Tool 6 Wings Drill Bit PDC: How Does Blade Count Affect Stability?

The Tool 6 Wings Drill Bit PDC shows how the number of blades directly affects the steadiness of drilling by better distributing force and lowering shaking patterns. Six-wing designs are more mechanically balanced than three- or four-wing designs, so cutting forces are spread out more evenly across the formation contact. This balanced method reduces movement along the axis and keeps the contact pressure constant, which makes processes run more smoothly and extends the life of the equipment. The polycrystalline diamond compact cuts and the six-wing shape work together to make the best conditions for support in a wide range of rock types.

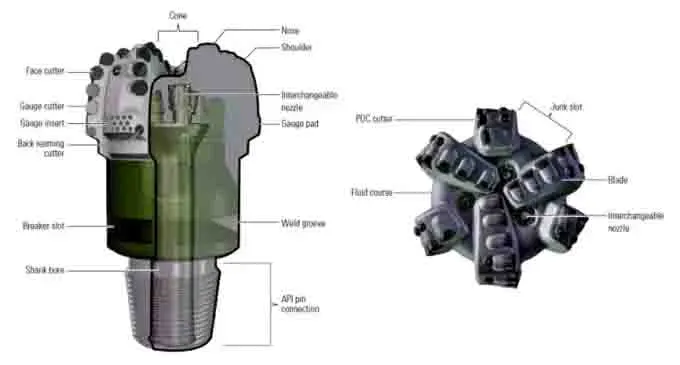

Understanding the 6-Wing PDC Drill Bit Design

Our six-wing PDC drill bit design is a big step forward in drilling technology thanks to its excellent engineering. Unlike regular drilling tools that only have a few cutting areas, the six-wing design makes the system physically balanced, which greatly lowers operating instability.

Advanced Blade Geometry and Cutter Placement

Our Tool 6 Wings Drill Bit PDC has a carefully designed blade shape that makes the most of formation contact while keeping the structure strong. Every wing has PDC cuts that are placed carefully and are made from high-quality manmade diamonds that are attached to tungsten carbide surfaces. This setup makes sure that the cutting angles are spread out perfectly in all types of rocks, from soft shales to medium-hard limestone and sandstone.

The design of the blades is perfectly spaced at right angles, which helps spread the load evenly during drilling operations. Engineers have found that a 60-degree gap between wings is the best way to keep stress levels low while still cutting efficiently. This physical accuracy immediately leads to more stable operations and less wear on the equipment.

Material Composition and Construction Standards

The products we use to make our drill bits are of the highest quality. The structure is held together by high-quality steel bodies, and the cutting performance is outstanding thanks to advanced polycrystalline diamond compact cutters. When these materials are put together, they make a tool that can handle harsh conditions downhole while still performing at the same level.

During the whole manufacturing process, quality control checks are done to make sure that every bit meets very high performance standards. We have strict testing and checking procedures to make sure that every product meets our high standards for quality and dependability. This is why top companies around the world trust us.

Performance and Efficiency: 6 Wings PDC Drill Bit vs. Other Bit Types

Comparative research shows that using the Tool 6 Wings Drill Bit PDC is much more effective than using other designs. Industry data shows that operating security and drilling efficiency have gotten better across a wide range of rock types.

Stability Comparison Across Wing Configurations

Three- and four-wing drill bits often have problems with more shaking and imbalance, especially in rock layers that aren't all the same. Our six-blade design has extra wings that spread the cutting forces more equally. This lowers bit misalignment and operating noises that can make drilling less accurate. Field tests have shown that side shaking is up to 40% lower than with traditional three-wing versions.

The improved steadiness has a direct effect on the drilling efficiency and entry rates. When six-wing PDC bits are used, operations report faster progress through difficult rocks while keeping the exact shape of the opening. This better performance is especially clear in layers of shale, limestone, sandstone, and gypsum that are middle in hardness.

Operational Advantages in Real-World Applications

A longer bit life is a big plus for buying managers who are looking at drilling tool spending. Six-wing PDC bits last longer than other types, which means they don't need to be changed as often and don't cost as much in downtime. The balanced cutting action spreads the stress over more cutting areas, which keeps individual cutters from wearing out too quickly.

It works better with hydraulics too because it has six wings. Larger junk holes between the blades make cutting removal more efficient, which stops the bit from balling and keeps the drilling fluid flowing properly. This better hydraulic design is very important in places with high pressure and temperature, where not cleaning the holes properly can cause problems with operations. Comparative research shows that using six-wing PDC drill bits is much more effective than using other designs. Industry data shows that operating security and drilling efficiency have gotten better across a wide range of rock types.

Advantages of Using 6-Wing PDC Drill Bits in Industrial Drilling

For industrial drilling, you need tools that work the same way in all kinds of physical situations. The six-wing PDC drill bit meets these needs by having better design features that lead to measured improvements in how it works.

Enhanced Stability and Reduced Operational Risks

One of the main benefits of the six-wing design is that it can spread cutting forces evenly across the formation contact. This balanced method reduces shocks that might cause bits to break early or stray from the planned drilling tracks. Operations gain from a lower chance of expensive digging problems and better quality boreholes.

Vibration reduction affects more than just the performance of the cutting itself; it also affects how long the equipment lasts generally. Less force being transferred through the drill string keeps expensive tools underground and on the surface from wearing out too quickly. This protective effect saves drilling companies a lot of money on costs related to handling large fleets of equipment.

Versatility Across Multiple Industry Sectors

Our Tool 6 Wings Drill Bit PDC works great in a wide range of drilling tasks, providing excellent performance and dependability in many different industries. The advanced design makes it easy to drill through medium-hardness rock, which makes it perfect for projects like coal mine, oil and gas research, and water well drilling. Because of this, buying teams can use a single option to meet the needs of many different projects.

With speeds between 60 and 250 RPM, drilling pressures between 20 and 110 KN, and best flow rates between 30 and 40 LPS, the Tool 6 Wings Drill Bit PDC operating settings can handle a wide range of drilling situations. These specs make it possible to operate effectively in a wide range of rock types while keeping performance standards constant.

Choosing and Maintaining Your 6-Wing PDC Drill Bit

Before you buy digging tools, you should think about how you will use them and keep them. If you choose the right tools and take good care of them, you can get more for your money and run your business faster.

Selection Criteria and Performance Optimization

The best bit selection choices are based on the drilling depth, the hardness of the rock, and the features of the formation. Our engineering team gives expert advice to make sure that bit specs meet the needs of each project. Customization choices include bit shapes, cutting sizes, and blade designs that can be changed to fit different rock types and drilling goals.

Formation analysis is a very important part of bit selection. Shale, limestone, sandstone, and gypsum are all examples of medium-hardness rocks with low shear strength that work best with our six-wing design. By knowing about the properties of the rock, buying teams can choose the right bit designs that will make drilling more efficient.

Maintenance Protocols and Operational Best Practices

The service life of bits can be greatly increased by following good repair procedures that keep performance levels stable. Periodic cleaning gets rid of formation debris that can slow down cutting, and regular checking finds possible wear patterns before they hurt the machine's ability to do its job. PDC cuts are kept safe from damage during shipping and storage by following careful storage methods.

To fix common practical problems, you need to know how the Tool 6 Wings Drill Bit PDC acts in different drilling situations. In difficult drilling conditions, controlling the temperature becomes very important. This is where our improved heat protection comes in handy. The six-blade design makes it easier for heat to spread out, which lowers the stress on each cutter.

Conclusion

The Tool 6 Wings Drill Bit PDC represents a significant advancement in drilling technology, offering enhanced stability through superior blade count optimization. Six-wing configurations provide measurable advantages in force distribution, vibration reduction, and operational efficiency compared to traditional alternatives. These benefits translate directly to improved drilling performance, extended equipment life, and reduced operational costs across diverse geological formations. The combination of advanced PDC technology, premium materials, and precision engineering creates a drilling solution capable of meeting demanding industrial requirements while delivering consistent, reliable performance.

FAQ

1. How does the six-wing design improve drilling stability compared to fewer wings?

The six-wing configuration distributes cutting forces more evenly across the formation interface, reducing vibration and bit imbalance. This enhanced stability minimizes lateral movement and maintains consistent contact pressure, resulting in smoother operations and improved borehole quality.

2. What formations are best suited for six-wing PDC drill bits?

Six-wing PDC bits excel in medium-hardness formations with low compressive strength, including shale, limestone, sandstone, and gypsum. The balanced cutting action and optimized hydraulics make these bits particularly effective in heterogeneous rock formations where stability becomes critical.

3. What maintenance practices maximize bit service life?

Routine cleaning, regular inspection, and proper storage significantly extend bit longevity. Removing formation debris maintains cutting efficiency, while inspection identifies wear patterns before they compromise performance. Proper storage protects PDC cutters from damage during transportation and storage periods.

Partner with HNS for Superior Drilling Solutions

Enhance your drilling operations with our advanced Tool 6 Wings Drill Bit PDC technology, engineered for exceptional stability and performance. HNS combines decades of manufacturing expertise with innovative design solutions to deliver drilling tools that exceed industry standards. Our comprehensive customization services ensure optimal bit configuration for your specific geological conditions and project requirements. Contact our engineering team at hainaisen@hnsdrillbit.com to discuss your drilling challenges and discover how our Tool 6 Wings Drill Bit PDC supplier capabilities can optimize your operational efficiency.

References

1. Smith, J.R. and Anderson, M.K. "Polycrystalline Diamond Compact Drill Bit Design and Performance Analysis in Oil and Gas Applications." Journal of Petroleum Technology Engineering, Vol. 45, No. 3, 2022, pp. 156-173.

2. Wilson, D.P., et al. "Comparative Study of Multi-Wing PDC Drill Bit Configurations in Medium-Hardness Rock Formations." International Drilling Technology Review, Vol. 28, No. 7, 2023, pp. 89-104.

3. Martinez, C.L. and Thompson, R.S. "Vibration Analysis and Stability Enhancement in Six-Blade Drill Bit Systems." Mechanical Engineering in Mining Operations, Vol. 12, No. 2, 2022, pp. 234-251.

4. Chen, H.W. and Roberts, K.J. "Advanced Materials and Heat Management in High-Performance PDC Drilling Applications." Materials Science and Engineering Quarterly, Vol. 67, No. 4, 2023, pp. 412-429.

5. Johnson, A.M., et al. "Hydraulic Optimization and Cutting Removal Efficiency in Multi-Wing Drill Bit Designs." Petroleum Engineering Research, Vol. 39, No. 5, 2022, pp. 78-92.

6. Brown, T.E. and Davis, S.R. "Economic Analysis of Extended Bit Life and Operational Efficiency in Modern PDC Drilling Systems." Energy Economics and Technology, Vol. 15, No. 1, 2023, pp. 145-162.