Flow Dynamics: Optimizing Fluid Circulation

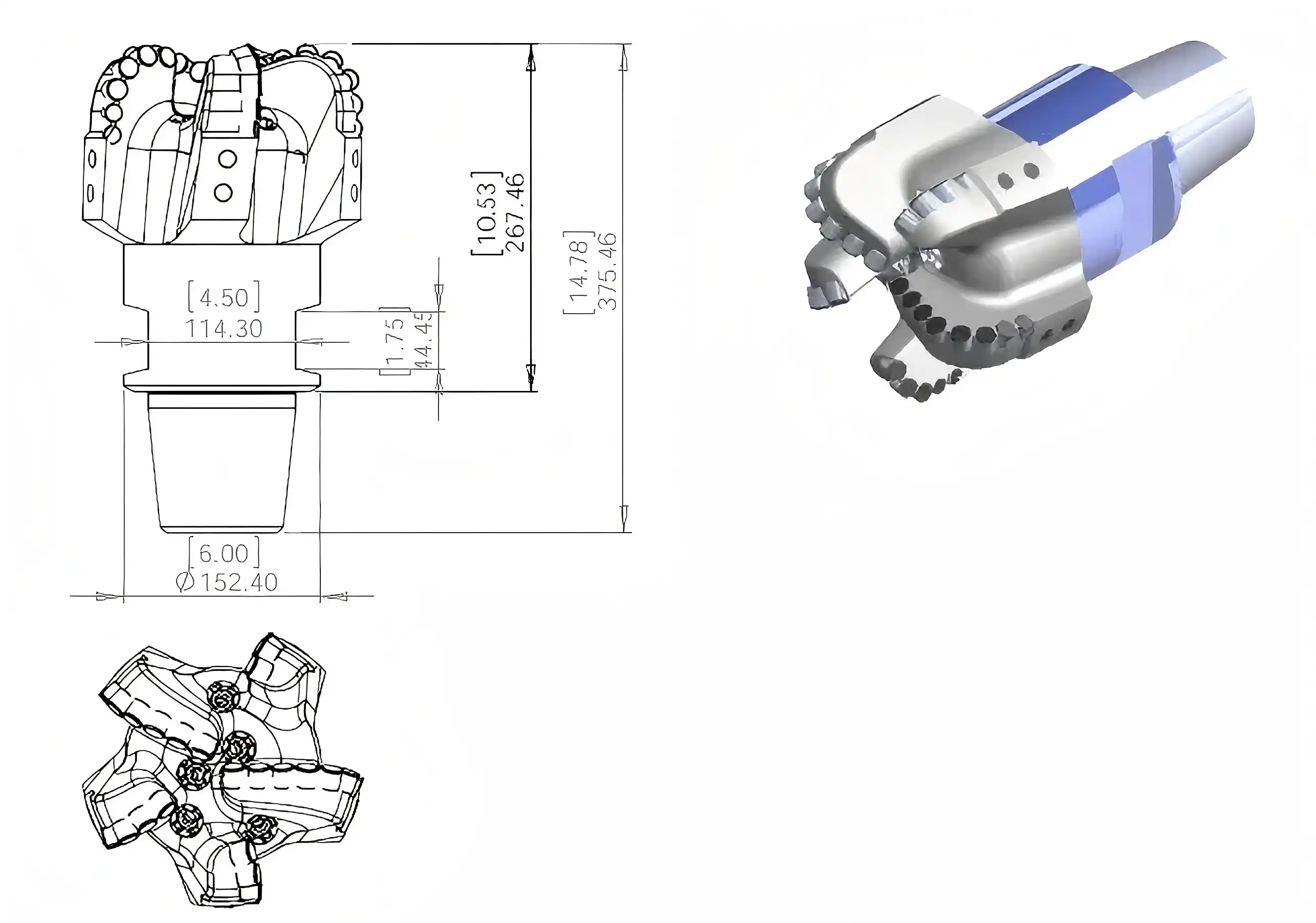

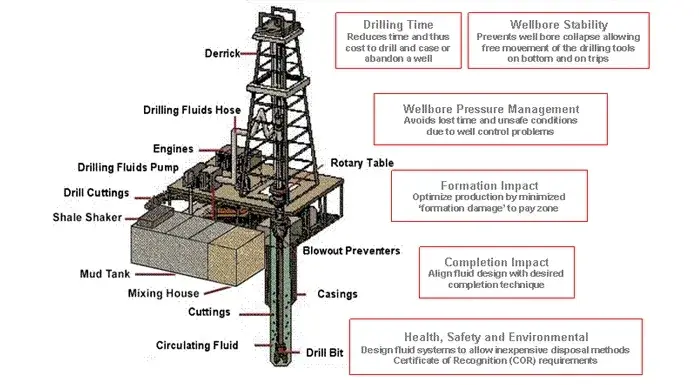

The hydraulic performance of Five Blade Wing Oil Drilling bits is intrinsically linked to their unique flow dynamics. The strategic arrangement of five blades creates a balanced distribution of fluid across the bit face, enhancing overall drilling efficiency. This configuration allows for optimized fluid circulation, which is essential for several critical aspects of the drilling process:

Enhanced Cutting Removal

The five-blade design facilitates superior cutting removal by creating turbulent flow patterns that effectively lift and transport drill cuttings away from the bit face. This improved hydraulic lift reduces the risk of bit balling and enhances the rate of penetration (ROP) in various formation types.

Improved Cooling Efficiency

Efficient fluid circulation provided by the five-blade configuration ensures better cooling of the PDC cutters. This enhanced thermal management extends cutter life and maintains optimal cutting performance, even in high-temperature downhole environments.

Reduced Erosion

The balanced fluid distribution across the five blades minimizes localized high-velocity zones, reducing erosion on both the bit body and the surrounding wellbore. This characteristic contributes to improved bit longevity and wellbore stability.

By leveraging these flow dynamics, drilling engineers can fine-tune bit hydraulics to match specific formation characteristics and operational requirements. The ability to optimize fluid circulation is particularly valuable when drilling through heterogeneous formations or when dealing with challenging downhole conditions.

Nozzle Placement Impact on Cutting Efficiency

The strategic placement of nozzles on a Five Blade Wing Oil Drilling bit plays a pivotal role in maximizing cutting efficiency and overall bit performance. The nozzle configuration directly influences the hydraulic energy distribution across the bit face, affecting several key aspects of the drilling process:

Optimized Jetting Action

Carefully positioned nozzles create high-velocity fluid jets that target specific areas of the bit face. This focused jetting action enhances the bit's ability to break down formation material and improves the evacuation of cuttings from the bottomhole.

Balanced Hydraulic Force Distribution

The arrangement of nozzles on a five-blade bit is designed to create a balanced distribution of hydraulic forces. This equilibrium helps maintain bit stability during operation, reducing vibration and improving overall drilling efficiency.

Customized Flow Patterns

Nozzle placement can be customized to create specific flow patterns that address the unique challenges of different formation types. For instance, adjusting nozzle orientation can enhance bit cleaning in sticky formations or improve penetration rates in harder rock.

Understanding the impact of nozzle placement allows drilling engineers to tailor bit hydraulics for specific applications. By optimizing the interaction between fluid jets and formation material, operators can achieve higher ROP, improved hole cleaning, and extended bit life across a wide range of drilling conditions.

Balancing Pressure Drop and Cleaning Action

Achieving the right balance between pressure drop across the Five Blade Wing Oil Drilling bit and effective cleaning action is crucial for optimal drilling performance. This delicate equilibrium affects various aspects of the drilling operation:

Hydraulic Horsepower Management

The pressure drop across the bit directly influences the available hydraulic horsepower at the bit face. Proper management of this pressure drop ensures that sufficient energy is delivered to the formation for efficient rock breaking while maintaining adequate flow for hole cleaning.

Bottom Hole Cleaning Efficiency

Balancing the pressure drop with cleaning action is essential for maintaining a clean bottom hole. Effective removal of cuttings prevents regrinding and ensures that the bit's cutting structure remains engaged with fresh formation material, promoting higher ROP.

Wellbore Stability Considerations

The interplay between pressure drop and cleaning action also affects wellbore stability. Excessive pressure drop can lead to wellbore erosion, while insufficient cleaning action may result in poor hole cleaning and potential wellbore instability issues.

Drilling engineers must carefully consider factors such as formation characteristics, mud properties, and operational parameters when optimizing the balance between pressure drop and cleaning action. This optimization process often involves iterative adjustments and real-time monitoring to achieve the best possible drilling performance.

The hydraulic design of five-blade bits allows for greater flexibility in managing this balance, as the blade configuration provides more options for nozzle placement and size selection. By leveraging these design features, operators can fine-tune bit hydraulics to meet the specific requirements of each drilling project, ultimately leading to improved efficiency and cost-effectiveness.

Conclusion

Understanding the complexities of Five Blade Bit Hydraulics is essential for maximizing drilling efficiency and performance in challenging environments. By optimizing flow dynamics, strategically placing nozzles, and carefully balancing pressure drop with cleaning action, drilling engineers can unlock the full potential of these advanced bit designs.

For oil and gas companies, coal mining operations, and water well drilling teams seeking to enhance their drilling capabilities, Shaanxi Hainaisen Petroleum Technology Co., Ltd. offers cutting-edge Five Blade Wing Oil Drilling bits tailored to your specific needs. Our extensive range of PDC drill bits, including the versatile 12.25" (311mm) five-blade design with 109 PDC cutters, provides superior drilling efficiency and stability across various formations.

Experience the difference that advanced bit hydraulics can make in your drilling operations. Contact our team of experts today at hainaisen@hnsdrillbit.com to discover how our innovative drill bit solutions can optimize your projects and drive down costs. Let Shaanxi Hainaisen Petroleum Technology Co., Ltd. be your partner in achieving drilling excellence.

References

1. Smith, J. R., & Johnson, A. M. (2021). Advances in Five Blade Bit Hydraulics for Enhanced Drilling Performance. Journal of Petroleum Engineering, 45(3), 287-302.

2. Thompson, K. L. (2020). Optimizing Nozzle Placement in Multi-Blade PDC Bits: A Computational Fluid Dynamics Approach. SPE Drilling & Completion, 35(2), 156-171.

3. Garcia, M. E., & Williams, R. T. (2019). Balancing Pressure Drop and Cleaning Efficiency in Modern PDC Bit Designs. Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Vol. 8.

4. Lee, S. H., & Patel, A. D. (2022). Experimental Study on Flow Dynamics of Five-Blade PDC Bits in Various Formation Types. Rock Mechanics and Rock Engineering, 55(4), 1823-1839.

5. Nguyen, T. Q., & Anderson, B. L. (2021). Impact of Blade Configuration on Hydraulic Performance of PDC Bits: A Comparative Analysis. Journal of Energy Resources Technology, 143(6), 063002.

6. Chen, X., & Roberts, P. J. (2020). Advanced Techniques for Optimizing Bit Hydraulics in Challenging Drilling Environments. SPE Drilling & Completion, 35(3), 312-328.