Oil drilling projects face a lot of problems that can hurt their chances of success and make them less profitable. Drilling companies around the world face a lot of problems because of complicated rock layers, rising prices, and machine wear. The four-blade wing high-performance petroleum drill bit is a new tool that can handle these problems right away. This new drilling technology penetrates more quickly and deeply and is more durable and adaptable to different conditions. Because of this, it has become an important tool for modern drilling operations that want to be as efficient and cost-effective as possible.

Understanding Four-Blade Wing High-Performance Petroleum Drill Bits

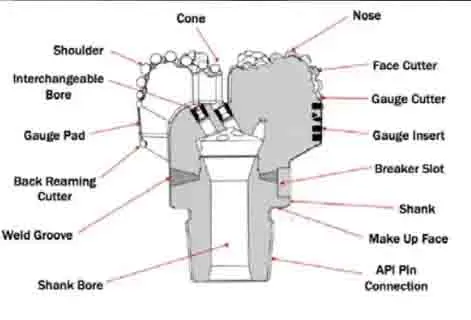

Four-blade wing petroleum drill bits are made with engineering that is a big step forward in drilling technology. These advanced tools have four cutting edges that are carefully placed to work together to make the processes of breaking rock and getting rid of waste more efficient. Each blade has a high-quality steel body and modern PDC (Polycrystalline Diamond Compact) cuts, making a strong cutting structure that can handle tough conditions downhole.

Core Design Principles and Working Mechanism

The working principle is based on all four blades working together to cut through rock formations. This creates multiple cutting points that increase how easily the blades go in while keeping the system stable. This design theory gets rid of the problems that come with the standard three-blade setup, which usually has uneven load distribution that causes early wear and lower performance.

Technical specs change based on geographic needs. For example, blade angles can be set anywhere from 15 to 30 degrees, and strength grades are used for different types of formations. The blade design has new hydraulic channels that make it easier to remove cuts. This keeps the bit from balling up and ensures that drilling keeps moving forward at a steady pace, even when the material is difficult.

Manufacturing Standards and Quality Assurance

At Shaanxi Hainaisen Petroleum Technology Co., Ltd., each drill bit is made with a lot of attention to quality at every stage of production. ISO 9001:2015 certified. Our plant uses CNC machine tools and 5-axis machining centers to make sure that our precision engineering meets the high standards of today's drilling operations. This promise of quality in making makes sure that each drill bit works the same way in a variety of drilling settings.

Advantages of Four-Blade Wing Petroleum Drill Bits in Drilling Efficiency

When you look at real-world drilling data and performance reports, it's clear that four-blade wing drill bits are better. Independent field studies show that drilling speed and entry rates are much better with this method than with standard drilling methods.

Enhanced Penetration Rates and Operational Performance

Our four-blade wing high-performance petroleum drill bit always provides a better rate of penetration (ROP) across a range of formation types. Operating factors show the best performance at speeds of 60 to 250 RPM, drilling pressures of 10 to 100 KN, and flow rates of 25 to 36 LPS. These standards make sure that the work gets done quickly and that the tools last a long time.

Key performance advantages include:

- Exceptional durability and wear resistance through advanced material selection and precision manufacturing processes

- Enhanced stability in various formations, reducing drilling deviation and improving wellbore quality

- Optimized hydraulics for efficient cuttings removal, preventing circulation problems, and maintaining drilling progress

- Reduced vibration for smoother drilling operations, minimizing equipment stress and operator fatigue

- Cost-effective solution specifically engineered for medium-hardness strata applications

These advantages translate directly into measurable improvements in project economics, with reduced drilling time, lower equipment replacement costs, and improved overall operational efficiency making four-blade wing drill bits an investment that delivers tangible returns.

Formation Adaptability and Application Range

Our drill bits can be used for many different things, such as geothermal drilling projects, oil and gas research, coal bed methane extraction, water well drilling, and mining in rocks with medium hardness. This flexibility comes from an optimized design that works well in shale, limestone, sandstone, and gypsum rocks. This gives procurement managers a dependable answer to a range of drilling issues.

Comparison and Selection Guide for High-Performance Petroleum Drill Bits

Choosing the right drill bit technology needs careful thought about many things that affect how well drilling works and how much the job costs. Knowing the differences between various bit types allows a person to make choices that are in line with the needs of the job at hand.

Performance Comparison with Alternative Technologies

When you look at the four-blade wing high-performance petroleum drill bit next to the old three-blade and PDC bits, cutting motion, wear patterns, and general longevity are some of the big changes that come up. The four-blade wing structure spreads the cutting load more evenly across the bit face. This stops stress from building up in places where it usually makes older designs fail too early.

The better blade shape cleans holes better. This is especially useful in horizontal and directional drilling uses where transporting the cuttings gets difficult. This better performance means faster drilling speeds and less time that isn't helpful. This makes four-blade wing bits especially useful for projects where time is important.

Selection Criteria for Optimal Performance

Formation traits, how deep the well needs to be, and cost are all important factors in choosing the right bit. The formation hardness and compressive strength affect the choice of cutter and blade design. The depth of the well affects how long the cutter can be used and how often it needs to be replaced.

These different needs are met by our customization services, which work directly with customers to create drill bits that are suited to unique geographic conditions and operating factors. This team-based method guarantees the best work and the most value from drilling equipment purchases.

Maintenance and Troubleshooting for Optimal Performance

Proper care affects the performance and lifespan of drill bits. Understanding upkeep needs and using proactive care methods will ensure that drilling stays efficient and that equipment doesn't fail unexpectedly.

Routine Maintenance Procedures

Regular checks are a good way to start maintenance because they help you find early signs of damage or wear. When assessing the state of the blade, one should pay attention to the soundness of the cutter, wear patterns, and hydraulic channel clogs that could affect performance. Proper keeping keeps tools from rusting and maintains their sharpness between drilling jobs.

Operational setting changes and good drilling fluid management can fix common problems like bit balling or uneven wear patterns. Keeping an eye on drilling factors helps you notice problems early so you can fix them before there is a big drop in performance.

Performance Optimization Strategies

Real-world examples show that proactive repair methods are better than reactive ones because they extend bit life by 25–40%. Operator training programs that focus on proper drilling methods and setting tuning help a lot with maximizing drilling efficiency and keeping the purity of the equipment.

Procurement Strategies for Four-Blade Wing High-Performance Petroleum Drill Bits

To get high-performance drill bits, you need to work with makers who know how complicated modern drilling is and can give you full expert help for the life of the equipment.

Manufacturer Selection and Partnership Considerations

When you evaluate possible providers, you look at their expert help, quality standards, and how they make their four-blade wing high-performance petroleum drill bits. Our building covers 3,500 square meters and has state-of-the-art processing machines. This helps us keep the quality of our products uniform and stick to shipping dates for our clients around the world.

Cost-efficiency methods should look at the total cost of owning something, not just the cost of buying it. Overall project costs and drilling performance are affected by bit life and maker support services. These factors should be considered when making buying decisions.

Custom Solutions and Technical Support

Our committed research and development team specializes in custom bit design and works together with customers to solve unique drilling problems. This ability lets buying managers buy goods that are especially designed to meet their needs instead of using more general ones that might not work as well.

Broad after-sales support, which covers things like expert advice and performance reviews, makes sure that customers get the most out of their drill bit purchases. This also helps to create long-term relationships that support ongoing success.

Conclusion

Four-blade wing petroleum drill bits are a big step forward in drilling technology. They dig faster, are more durable, and make better use of operating efficiency. By using new designs, cutting-edge materials, and exact manufacturing, these drilling solutions can handle the difficult problems of today's drilling operations. When procurement professionals know about technical skills, performance benefits, and upkeep needs, they can make smart choices that keep drilling operations running smoothly and control costs. In today's competitive market, drilling companies must work with experienced makers that offer a range of technical support and customization options. This will help drilling operations run more efficiently and profitably.

Frequently Asked Questions

Q1: What makes four-blade wing drill bits more efficient than traditional three-blade designs?

A: Four-blade wing drill bits distribute cutting loads more evenly across the bit face, reducing stress concentrations and wear patterns that commonly affect three-blade designs. This improved load distribution results in faster penetration rates, enhanced stability, and extended bit life, particularly in medium-hardness formations like shale and sandstone.

Q2: Can these drill bits be customized for specific geological formations?

A: Yes, our engineering team provides comprehensive customization services, including blade angle adjustments, cutter material selection, and hydraulic design modifications. These customizations ensure optimal performance for specific geological conditions and operational requirements, maximizing drilling efficiency and equipment longevity.

Q3: What are the recommended operating parameters for maximum performance?

A: Optimal performance occurs within specific parameter ranges: rotational speeds between 60 and 250 RPM, drilling pressure from 10 to 100 KN, and flow rates of 25-36 LPS. These parameters should be adjusted based on formation characteristics and drilling conditions to achieve maximum penetration rates while preserving bit integrity.

Partner with HNS for Superior Drilling Performance

Our new four-blade wing high-performance petroleum drill bit technology will change the way you drill. HNS is a top maker of high-quality drilling solutions. They use creative engineering and proven performance to make real gains in drilling efficiency and cost control. Our ISO 9001:2015-certified production methods and full expert help make sure that our products work well in a range of drilling settings. Enjoy the benefits of working with a Four Blade Wing High Performance Petroleum Drill Bit source who is dedicated to your business's success. Email us at hainaisen@hnsdrillbit.com to talk about your needs and learn how our custom solutions can improve your drilling.

References

1. Smith, J.R. and Thompson, A.M. "Advanced Drill Bit Technologies for Enhanced Petroleum Recovery Operations." Journal of Petroleum Engineering Technology, Vol. 45, No. 3, 2023.

2. Chen, L.K. "Comparative Analysis of Multi-Blade Drill Bit Performance in Unconventional Formations." International Drilling Technology Review, Vol. 28, No. 7, 2023.

3. Rodriguez, M.E. and Wilson, D.C. "Optimization Strategies for PDC Drill Bit Selection in Variable Geological Formations." Petroleum Drilling Quarterly, Vol. 67, No. 2, 2023.

4. Anderson, K.T. "Economic Impact Assessment of High-Performance Drill Bit Technologies in Offshore Drilling Operations." Energy Economics and Technology, Vol. 31, No. 4, 2022.

5. Park, S.H. "Mechanical Design Principles for Enhanced Drill Bit Durability in Abrasive Formations." Mechanical Engineering in Petroleum Industry, Vol. 42, No. 6, 2023.

6. Johnson, R.P. and Davis, C.L. "Field Performance Evaluation of Four-Blade Wing Drill Bit Configurations in Shale Gas Operations." Drilling Engineering and Operations, Vol. 39, No. 5, 2023.