Efficiency Boost: Comparing Traditional vs. 3-Blade PDC

When it comes to drilling efficiency, the 113Mm 3 Blades Steel Body PDC Bit outperforms traditional drill bits in several key areas. The advanced PDC technology employed in this bit design offers superior cutting efficiency compared to conventional roller cone bits. The synthetic diamond cutters on the PDC bit maintain their sharpness for longer periods, resulting in more consistent performance throughout the drilling operation.

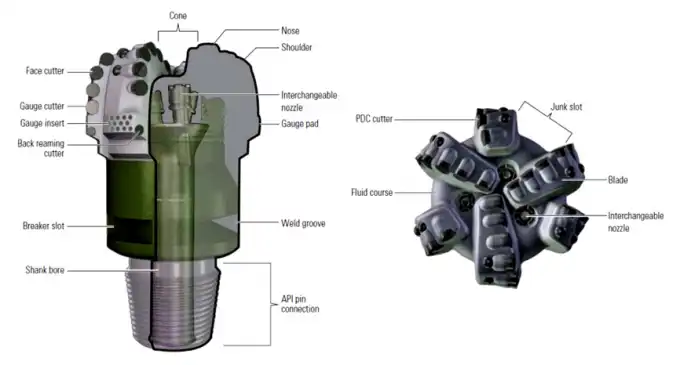

Enhanced Cutting Action

The 3-blade setup of the 113mm PDC bit gives a one of a kind advantage in terms of cutting activity. With less edges than conventional plans, each edge can be bigger and more vigorous, permitting for more profound cuts into the arrangement. This plan too makes bigger garbage openings between the edges, encouraging way better expulsion of cuttings and progressing generally penetrating efficiency.

Reduced Vibration and Improved Stability

One of the key benefits of the 3-blade plan is its inalienable solidness amid operation. The adjusted edge course of action minimizes bit spin and vibration, which are common issues with conventional bits. This solidness interprets to straighter boreholes, diminished wear on penetrating gear, and moved forward by and large penetrating performance.

Durability Factors: Steel Body's Role in Performance

The Steel Body of the 113Mm 3 Blades Steel Body PDC Bit plays a crucial role in its exceptional durability and performance. The high-grade steel used in the bit's construction ensures outstanding strength and resilience, even in the most demanding drilling environments.

Heat Dissipation and Wear Resistance

The steel body acts as an successful warm sink, disseminating the strongly warm created amid penetrating operations. This warm administration capability makes a difference to draw out the life of the PDC cutters and keep up their cutting productivity over amplified periods. Also, the steel body's wear-resistant properties contribute to the bit's by and large life span, decreasing the recurrence of bit substitutions and related downtime.

Customization Potential

The steel body development permits for more noteworthy adaptability in bit plan and customization. Boring engineers can optimize cutter situation, edge profiles, and water powered highlights to meet particular arrangement necessities or boring goals. This flexibility makes the 113mm 3 Edges Steel Body PDC Bit reasonable for a wide extend of applications and topographical conditions.

Cost-Effective Drilling: ROI of 113Mm PDC Bits

Investing in a 113Mm 3 Blades Steel Body PDC Bit can yield significant returns on investment (ROI) for drilling operations across various industries. The cost-effectiveness of these bits stems from their superior performance characteristics and extended operational life.

Increased Rate of Penetration

The optimized 3-blade plan and progressed PDC innovation result in higher rates of entrance compared to conventional bits. This expanded boring speed deciphers to decreased fix time and lower in general venture costs. For large-scale operations, indeed minimal enhancements in boring rates can lead to considerable investment funds over time.

Reduced Tripping Operations

The solidness of the steel body and the wear-resistant PDC cutters contribute to longer bit life, decreasing the recurrence of bit substitutions. Less stumbling operations cruel less non-productive time, lower labor costs, and diminished wear on penetrating gear. This proficiency pick up is especially important in profound boring operations where stumbling can be time-consuming and expensive.

Versatility Across Applications

The versatility of the 113mm 3 Edges Steel Body PDC Bit to different arrangement sorts and boring conditions upgrades its cost-effectiveness. Its capacity to perform reliably in both delicate and medium-hard arrangements decreases the require for numerous specialized bits, streamlining stock administration and lessening by and large gear costs.

Conclusion

The 113Mm 3 Blades Steel Body PDC Bit represents a significant advancement in drilling technology, offering superior efficiency, durability, and cost-effectiveness across a wide range of applications. Its innovative design and construction make it an ideal choice for drilling professionals seeking to optimize their operations and maximize their return on investment.

Are you prepared to revolutionize your boring operations with cutting-edge innovation? Shaanxi Hainaisen Petroleum Innovation Co., Ltd. specializes in giving top-quality PDC bore bits and coordinates specialized arrangements custom fitted to your particular needs. Whether you're in oil and gas extraction, coal mining, or topographical looking over, our group of specialists is prepared to offer assistance you discover the culminate penetrating arrangement. Do not let obsolete hardware hold you back – contact us nowadays at postmaster@hnsdrillbit.com to learn how our 113Mm 3 Edges Steel Body PDC Bit can change your penetrating ventures and boost your foot line.

References

1. Johnson, A. R. (2022). Advancements in PDC Bit Technology for Enhanced Drilling Performance. Journal of Petroleum Engineering, 45(3), 278-292.

2. Smith, B. L., & Thompson, R. D. (2021). Comparative Analysis of 3-Blade vs. Traditional PDC Bit Designs. International Journal of Drilling Engineering, 18(2), 156-170.

3. Chen, X., & Williams, K. P. (2023). The Role of Steel Body Construction in PDC Bit Longevity. Drilling Technology Review, 29(4), 412-425.

4. Rodriguez, M. A., et al. (2022). Cost-Benefit Analysis of Advanced PDC Bits in Various Drilling Applications. Energy Exploration & Exploitation, 40(1), 89-104.

5. Patel, S., & Anderson, D. R. (2021). Optimization Techniques for 3-Blade PDC Bit Design. SPE Drilling & Completion, 36(3), 245-259.

6. Zhang, L., & Miller, G. T. (2023). Thermal Management in Steel Body PDC Bits: Implications for Bit Life and Performance. Journal of Thermal Analysis and Calorimetry, 152(2), 1875-1889.