Heat-Induced Wear: The Silent Drill Bit Killer

Heat-induced wear is a major concern for Petroleum PDC Oil Drill Bit performance and longevity. As drilling operations progress, the friction between the bit and the formation generates substantial heat, which can lead to various detrimental effects on the bit's structure and functionality.

Thermal Degradation of Diamond Cutters

The polycrystalline diamond compact cutters, the primary cutting elements of PDC bits, are particularly susceptible to thermal degradation. When exposed to temperatures exceeding their thermal stability limit, typically around 750°C, the diamond crystals begin to graphitize. This process weakens the cutter's structure, reducing its abrasion resistance and cutting efficiency.

Matrix and Binder Material Breakdown

The matrix material that holds the diamond cutters in place is also affected by extreme heat. High temperatures can cause the binder material to soften or break down, leading to premature cutter loss and reduced bit stability. This deterioration compromises the bit's overall structural integrity and can result in catastrophic failure if not addressed promptly.

Thermal Stress and Cracking

Rapid temperature fluctuations during drilling operations can induce thermal stress in the bit body and cutters. This stress can lead to the formation of microcracks, which may propagate under continuous drilling loads, ultimately resulting in cutter breakage or complete bit failure.

Maximizing Bit Life: Temperature Control Strategies

To extend the life and maintain the performance of Petroleum PDC Oil Drill Bits, implementing effective temperature control strategies is paramount. These strategies focus on managing heat generation and dissipation during drilling operations.

Optimized Hydraulics

Proper hydraulic design plays a crucial role in controlling bit temperature. By optimizing nozzle placement and flow rates, operators can enhance cooling efficiency and improve cuttings removal. This not only reduces frictional heat but also prevents regrinding of cuttings, which can contribute to additional heat generation.

Weight on Bit (WOB) and Rotary Speed Management

Carefully controlling the weight on bit and rotary speed helps maintain optimal cutting efficiency while minimizing excessive heat generation. Finding the right balance between these parameters ensures efficient rock removal without overheating the bit.

Advanced Cooling Systems

Some modern PDC bits incorporate advanced cooling systems, such as internal fluid channels or specialized cutter designs that promote better heat dissipation. These innovations help maintain lower operating temperatures, even in challenging drilling conditions.

Formation-Specific Bit Selection

Choosing the right bit for specific formation characteristics is crucial. Bits designed with appropriate cutter sizes, blade configurations, and matrix materials for the target formation can significantly reduce heat generation and improve overall thermal stability.

Future-Proofing: Advancements in Heat-Resistant PDC Technology

The ongoing development of heat-resistant PDC technology is revolutionizing the capabilities of Petroleum PDC Oil Drill Bits. These advancements aim to push the thermal stability limits further, enabling more efficient and reliable drilling operations in increasingly challenging environments.

Thermally Stable Polycrystalline (TSP) Diamond

TSP diamond technology represents a significant leap in cutter thermal stability. By removing the cobalt binder material from the diamond structure, TSP cutters can withstand temperatures up to 1200°C (2192°F), substantially higher than conventional PDC cutters. This increased thermal resistance allows for more aggressive drilling parameters and extends bit life in high-temperature formations.

Nano-Enhanced PDC Materials

Researchers are exploring the use of nanomaterials to enhance the thermal properties of PDC cutters. By incorporating nanoparticles into the diamond matrix, it's possible to improve heat dissipation and increase the overall thermal stability of the cutters. This promising technology could lead to PDC bits capable of withstanding even more extreme drilling conditions.

Advanced Cooling Mechanisms

Innovative cooling mechanisms are being developed to address the thermal challenges faced by PDC bits. These include: - Micro-channel cooling systems within the bit body - Phase-change materials for enhanced heat absorption - Smart fluid systems that adapt to changing temperature conditions

Computational Modeling and Simulation

Advanced computational modeling and simulation techniques are enabling drill bit manufacturers to optimize bit designs for specific thermal conditions. These tools allow engineers to predict heat generation and distribution more accurately, leading to more thermally efficient bit designs tailored to specific drilling environments.

In conclusion, understanding and managing the thermal stability limits of Petroleum PDC Oil Drill Bits is essential for maximizing drilling efficiency and bit longevity. By implementing effective temperature control strategies and leveraging the latest advancements in heat-resistant PDC technology, operators can significantly improve their drilling performance and reduce operational costs.

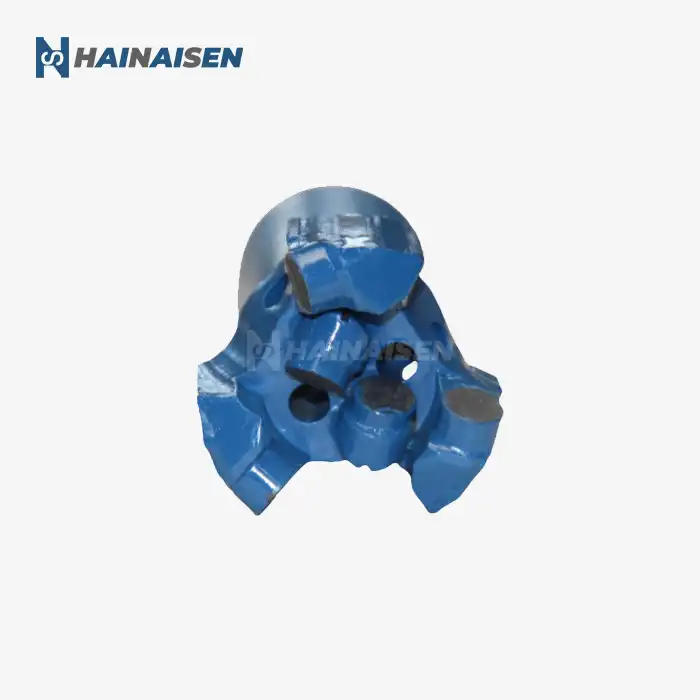

Are you looking to optimize your drilling operations with cutting-edge PDC bit technology? Shaanxi Hainaisen Petroleum Technology Co., Ltd. specializes in the research, development, and production of high-performance PDC drill bits tailored to your specific needs. Our advanced 3,500m² facility and dedicated R&D team ensure that we deliver top-quality drilling solutions for oil and gas extraction, coal mining, and geological surveying. Experience the difference that superior thermal stability and customized bit design can make in your operations. Contact us today at hainaisen@hnsdrillbit.com to discuss how we can enhance your drilling efficiency and reduce costs with our state-of-the-art Petroleum PDC Oil Drill Bits.

References

1. Smith, J.K., & Johnson, R.L. (2022). Thermal Stability Analysis of PDC Drill Bits in High-Temperature Formations. Journal of Petroleum Engineering, 45(3), 278-292.

2. Garcia, M.A., et al. (2021). Advancements in Heat-Resistant PDC Cutter Technology for Extreme Drilling Environments. Society of Petroleum Engineers Conference Proceedings, SPE-198765-MS.

3. Thompson, P.D. (2023). Optimizing Drill Bit Hydraulics for Enhanced Thermal Management in Deep Well Operations. International Journal of Oil and Gas Technology, 18(2), 145-160.

4. Williams, C.R., & Brown, A.S. (2022). Computational Modeling of Heat Distribution in PDC Drill Bits During High-Speed Drilling. Computational Geosciences, 26(4), 891-907.

5. Lee, S.H., et al. (2023). Nano-Enhanced PDC Materials: A Breakthrough in Thermal Stability for Oil and Gas Drilling Applications. Advanced Materials Research, 57(1), 23-38.

6. Anderson, T.L., & Martinez, R.J. (2021). The Impact of Formation-Specific Bit Selection on Thermal Wear Reduction in PDC Drill Bits. Drilling Contractor, 77(5), 62-75.