Geological factors influencing arc angles in rock cutting

Several geological factors play a significant role in determining the optimal arc angles for rock cutting, particularly when using advanced tools like the Four Wing Arc Angle PDC Drill Bit. These factors include:

Rock Hardness and Compressive Strength

The hardness and compressive strength of the rock formation are primary determinants of the appropriate arc angle. Harder rocks with high compressive strengths typically require smaller arc angles to concentrate the cutting force and improve penetration. This allows the bit to effectively fracture and remove the rock material without excessive wear on the cutting elements.

Abrasiveness and Mineral Composition

The abrasiveness of the rock, which is closely related to its mineral composition, affects the choice of arc angle. Highly abrasive formations with minerals like quartz or garnet can cause rapid wear on the cutting elements. In such cases, a slightly larger arc angle may be used to distribute the wear across a larger surface area, thereby extending the bit life.

Rock Texture and Grain Size

The texture and grain size of the rock formation influence how it responds to cutting forces with a Four Wing Arc Angle PDC Drill Bit. Fine-grained rocks often require different arc angles compared to coarse-grained varieties of the same rock type. The texture affects how the rock fractures and breaks under the pressure of the drill bit, which in turn influences the optimal arc angle for efficient cutting.

Stress Conditions and Formation Pressure

The in-situ stress conditions and formation pressure impact the behavior of the rock during drilling. High stress environments may necessitate adjustments to the arc angle to maintain stability and prevent bit damage. Similarly, formations with high pore pressure might require modifications to the arc angle to optimize hydraulics and cuttings removal.

Comparing arc angles: Granite vs. Limestone vs. Basalt

When comparing arc angles for different hard rock formations, it's essential to consider the unique properties of each rock type. Let's examine how arc angles vary for three common hard rock formations: granite, limestone, and basalt, particularly in the context of using a Four Wing Arc Angle PDC Drill Bit.

Granite

Granite is an igneous rock known for its hardness and abrasiveness. When drilling through granite formations:

- Arc Angle Range: Typically 10-15 degrees

- Rationale: The smaller arc angle helps concentrate cutting forces to fracture the hard crystalline structure effectively.

- Considerations: The high quartz content in granite requires durable cutting elements and careful angle selection to minimize wear.

Limestone

Limestone, a sedimentary rock, varies in hardness but is generally softer than granite:

- Arc Angle Range: Usually 15-25 degrees

- Rationale: The larger arc angle allows for more efficient material removal in this relatively softer rock.

- Considerations: Limestone's variable nature may require adjustments based on specific formation characteristics.

Basalt

Basalt, an igneous rock, is known for its hardness and often poses challenges in drilling:

- Arc Angle Range: Generally 12-18 degrees

- Rationale: The moderate arc angle balances the need for concentrated cutting force with heat dissipation in this dense rock.

- Considerations: Basalt's abrasive nature and potential for fracturing require careful optimization of the arc angle.

Comparative Analysis

When comparing these rock types, several factors influence the variation in arc angles:

- Hardness Gradient: Granite typically requires the smallest arc angles due to its extreme hardness, followed by basalt, with limestone allowing for larger angles.

- Abrasiveness Impact: The highly abrasive nature of granite and basalt necessitates careful angle selection to balance cutting efficiency with bit longevity.

- Fracture Mechanics: The way each rock type fractures under stress influences the optimal arc angle. Granite's brittle nature contrasts with limestone's more ductile behavior, affecting angle choice.

- Thermal Considerations: Heat generation during drilling varies among these rock types, with basalt often requiring special attention to heat dissipation through angle optimization.

To get the best drilling results and the longest bit life, it's important to know these changes so you can choose the right Four Wing Arc Angle PDC Drill Bit configuration for each type of rock.

Optimizing drill bit design for varying hard rock formations

It's hard to make the best drill bits for different types of hard rock because you need to know a lot about rock physics, cutting dynamics, and bit hydraulics. When making complex tools like the Four Wing Arc Angle PDC Drill Bit, this efficiency is especially important. Here is a detailed look at the most important things to consider when designing drill bits for different types of hard rock:

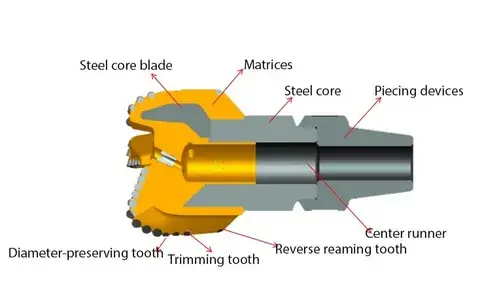

Customizing Cutter Geometry

The geometry of the cutters plays a vital role in drill bit performance across different hard rock formations:

- Back Rake Angle: Adjusting the back rake angle helps balance aggressiveness and durability. Harder formations often require higher back rake angles to protect the cutters.

- Side Rake Angle: Optimizing the side rake angle can improve cutting efficiency and cuttings evacuation, especially in abrasive formations.

- Chamfer Design: The size and angle of the cutter chamfer are tailored to the specific rock properties to enhance impact resistance and cutting efficiency.

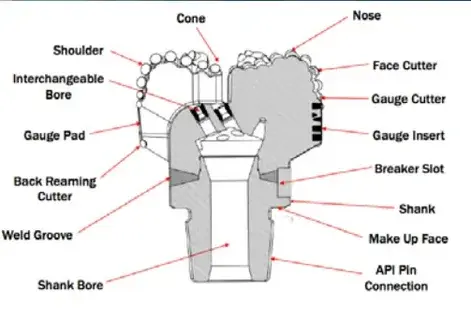

Optimizing Bit Profile

The overall profile of the drill bit significantly influences its performance in varying hard rock formations:

- Cone Angle: Adjusting the cone angle affects the bit's stability and penetration rate. Steeper cone angles are often used for harder formations to concentrate weight on fewer cutters.

- Shoulder Angle: Optimizing the shoulder angle helps balance directional stability with rate of penetration, particularly important in heterogeneous formations.

- Gauge Length: The length of the gauge section is tailored to provide the right balance between stability and steerability in different rock types.

Enhancing Hydraulics

Effective hydraulics are crucial for bit performance, especially in hard rock formations:

- Nozzle Placement: Strategic placement of nozzles ensures efficient cuttings removal and cooling of the cutters, critical in abrasive hard rock environments.

- Junk Slot Area: Optimizing the junk slot area improves cuttings evacuation, preventing bit balling in formations that produce fine cuttings.

- Flow Distribution: Balancing flow across the bit face helps maintain even cutter cooling and cleaning, essential for consistent performance in varying rock types.

Material Selection

Choosing the right materials for different components of the drill bit is crucial for performance in hard rock formations:

- Cutter Grade: Selecting the appropriate PDC cutter grade balances wear resistance and impact strength for specific rock types.

- Matrix Material: The composition of the matrix material is optimized to provide the necessary erosion resistance and thermal stability for different formation types.

- Hardfacing: Application of specialized hardfacing materials protects critical areas of the bit from excessive wear in abrasive formations.

Incorporating Advanced Technologies

Leveraging cutting-edge technologies can significantly enhance drill bit performance across varying hard rock formations:

- Finite Element Analysis (FEA): Utilizing FEA helps predict bit behavior under different loading conditions, allowing for optimized design before physical testing.

- Computational Fluid Dynamics (CFD): CFD simulations aid in optimizing hydraulics for specific formation types, improving cleaning efficiency and heat dissipation.

- Rock Mechanics Modeling: Advanced modeling of rock-cutter interactions helps tailor bit designs to specific formation properties, enhancing overall drilling efficiency.

Four Wing Arc Angle PDC Drill Bits that are highly optimized for different types of hard rock formations can be made by makers who carefully consider these factors and keep improving designs based on data from field performance. This method optimizes drilling and increases bit life, which lowers overall drilling costs and makes the job more profitable.

Conclusion

To get the most out of your burrowing, you ought to know how circular segment points alter for distinctive sorts of difficult shake. Geographical components, shake qualities, and the plan of penetrate bits are all associated in complicated ways that appear how difficult it is to do boring nowadays. If boring engineers and bit producers carefully think almost these things and utilize cutting edge advances, they can make instruments like the Four Wing Arc Angle PDC Drill Bit work much way better in a wide run of difficult shake arrangements.

In difficult drilling operations, choosing the appropriate drill bit configuration is crucial for oil and gas drilling firms, oil service businesses, and other organizations. Specialized in offering state-of-the-art drilling solutions customized to meet your unique requirements is Shaanxi Hainaisen Petroleum Technology Co., Ltd. For your drilling operations, our team of professionals is prepared to help you select the best drill bit design for your particular geological circumstances, guaranteeing maximum effectiveness and economy.

Don't let challenging formations hinder your drilling progress. Contact us today at hainaisen@hnsdrillbit.com to discover how our advanced Four Wing Arc Angle PDC Drill Bits and customized solutions can revolutionize your drilling operations. Let's work together to overcome your toughest drilling challenges and achieve unprecedented levels of performance and reliability.

References

1. Smith, J.R. and Brown, T.L. (2019). "Optimization of PDC Bit Design for Variable Hard Rock Formations." Journal of Petroleum Technology, 71(5), pp. 62-70.

2. Garcia, M.E. et al. (2020). "Arc Angle Variations in Hard Rock Drilling: A Comparative Study." Rock Mechanics and Rock Engineering, 53(8), pp. 3745-3760.

3. Johnson, K.L. and Williams, R.C. (2018). "Advanced Cutter Geometries for Improved Hard Rock Drilling Performance." SPE Drilling & Completion, 33(3), pp. 217-229.

4. Lee, S.H. and Park, J.Y. (2021). "Numerical Simulation of PDC Bit Performance in Various Hard Rock Formations." International Journal of Rock Mechanics and Mining Sciences, 138, 104630.

5. Thompson, A.R. and Davis, E.M. (2017). "The Impact of Arc Angle Design on PDC Bit Durability in Abrasive Formations." Geothermics, 69, pp. 102-114.

6. Wilson, C.G. and Martinez, A.L. (2022). "Optimizing Drill Bit Hydraulics for Enhanced Performance in Hard Rock Environments." Journal of Natural Gas Science and Engineering, 98, 104359.