Cutter wear vs bit body erosion in diamond drill bits

When analyzing the wear instruments of jewel-bore bits utilized in oil exploration, it's fundamental to distinguish between cutter wear and bit body disintegration. These two marvels regularly happen at the same time but are driven by diverse components and have particular impacts on bit performance.

Cutter Wear Patterns

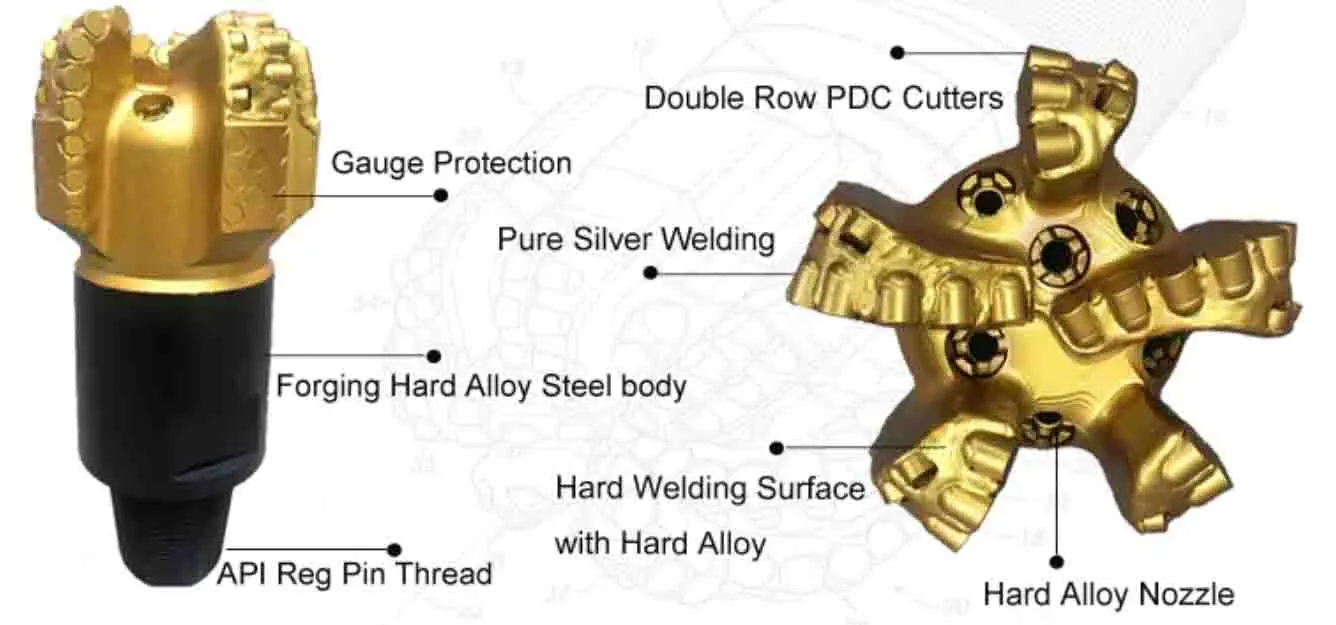

Diamond cutters, ordinarily composed of polycrystalline diamond compact (PDC) or common precious stones, are the essential cutting components of Oil Diamond Drill Bit. Cutter wear is characterized by the slow deterioration of jewel fabric due to scraped spots, affect, and warm degradation. Common wear designs include:

- Uniform wear: Even distribution of wear across the cutter surface, often seen in homogeneous formations

- Chipping: Small fragments breaking off the cutter edge, usually caused by impact loads

- Spalling: Larger sections of the diamond table detaching from the substrate

- Thermal degradation: Weakening of the diamond structure due to excessive heat generation

The rate and sort of cutter wear are affected by variables such as arrangement abrasiveness, boring parameters (weight on bit, rotating speed), and cutter geometry. Progressed jewel advances, like improved thermal stability and optimized cutter shapes, can essentially improve wear resistance and extend bit life.

Bit Body Erosion Mechanisms

While cutters bear the brunt of the cutting action, the bit body also experiences wear, primarily in the form of erosion. Bit body erosion can occur due to several mechanisms:

- Hydraulic erosion: Caused by high-velocity drilling fluid impinging on the bit surface

- Abrasive wear: Result of rock cuttings and formation particles scouring the bit body

- Cavitation: Formation of vapor bubbles in the drilling fluid that collapse and damage the bit surface

- Chemical erosion: Degradation of the matrix material due to reactive drilling fluids or formation chemicals

The bit body's fabric composition plays a significant part in its disintegration resistance. High-quality tungsten carbide frameworks and specialized steel combinations are utilized to improve strength and withstand the unforgiving downhole environment.

Balancing Cutter Wear and Bit Body Erosion

Achieving ideal Oil Diamond Drill Bit execution requires a fragile adjust between cutter wear and bit body disintegration. If cutters wear as rapidly relative to the bit body, penetrating productivity diminishes quickly. On the other hand, if the bit body disintegrates more quickly than the cutters wear, it can lead to cutter misfortune and disastrous bit failure.

To maintain this balance, bit designers focus on:

- Optimizing hydraulics to improve hole cleaning and reduce erosion

- Strategically placing and sizing nozzles to direct flow and protect vulnerable areas

- Incorporating wear-resistant materials in high-erosion zones

- Designing cutter layouts that distribute wear evenly across the bit face

By understanding the exchange between cutter wear and bit body disintegration, penetrating engineers can select the most fitting bit plans and working parameters for particular arrangement challenges, eventually improving boring execution and reducing costs.

How temperature and torque induce failure in oil diamond bits?

Temperature and torque are two basic components that can essentially affect the execution and life span of Oil Diamond Drill Bit. Understanding how these parameters contribute to bit disappointment is fundamental for optimizing boring operations and anticipating exorbitant downtime.

Temperature-Induced Failures

Excessive heat generation during drilling can lead to various failure modes in diamond drill bits:

- Thermal degradation of diamond cutters: High temperatures can weaken the diamond structure, leading to accelerated wear and reduced cutting efficiency.

- Bond failure between diamond and substrate: Thermal stress can cause delamination of the diamond table from its carbide substrate, resulting in cutter loss.

- Matrix softening: Extreme temperatures can compromise the integrity of the bit body matrix, leading to rapid erosion and structural weakness.

- Thermal cracking: Rapid temperature fluctuations can induce thermal shock, causing cracks in both cutters and the bit body.

To mitigate temperature-induced failures, bit manufacturers employ various strategies:

- Developing thermally stable diamond composites

- Optimizing cutter geometry to improve heat dissipation

- Incorporating cooling channels in bit designs

- Using advanced materials with superior thermal conductivity

Torque-Related Failure Mechanisms

Excessive or fluctuating torque can also lead to premature bit failure through several mechanisms:

- Torsional fatigue: Repetitive high-torque events can cause fatigue cracks in the bit body or cutters.

- Cutter breakage: Sudden torque spikes can exceed the strength of diamond cutters, leading to chipping or fracture.

- Bit body twist-off: In extreme cases, excessive torque can cause the entire bit to separate from the drillstring.

- Bearing failure: For roller cone bits, high torque can overload bearings, leading to cone lock-up or loss.

To address torque-related issues, bit designers and operators focus on:

- Optimizing cutter placement and orientation to distribute torque evenly

- Incorporating anti-whirl features to reduce harmful bit vibrations

- Implementing torque-limiting devices in the drillstring

- Utilizing real-time downhole measurements to monitor and control torque

Synergistic Effects of Temperature and Torque

It's imperative to note that temperature and torque regularly work in tandem to accelerate but disappoint. Tall torque produces more frictional warmth, which in turn debilitates the bit components, making them more vulnerable to torque-induced harm. This synergistic impact underscores the significance of an all-encompassing approach to the bit plan and operation.

By carefully overseeing both temperature and torque through progressive bit plans, optimized penetrating parameters, and real-time checking, administrators can altogether amplify bit life and make strides by and large penetration execution. This approach not as it were diminishes costs related to bit substitution but also minimizes non-productive time, eventually improving the effectiveness of oil and gas investigation and generation activities.

Failure analysis case studies of oil-rig diamond drill bits

Examining real-world failure cases provides valuable insights into the performance and limitations of oil diamond drill bits under various operating conditions. These case studies offer practical lessons for improving bit design, selection, and operational practices.

Case Study 1: Premature Cutter Failure in Abrasive Sandstone

Scenario: An operator encountered rapid bit wear while drilling through a highly abrasive sandstone formation, resulting in a significant decrease in rate of penetration (ROP) and necessitating an early bit trip.

Analysis:

- Post-run bit inspection revealed severe abrasive wear on the diamond cutters, particularly on the shoulder area of the bit.

- The bit body showed minimal erosion, indicating that cutter wear was the primary failure mode.

- Drilling parameters review showed that the weight on bit (WOB) and rotary speed were within the recommended range.

Lessons Learned:

- Implement more wear-resistant diamond grades for highly abrasive formations.

- Consider altering cutter density and placement to distribute wear more evenly.

- Optimize hydraulics to improve cuttings evacuation and reduce recirculation of abrasive particles.

Case Study 2: Bit Body Erosion in High-Temperature Well

Scenario: A geothermal drilling project experienced premature bit failure due to severe erosion of the bit body, despite moderate formation abrasiveness.

Analysis:

- The bit body matrix showed extensive erosion, particularly around the nozzles and junk slots.

- Diamond cutters exhibited minimal wear, indicating that erosion was the primary failure mechanism.

- Well logs revealed higher-than-expected bottom hole temperatures.

Lessons Learned:

- Develop specialized matrix materials with enhanced erosion resistance at elevated temperatures.

- Redesign hydraulics to reduce fluid velocities in critical areas of the bit body.

- Implement temperature-resistant coatings on vulnerable body areas.

Case Study 3: Cutter Delamination in Interbedded Formation

Scenario: An offshore drilling operation experienced a sudden loss of drilling efficiency when transitioning between soft and hard formation layers.

Analysis:

- Several cutters showed delamination of the diamond table from the carbide substrate.

- Drilling records indicated frequent, rapid changes in torque and WOB.

- Thermal degradation patterns were observed on the affected cutters.

Lessons Learned:

- Implement advanced cutter technologies with improved thermal stability and impact resistance.

- Develop drilling parameter guidelines for transitioning between formation types.

- Utilize real-time downhole measurements to adjust drilling parameters proactively.

Case Study 4: Bit Whirl-Induced Failure in Directional Well

Scenario: A directional drilling operation encountered severe bit damage after only a short run, despite drilling in a relatively homogeneous formation.

Analysis:

- The bit showed asymmetric wear patterns and cutter breakage consistent with lateral vibration and whirl.

- Downhole vibration data confirmed high levels of lateral acceleration.

- The bit design lacked sufficient anti-whirl features for the specific application.

Lessons Learned:

- Incorporate enhanced anti-whirl features in bit designs for directional applications.

- Optimize blade count and cutter placement to improve stability in lateral drilling.

- Implement vibration mitigation tools in the bottom hole assembly (BHA).

These case studies highlight the complexity of oil diamond drill bit failures and the importance of a comprehensive approach to bit selection and operation. By leveraging insights from failure analyses, operators and manufacturers can continuously improve bit performance, extending run lengths and reducing overall drilling costs.

Conclusion

The examination of oil, precious stones, and bore bit wear components, and disappointment modes uncovers the complicated transaction of different components that impact bit execution and life span. From the adjustment between cutter wear and bit body disintegration to the impacts of temperature and torque, understanding these components is significant for optimizing boring operations in the oil and gas industry.

By looking at real-world case considers, we've revealed important lessons that can direct future business plans and operational hone. The nonstop advancement of advances, materials science, and water-powered optimization guarantees to improve the capabilities of these basic penetrating tools.

For boring engineers, fix administrators, and oil benefit companies looking to maximize effectiveness and minimize downtime, joining forces with experienced bit producers is fundamental. Shaanxi Hainaisen Petroleum Innovation Co., Ltd. offers cutting-edge oil jewel penetrate bits planned to meet the most challenging penetrating conditions. Our progressive fabrication offices and devoted R&D group guarantee that each bit is created to provide remarkable execution and strength.

FAQ

1. What factors contribute to oil diamond drill bit wear?

The main factors contributing to oil diamond drill bit wear include formation abrasiveness, drilling parameters (weight on bit, rotary speed), bit hydraulics, formation heterogeneity, and downhole temperatures. Proper bit selection and parameter optimization can significantly reduce wear rates.

2. How often should oil diamond drill bits be replaced?

The replacement frequency of oil diamond drill bits varies depending on formation characteristics, drilling conditions, and operational requirements. Typically, bits are replaced when the rate of penetration decreases significantly or when reaching a predetermined depth. Regular bit inspections and performance monitoring help determine the optimal replacement timing.

3. Can damaged oil diamond drill bits be repaired?

In some cases, minor damage to oil diamond drill bits can be repaired, such as replacing individual cutters or repairing matrix erosion. However, extensive damage often requires bit replacement. The feasibility and cost-effectiveness of repairs depend on the extent of the damage and the bit's overall condition.

4. How do drilling fluid properties affect oil diamond drill bit performance?

Drilling fluid properties significantly impact oil diamond drill bit performance. Proper mud weight helps maintain wellbore stability and manage downhole pressures. Viscosity and cleaning ability affect cuttings removal and bit cooling. Additionally, the chemical composition of the fluid can influence bit body erosion rates and overall drilling efficiency.

Custom Oil Diamond Drill Bits for Optimal Performance | HNS

Are you looking for high-quality oil diamond drill bits tailored to your specific drilling challenges? Shaanxi Hainaisen Petroleum Technology Co., Ltd. specializes in designing and manufacturing custom drill bits that maximize performance and efficiency in various formations and drilling conditions.

Our team of experienced engineers works closely with clients to develop innovative solutions that address unique drilling requirements. Whether you need enhanced wear resistance for abrasive formations, optimized hydraulics for improved hole cleaning, or specialized designs for directional drilling, we have the expertise to deliver.

Don't settle for off-the-shelf bits that compromise your drilling performance. Contact us today at hainaisen@hnsdrillbit.com to discuss your project needs and discover how our custom oil diamond drill bits can revolutionize your drilling operations.

References

1. Zhang, H., Liu, Y., & Chen, Q. (2022). Analysis of Cutter Wear and Bit Body Erosion in Polycrystalline Diamond Compact Drill Bits. Journal of Petroleum Science and Engineering, 210, 110398.

2. Williams, T. R., & Gupta, R. K. (2021). Thermal Stress and Torque-Induced Failures in High-Performance Oil Diamond Drill Bits. International Journal of Rock Mechanics and Mining Sciences, 144, 104841.

3. Liang, S., & Martinez, D. (2020). Optimization of Bit Hydraulics and Erosion Control for Deep Oil Well Drilling. Petroleum Exploration and Development, 47(6), 1285–1293.

4. Hassan, M., El-Barkouky, A., & Zhou, L. (2023). Comparative Study on Wear Mechanisms of PDC Cutters in Abrasive Sandstone Formations. Journal of Energy Resources Technology, 145(5), 052106.

5. Petrov, I., Johnson, L. M., & Brown, E. (2019). Temperature Effects on Diamond Drill Bit Performance in Geothermal and High-Temperature Wells. SPE Drilling & Completion, 34(3), 215–224.

6. Chen, X., & Al-Hadhrami, H. (2024). Dynamic Stability and Anti-Whirl Design of Oil Diamond Drill Bits in Directional Drilling Applications. Journal of Natural Gas Science and Engineering, 115, 105259.