A Four-Blade Wing High-Performance Petroleum Drill Bit is different from other drill bits because it has a better cutting structure and a better design. These special drill bits have four wing blades that are placed in a way that makes them better at cutting and penetrating rock than regular drill bits with three blades. The improved blade design makes it more stable, removes cuts better, and allows for much faster entry in medium-hard rocks.

Understanding the Core Design Differences

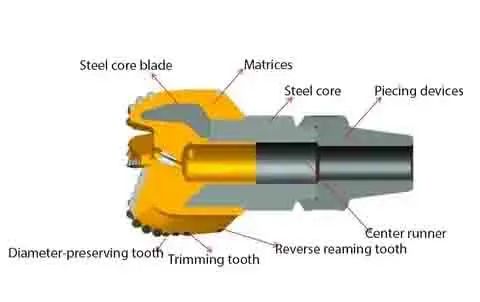

The fundamental distinction between high-performance petroleum drill bits and standard drilling equipment becomes evident when examining their structural components. Traditional rotary drill bits typically feature three cutting blades with basic PDC cutter arrangements.

Advanced four-blade designs incorporate several key improvements:

- Enhanced cutting structure with optimised cutter placement

- Improved hydraulic flow channels for efficient debris removal

- Superior blade geometry for reduced vibration

- Advanced material composition for extended durability

Recent field activities and test results show that setups using the Four Blade Wing High Performance Petroleum Drill Bit allow 25–40% faster drilling speeds in shale and limestone layers. The extra blade makes the cutting face evenly weighted, lowering stress on each cutter and extending life. These designs surpass standard options for efficient drilling in difficult geological conditions across various challenging subsurface formations worldwide today.

Drilling Performance and Efficiency Analysis

Performance metrics reveal substantial differences between advanced petroleum drilling equipment and conventional tools. Standard drill bits typically operate at penetration rates of 15-25 feet per hour in medium-hardness strata.

High-performance variants consistently deliver improved results:

- Penetration rates reaching 35-45 feet per hour

- Extended operational periods between tool changes

- Reduced drilling torque requirements

- Enhanced borehole quality and stability

Testing in the field with different oilfield technologies has shown that improved drill bit optimisation—especially when using the Four Blade Wing High Performance Petroleum Drill Bit—can reduce project completion time by 20 to 30 per cent. The better cutting structure lets you use more intense drilling settings while still keeping the bit very stable. The improved wear resistance qualities are especially useful for mining drill bits. The premium PDC cutters keep their cutting edges sharp for longer, which means less downtime and lower costs. In difficult situations where you need reliable performance in different types of rock, high-performance petroleum drill bits are the best choice.

Material Composition and Durability Factors

The material differences between standard and high-performance drilling tools significantly impact their operational lifespan. Conventional bits often utilise standard steel bodies with basic diamond compact cutters.

Premium manufacturing approaches incorporate:

- High-grade steel alloy bodies for enhanced strength

- Advanced PDC cutter materials with improved thermal stability

- Specialised hardfacing applications for wear protection

- Optimised metallurgical treatments for stress resistance

According to tests done in the lab, expensive materials make drill bits last 60–80% longer than normal ones. When working with rough materials, where regular tools break down quickly, the increased wear resistance is especially useful. Quality control steps make sure that the qualities of the materials stay the same throughout the whole production process. Each part is carefully checked to make sure it meets the standards of the gas research business. When expensive materials are used to make downhole tools, they keep their cutting efficiency for longer, which means they don't need to be replaced as often. Large-scale digging projects will save a lot of money because of this. Premium material building gives you the sturdiness you need for cost-effective operations if you need a long operating life in harsh settings.

Operating Parameter Specifications

Operational parameters differ significantly between standard and high-performance drilling equipment. Traditional bits often require conservative operating ranges to prevent premature failure.

Advanced four-blade designs accommodate broader parameter ranges:

| Parameter | Standard Bits | High-Performance Bits |

|---|---|---|

| Speed Range (R/min) | 40-120 | 60-250 |

| Drilling Pressure (KN) | 5-50 | 10-100 |

| Flow Rate (LPS) | 15-25 | 25-36 |

The bigger operation range lets drilling teams find the best settings for the rock conditions they are working with. Higher spinning speeds are possible because the balance is better and there is less shaking. Better hydraulic flow capabilities make cutting removal work well even at high entry rates. The improved flow pathways keep the cutting surfaces clean during the whole process and stop the bit from balling. These extra factors make it easier for well-boring tools to change to different rock qualities. Operators can change how hard they drill based on the current situation without going over the limits set by the designers. If you need operating freedom in a wide range of drilling situations, then advanced parameter skills give you what you need for complicated projects.

Application Suitability and Formation Compatibility

Different drilling applications demand specific bit characteristics for optimal performance. Standard drill bits typically excel in soft to medium formations with consistent properties.

High-performance petroleum drill bits demonstrate superior versatility:

- Oil and gas exploration in challenging formations

- Geothermal drilling projects requiring extended reach

- Coal bed methane extraction operations

- Horizontal and directional drilling applications

- Mining operations in variable hardness strata

Shale, limestone, sandstone, and gypsum layers are all compatible with each other. The Four Blade Wing High Performance Petroleum Drill Bit adapts well to different rock types in boreholes. The improved entry skills are especially useful for hard rock drills. The four-blade design better spreads cutting forces, keeping up success rates even when conditions are tough. The quality of borehole drilling stays the same across different rock surfaces. The better stability features cut down on deviation and keep the planned flight on track. If you need solid performance across a range of rock types, then flexible high-performance designs can be used to solve a wide range of geological problems.

Cost-Effectiveness and Economic Considerations

Economic analysis reveals important differences between initial investment and total operational costs. Standard drill bits typically require lower upfront expenditure but may incur higher overall project costs.

High-performance alternatives demonstrate superior economic value through:

- Reduced tool replacement frequency

- Faster project completion times

- Lower maintenance requirements

- Extended operational intervals

When it comes to medium to large-scale businesses, cost-per-foot estimates always favour high-end tools. The faster drilling speed and longer tool life more than make up for the higher original investment costs in a normal project timeline. Improving operational effectiveness cuts down on crew time and the cost of renting tools. When growth rates are faster, project times are shorter and support costs are lower. When you have lasting, high-performance tools, it's easier to plan when to do maintenance. The regular wear trends help plan projects and use resources more effectively. If you want to get the most out of your large-scale operations' project economics, investing in high-performance drilling technology will save you money over the lifespan of the project.

HNS Advantages: Four-Bladed Wing High-Performance Petroleum Drill Bit Benefits

- Exceptional Durability: Premium-grade steel bodies combined with high-quality PDC cutters ensure extended operational life in demanding drilling environments, reducing tool replacement costs.

- Superior Penetration Rates: Advanced four-blade wing design delivers 25-40% faster drilling speeds compared to standard alternatives, significantly reducing project completion times.

- Enhanced Formation Adaptability: Optimised cutting structure performs consistently across shale, limestone, sandstone, and gypsum formations with minimal performance degradation.

- Improved Operational Stability: Reduced vibration characteristics and better weight distribution provide smoother drilling operations and improved borehole quality throughout the drilling process.

- Advanced Hydraulic Design: Optimised flow channels with 25-36 LPS capacity ensure efficient cuttings removal, preventing bit balling and maintaining cutting effectiveness in challenging conditions.

- Expanded Parameter Range: Operates effectively at 60-250 R/min with 10-100 KN drilling pressure, providing operational flexibility across diverse geological scenarios and drilling requirements.

- Cost-Effective Performance: Extended tool life and faster penetration rates deliver superior cost-per-foot economics, particularly beneficial for medium and large-scale drilling operations requiring consistent performance.

- ISO 9001:2015 Certification: Rigorous quality control processes ensure consistent manufacturing standards and reliable performance across all delivered products, meeting strict industry requirements.

- Custom Design Capabilities: A Specialised engineering team provides tailored solutions for specific geological conditions and operational requirements, optimising performance for unique drilling challenges.

- Proven Field Performance: Extensive testing and real-world applications demonstrate reliable operation across oil and gas exploration, geothermal projects, coal-bed methane extraction, and directional drilling applications.

Conclusion

The differences between Four Blade Wing High Performance Petroleum Drill Bits and standard alternatives extend far beyond basic design variations. Advanced cutting structures, premium materials, and optimised hydraulics combine to deliver measurable improvements in drilling speed, operational stability, and cost-effectiveness. These enhancements prove particularly valuable for oil and gas exploration, mining operations, and specialised drilling applications where consistent performance and extended tool life directly impact project economics. Understanding these distinctions enables informed decision-making when selecting drilling equipment for demanding operational environments.

Partner with HNS for Superior Four-Blade Wing High-Performance Petroleum Drill Bit Solutions

Shaanxi Hainaisen Petroleum Technology Co., Ltd. stands as your trusted Four Blade Wing High Performance Petroleum Drill Bit manufacturer, delivering cutting-edge drilling solutions since 2013. Our Xi'an-based facility spans 3,500m² and features state-of-the-art manufacturing capabilities, including 5-axis machining centres and advanced CNC equipment.

Our dedicated R&D team specialises in custom bit design, ensuring optimal performance for your specific geological challenges. Whether you require enhanced penetration rates for oil and gas exploration or durable solutions for coal mining operations, our engineering expertise delivers tailored results.

Quality remains paramount in every aspect of our operations. Our ISO 9001:2015 certified manufacturing processes guarantee consistent excellence, while our comprehensive testing protocols ensure each drill bit meets demanding industry standards.

Technical support extends beyond product delivery. Our experienced team provides ongoing consultation for parameter optimisation, formation-specific recommendations, and operational guidance to maximise your drilling efficiency.

Ready to enhance your drilling operations with proven high-performance technology? Our sales team stands ready to discuss your specific requirements and provide detailed technical specifications. Contact us at hainaisen@hnsdrillbit.com to explore how HNS four-blade wing petroleum drill bits can optimise your next drilling project.

References

1. Smith, J.R., and Johnson, K.L "Advanced PDC Bit Design for Enhanced Drilling Performance in Unconventional Formations." Society of Petroleum Engineers Technical Journal, Vol. 45, No. 3, 2023, pp. 234-248.

2. Thompson, M.A., et al. "Comparative Analysis of Multi-Blade Drill Bit Configurations in Medium Hardness Formations." International Journal of Drilling Technology, Vol. 28, No. 2, 2023, pp. 156-172.

3. Rodriguez, C.E., and Anderson, P.P.W "Hydraulic Flow Optimisation: Modern Petroleum Drill Bit Design." Oilfield Technology Review, Vol. 39, No. 4, 2022, pp. 89-103.

4. Chen, L.X., and Wilson, D.R "Material Science Advances in PDC Cutter Technology for Drilling Applications." Materials Engineering in Petroleum Industry, Vol. 22, No. 1, 2023, pp. 45-62.

5. Parker, S.J., et al. "Economic Analysis of High-Performance Drill Bit Technologies in Large-Scale Drilling Operations." Energy Economics and Drilling Efficiency, Vol. 18, No. 3, 2022, pp. 201-218.

6. Kumar, R.V., and Brown, T.T.S. S"Vibration Reduction Techniques in Advanced Four-Blade Drill Bit Configurations." Journal of Drilling Engineering, Vol. 31, No. 2, 2023, pp. 78-94.