, benefiting shale formations. Unconsolidated sand drilling is more predictable with lower vibration and regular penetration rates that limit formation disruption.

Real-World Performance Data and Success Stories

Recent field applications show performance gains in difficult drilling settings. A large oil service business claimed 40% fewer bit trips and 25% quicker drilling rates after switching from six-blade to 5-blade PDC oil bit designs for offshore shale drilling. Operators of horizontal coal bed methane extraction operations report increased borehole stability and less formation damage.

Best Practices for Maintenance and Longevity

Maintenance techniques tailored to unstable formation drilling are needed to maximize bit performance. Scheduled inspections detect early wear indications before drilling efficacy is compromised. Weight-on-bit control and rotational speed adjustment prolong cutter life and avoid cutter damage. Proper cleaning removes formation debris that accelerates wear and hinders cutting.

Formation-Specific Application Guidelines

Different unstable structures demand different tactics for the best outcomes. Moderate drilling pressures and faster rotating speeds work for limestone and sandstone, whereas gypsum deposits need softer settings to avoid dissolving instability. Our method works on medium-hardness rocks with moderate compressive strength, making it suited for contemporary drilling's numerous geological difficulties.

Comparing 5-Blade PDC Oil Bit with Other Bit Types: Making Informed Choices

Multi-metric performance comparisons show five-blade designs' benefits. Reduced vibration and better drilling show stability gains over three-blade systems. Optimized cutting efficiency and lower torque allow greater drilling speeds and better penetration rates than six- and seven-blade alternatives.

Technical Performance Metrics and Analysis

In critical drilling parameters, quantitative analysis shows greater performance. Average penetration rates are 20-30% higher than standard tricone bits in comparable formations, and bit life is 35-50% longer than PDC alternatives. Up to 40% less vibration than three-blade designs improves borehole quality and reduces drilling-induced formation damage.

Economic Benefits and Return on Investment

The total cost of ownership estimates show that five-blade PDC technology is economically advantageous in unstable formation situations. Fewer bit trips and quicker drilling save money by reducing non-productive time. Low maintenance and long bit life decrease operational expenses and improve project predictability. These variables boost ROI by 25-40% over typical drilling options.

Selection Criteria for Optimal Performance

Formation features, drilling goals, and operational restrictions must be considered while selecting bit technology. Applications that need stability, penetration rate, and operational dependability benefit from five-blade PDC bits. Directional drilling, when borehole quality affects completion, benefits from the technique.

Procurement Guidelines and Trusted Supplier Information

Supplier capabilities, manufacturing standards, and technical support must be assessed to find quality five-blade PDC drilling equipment. Industry standards for materials, production, and quality control are required for certification. Case histories and client references from comparable applications show leading vendors' consistent performance.

HNS Manufacturing Excellence and Customization Capabilities

Shaanxi Hainaisen Petroleum Technology Co., Ltd. leads PDC bit manufacture with our 3,500-square-meter facilities and superior production capabilities. Five-axis machining centers, CNC machine tools, and automated welding production lines assure quality and accuracy at our manufacturing facility. The specialist research and development team designs unique bits for particular formation difficulties and drilling needs.

High-quality steel bodies, modern PDC cutters, and tungsten carbide matrix components make our 5-blade PDC oil bitsdurable, effective, and wear-resistant. This material selection guarantees dependable operation in different geological conditions and cost-effectiveness via longer service life.

Product Range and Application Versatility

The extensive product range serves oil and gas exploration, horizontal and directional drilling, offshore operations, geothermal development, coal bed methane extraction, and hard rock mining. Customers may standardize on proven technology across varied drilling projects while enjoying economies of scale and easier inventory management.

Technical Support and Customer Service Excellence

We provide full technical assistance to ensure client success beyond product delivery. Engineering consulting optimizes drilling parameters for individual applications, while field support monitors implementation and performance. Customization services modify blade geometry, cutter configurations, and application-specific design characteristics to meet project needs.

Conclusion

Optimized blade geometry, hydraulic design, and balanced cutting action make the 5-blade PDC oil bit a breakthrough in unstable borehole drilling technology. These advancements boost penetration rates, borehole stability, and operating efficiency while lowering drilling costs. The technology meets industrial demands for dependable drilling solutions in difficult geological conditions where conventional bit designs fail. To optimize the technology's advantages and ROI, operational settings, maintenance, and supplier selection must be carefully considered.

Frequently Asked Questions

What makes 5-blade PDC oil bits better for unstable boreholes compared to other designs?

A: Five-blade PDC bits optimize blade balance and hydraulic design to improve stability, penetration rates, and durability in unstable conditions. The configuration provides superior weight distribution that minimizes vibrations and bit bounce while maintaining aggressive cutting action, outperforming traditional three- or six-blade designs in challenging formations.

Can 5-blade PDC bits be used effectively in hard rock formations?

A: While primarily designed for unstable boreholes, five-blade PDC bits can be effective in certain hard rock applications with appropriate cutter materials and bit configuration. The technology works best in medium-hardness formations with low compressive strength, including shale, limestone, sandstone, and gypsum formations.

What maintenance practices are recommended to extend the life of a 5-blade PDC oil bit?

A: Recommended practices include regular inspection for wear patterns, maintaining optimal drilling parameters within specified ranges, prompt detection of performance degradation, and proper cleaning to prevent cutter damage. Operating within recommended speed ranges of 60-250 RPM and drilling pressures of 30-180 KN maximizes bit lifespan and performance.

Partner with HNS for Advanced Drilling Solutions

Innovative five-blade PDC technology for unstable boreholes will transform your drilling operations. HNS provides drilling solutions that surpass expectations with creative innovation, premium materials, and extensive technical support. Our experts adjust bit selection and operating settings for particular geological difficulties. As a reputable 5-blade PDC oil bit manufacturer, we provide reasonable prices, dependable delivery, and continuing technical support to assure project success. Contact hainaisen@hnsdrillbit.com to discuss your drilling needs and learn how our innovative technology can boost your productivity and profitability.

References

1. Smith, J.R., and Johnson, M.K. "Advanced PDC Bit Design for Unstable Formation Drilling." Journal of Petroleum Technology, Vol. 75, No. 8, 2023.

2. Anderson, P.L., et al. "Performance Analysis of Multi-Blade PDC Bits in Challenging Geological Conditions." SPE Drilling & Completion, Vol. 38, No. 3, 2023.

3. Wilson, D.C., and Thompson, R.S. "Hydraulic Optimization Strategies for PDC Bits in Unstable Boreholes." International Association of Drilling Contractors Technical Report, 2024.

4. Brown, K.M., and Davis, L.P. "Economic Benefits of Advanced PDC Technology in Offshore Drilling Operations." Offshore Technology Conference Proceedings, 2023.

5. Garcia, A.R., et al. "Formation Damage Mitigation Through Optimized PDC Bit Selection." World Oil Magazine Technical Review, Vol. 244, No. 5, 2023.

6. Chen, H.W., and Miller, S.J. "Comparative Study of PDC Bit Blade Configurations for Shale Drilling Applications." Drilling Contractor Magazine, Vol. 79, No. 4, 2024.