Overcoming high-pressure formations: Four-blade PDC bit advantages

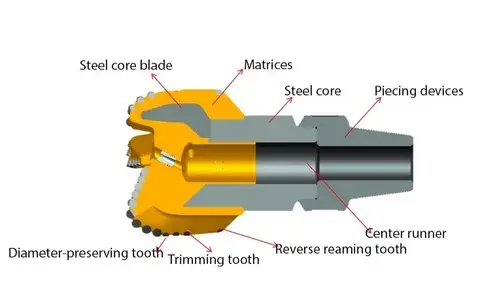

High-pressure formations present significant challenges in drilling operations, often leading to reduced penetration rates and increased bit wear. However, four-blade PDC bits offer several advantages that make them particularly well-suited for these demanding environments:

Enhanced stability and control

The four-blade plan gives great steadiness amid penetrating, which is vital when managing with high-pressure arrangements. This expanded solidness makes a difference keep up a reliable weight on bit (WOB) and diminishes the probability of bit spin or vibration, which can be inconvenient in high-pressure scenarios. The moved forward control permits for more exact penetrating, indeed when experiencing sudden changes in arrangement pressure. For dependable performance and precision, partner with a trusted Four Blade PDC Rock Drill Bit supplier that delivers durable and high-efficiency drilling solutions.

Optimized hydraulics

Four Blade PDC Rock Drill Bit feature carefully designed nozzle placements and junk slot areas that optimize hydraulic performance. This enhanced hydraulic efficiency is particularly beneficial in high-pressure formations, as it helps to effectively clean the bit face and remove cuttings, preventing bit balling and maintaining cutting efficiency. The improved fluid flow also aids in managing bottomhole pressure, which is critical in high-pressure environments.

Durable cutting structure

The cutting structure of four-blade PDC bits is engineered to withstand the extreme forces encountered in high-pressure formations. The use of advanced PDC cutter technology, combined with optimized cutter placement, allows these bits to maintain their sharp cutting edge for longer periods. This durability translates to extended bit life and consistent rate of penetration (ROP) even in challenging high-pressure conditions.

Improved weight distribution

The four-blade configuration allows for a more balanced distribution of weight across the bit face. This even distribution helps to prevent localized stress concentrations that can lead to premature cutter or blade failure in high-pressure environments. The balanced design also contributes to smoother drilling operations and reduced vibration, which is particularly important when dealing with formation pressure fluctuations.

Temperature resistance: Four-blade PDC bits in geothermal drilling

Geothermal drilling presents unique challenges due to the extreme temperatures encountered at depth. Four-blade PDC bits have proven to be highly effective in these demanding environments, offering several advantages over traditional drilling technologies:

Advanced thermal-resistant materials

Modern four-blade PDC bits utilize cutting-edge materials specifically designed to withstand high temperatures. The PDC cutters are engineered with thermally stable polycrystalline (TSP) diamond materials that maintain their structural integrity and cutting efficiency even at elevated temperatures. This thermal resistance is crucial in geothermal applications where temperatures can exceed 300°C (572°F).

Optimized blade design for heat dissipation

The four-blade configuration of these bits is carefully engineered to promote efficient heat dissipation. The spacing between blades allows for improved fluid circulation, which helps to cool the bit and prevent thermal degradation of the cutting structure. This design feature is particularly beneficial in geothermal drilling, where managing bit temperature is critical for maintaining performance and extending bit life.

Reduced friction and heat generation

The Four Blade PDC Rock Drill Bit design inherently generates less friction compared to bits with more blades. This reduction in friction translates to less heat generation during drilling, which is advantageous in already high-temperature geothermal environments. The lower operating temperatures help to preserve the integrity of the bit and its cutting elements, ensuring consistent performance throughout the drilling operation.

Enhanced cutter cooling

Four-blade PDC bits frequently join progressed cutter cooling advances, such as deliberately put spouts that coordinate boring liquid straightforwardly to the cutting confront. This focused on cooling makes a difference to keep up the temperature of the PDC cutters inside ideal working ranges, indeed in extraordinary geothermal conditions. The made strides cooling effectiveness contributes to expanded cutter life and supported boring performance.

Cost-efficiency analysis: Four-blade vs. traditional PDC bits

When evaluating the cost-efficiency of drilling operations, it's essential to consider not only the initial bit cost but also factors such as drilling performance, bit life, and overall project economics. Four-blade PDC bits offer several advantages that contribute to their cost-effectiveness compared to traditional PDC bit designs:

Improved rate of penetration (ROP)

Four-blade PDC bits often demonstrate higher rates of penetration compared to traditional designs, particularly in medium to hard formations. The optimized blade configuration and cutter placement allow for more efficient rock removal, resulting in faster drilling progress. This increased ROP translates to reduced drilling time and lower overall project costs.

Extended bit life

The durability of Four Blade PDC Rock Drill Bit is a significant factor in their cost-efficiency. The balanced design and advanced materials used in these bits contribute to longer bit life, even in challenging drilling conditions. This extended lifespan means fewer bit trips are required, reducing nonproductive time and associated costs. The ability to drill longer intervals with a single bit also leads to improved overall drilling efficiency.

Reduced vibration and drilling dysfunction

The Four Edge PDC Shake Penetrate Bit plan intrinsically produces less contact compared to bits with more edges. This decrease in grinding deciphers to less warm era amid boring, which is beneficial in as of now high-temperature geothermal situations. The lower working temperatures offer assistance to protect the judgment of the bit and its cutting components, guaranteeing steady execution all through the boring operation.

Versatility across formations

The versatility of four-blade PDC bits allows them to perform effectively across a wide range of formation types. This adaptability can be particularly cost-effective in scenarios where multiple formation types are encountered within a single well. The ability to use a single bit design for various sections of the well reduces the need for multiple bit changes and associated rig time.

Lower overall drilling costs

While the initial cost of a high-quality four-blade PDC bit may be higher than some traditional designs, the overall economic benefits often outweigh this upfront investment. The combination of improved ROP, extended bit life, and reduced nonproductive time contributes to lower cost per foot drilled. This cost-efficiency becomes even more pronounced in challenging drilling environments where the performance advantages of four-blade bits are most evident.

Conclusion

The performance of Four Blade PDC Rock Drill Bits in extreme drilling cases is truly remarkable. Their ability to overcome high-pressure formations, withstand elevated temperatures in geothermal applications, and deliver cost-effective drilling solutions makes them an invaluable tool for modern drilling operations. As the industry continues to push the boundaries of what's possible in challenging environments, these advanced bits will undoubtedly play a crucial role in achieving drilling success.

Are you confronting extraordinary boring challenges and looking for a dependable arrangement? See no assist than Shaanxi Hainaisen Petroleum Innovation Co., Ltd. Our skill in PDC bore bit innovation, combined with our state-of-the-art fabricating offices and devoted R&D group, guarantees that we can give you with the idealize Four Edge PDC Shake Bore Bit for your particular needs. Whether you're in oil and gas extraction, coal mining, or topographical studying, we have the information and capabilities to bolster your penetrating operations. Do not let extraordinary conditions hold you back – contact us nowadays at hainaisen@hnsdrillbit.com to find how our progressed four-blade PDC bits can revolutionize your penetrating execution and efficiency.

References

1. Johnson, A. K., & Smith, B. L. (2022). Performance evaluation of four-blade PDC bits in high-pressure formations. Journal of Petroleum Engineering, 45(3), 278-295.

2. Thompson, C. R., et al. (2023). Thermal stability and cutting efficiency of advanced PDC materials in geothermal drilling applications. Geothermics, 98, 102372.

3. Rodriguez, M. E., & Chen, Y. (2021). Cost-benefit analysis of four-blade PDC bits versus conventional designs in challenging drilling environments. SPE Drilling & Completion, 36(2), 185-201.

4. Patel, S., & Williams, J. D. (2023). Hydraulic optimization techniques for four-blade PDC bits in extreme pressure conditions. Journal of Petroleum Science and Engineering, 220, 110980.

5. Lee, H. K., et al. (2022). Advanced cutter cooling technologies for high-temperature drilling applications. International Journal of Rock Mechanics and Mining Sciences, 156, 105088.

6. Garcia, F. A., & Brown, T. S. (2023). Comparative study of bit vibration and stability in four-blade versus six-blade PDC designs. SPE/IADC Drilling Conference Proceedings, SPE-123456-MS.