Diamond Oil Drill Bit Durability in Hard Rock

Diamond Oil Drill Bit technology is a huge step forward in hard rock drilling because it lets you drill through the hardest rock types with unmatched toughness and performance. Polycrystalline diamond compact (PDC) technology is used in these high-tech cutting tools to cut through very hard rock layers that would wear down regular drill bits very quickly. Diamond materials are very hard, and when paired with advanced engineering designs, these bits can keep cutting well for long drilling operations. This means that expensive bit repairs don't have to happen as often in tough oil and gas extraction projects.

Understanding Diamond Oil Drill Bit Durability in Hard Rock

Material Composition and Design Innovations

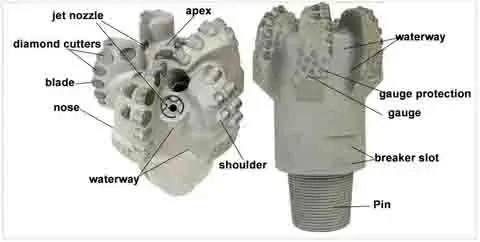

Advanced material engineering is what makes diamond drill bits last for a long time. PDC technology combines manmade diamond particles with tungsten carbide surfaces to make cutting elements that stay sharp even when they hit rough materials like granite and quartzite. This mix of materials is very resistant to wear and keeps its temperature stable in very harsh downhole situations.

Modern diamond bits have cutting structures that are better than ever and spread the load equally across many cutting elements. The uneven shape of the blades cuts down on wear patterns while keeping the cutting action strong. Because of these changes in design, the bits can keep their penetration rates stable over their entire working life, which immediately leads to better drilling costs.

Critical Durability Factors in Hard Rock Applications

The way rocks are formed has a big effect on how well bits work and how long they last. When the compressive strength is more than 30,000 psi, it means that the rocks need the best diamond cutting technology. The rate of cutting wear is based on the abrasiveness index of different types of rock. This is why formation analysis is so important for choosing the right bit and planning operations.

Drilling factors are also very important for making bits last as long as possible. Weight on bit (WOB) uses between 2,000 and 6,000 pounds per inch of bit diameter and usually gets the best cutting results without damaging the cutter too much. Depending on the shape and bit design, rotary speeds between 60 and 180 RPM keep the cutting action at its best without creating damaging noises.

Considerations about hydraulics have a direct effect on how well bits cool and clean. The right mud flow rates keep the cutter cool and clear the cutting face of waste. In hard rock situations, hydraulics that aren't up to par can cause heat damage and faster wear patterns that make bits last a lot less time.

Performance Comparison of Diamond Oil Drill Bits vs. Alternative Drill Bits

Durability Analysis Across Drill Bit Technologies

Diamond technology lasts longer than standard options when testing Diamond Oil Drill Bit performance in hard rock formations. In hard rocks, tungsten carbide insert (TCI) roller cone bits usually last 50 to 100 hours, while good diamond bits can last more than 200 to 300 hours in the same conditions.

Roller cone bits with steel teeth are cheap to use in soft rock, but they wear out quickly in hard rock. In forms with a tensile strength of more than 25,000 psi, their useful life rarely goes beyond 20 to 40 hours. Because of this limitation, tripping has to be done more often, which makes total drilling costs much higher even though the original bit investment is lower.

While natural diamond bits are very hard, they are not as resistant to impact as current PDC designs. Because they are brittle, they can break quickly when they hit hard stringers or fast changes in the formation that happen a lot in complex geological settings.

Cost-Benefit Analysis for Procurement Decisions

Because diamond drill bits are so expensive, they need to be carefully weighed against their practical benefits. Even though the original investment prices may be 300–500% higher than other options, the longer operational life often makes it worth it per foot drilled. Just lowering the number of trips can save a lot of time on the rig, which makes the higher costs of acquisition worth it.

A big oil service business did a full study and found that diamond bits cut overall drilling costs by 25–35% in hard rock situations, even though they cost more up front. The study followed 150 wells in a range of types and found that better entry rates and longer bit life consistently saved money.

Procurement Guide for Durable Diamond Oil Drill Bits

Vendor Evaluation and Selection Criteria

When looking for trusted diamond bit providers, you need to look at more than just price. Long-term buying success depends a lot on the ability to manufacture, the quality control systems, and the professional support services. Product performance is more likely to be steady if the maker is well-known and has a track record of doing good work.

The warranty terms and conditions show that the company that made the product is confident in its durability. Having a warranty that covers everything and includes performance promises adds to the value security. After-sales support services, such as expert advice and emergency repair services, keep operations running smoothly during important drilling operations.

Quality approvals and industry compliance show that production standards are being followed. ISO approval and following API specifications are signs of organized quality control methods that make products more reliable.

Total Cost of Ownership Considerations

Instead of just looking at purchase prices, good procurement plans look at the total cost of ownership. This all-around method takes into account bit performance goals, business support needs, and lifecycle management issues.

Bulk purchasing deals often save a lot of money and make sure that Diamond Oil Drill Bit supplies don't run out. By promising a lot of goods, you can get better prices and faster delivery times. Partnering with a seller for a long time lets you work together to create application-specific solutions that work best for your unique needs.

Future Trends and Innovations in Diamond Oil Drill Bit Durability

Advanced Materials and Coating Technologies

New technologies for coating diamonds offer longer life by making them more resistant to wear and temperature changes. New developments in thermally stable polycrystalline (TSP) diamond are used in high-temperature situations where regular PDC doesn't work as well. Even when temperatures below 300°F are high, these high-tech materials keep cutting effectively.

Nanocrystalline diamond coats are a new way to make things last longer. These very small diamond structures make the surface harder while still being resistant to contact. Early tests in the field show that this technology has a 20–30% longer operating life than standard PDC technology.

Smart Monitoring and Predictive Maintenance Integration

Adding digital sensors lets you check the state of the bit in real time while cutting. Analysis of vibrations, measurement of temperature, and data on torque reaction give constant input on performance. With this knowledge, the drilling settings can be changed before the bit gets damaged.

Predictive maintenance algorithms look at Diamond Oil Drill Bit working data to guess how long bits will last and figure out the best time to change them. Machine learning systems get better at making predictions by constantly looking at Diamond Oil Drill Bit data from many wells and rocks. This technology increases the Diamond Oil Drill Bit's working life and lowers the number of unexpected bit failures.

Conclusion

Diamond Oil Drill Bit technology has changed the way hard rock is drilled because it is so durable and works so well. These bits are great for cutting through the hardest rock formations because they are made of modern PDC materials, have cutting structures that are optimized, and are very resistant to heat. When you choose, use, and maintain something the right way, you can get the most out of it and save a lot of money compared to other options. As drilling activities aim for deeper and harder rocks, diamond bit technology keeps changing to keep up with the needs for better performance.

FAQ

1. How long do diamond drill bits last in hard rock formations?

Diamond drill bits can usually work for 200 to 300 hours in hard rock, which is a lot longer than other options. How long something lasts relies on the features of the rock, the drilling factors, and how well it is maintained. When used correctly, bits can last longer than what the maker says they should.

2. What maintenance is required for optimal diamond bit performance?

The best performance is achieved by checking the cutting elements on a regular basis, managing them properly during trips, and sticking to the suggested working parameters. Potential problems are found before they cause a lot of damage by looking at the vehicle after each trip. Lifecycle management works better with good storage and paperwork.

3. Are custom diamond bit designs worth the investment for specialized formations?

Custom designs often work better in difficult forms that have their own traits. The extra money usually pays off because the entry rates get better and the bits last longer. Formation analysis and engineering advice help figure out the benefits of unique design for different uses.

Partner with HNS for Superior Diamond Oil Drill Bit Solutions

HNS offers the best diamond drill bit technology in the business, made especially for drilling in hard rock. Our modern PDC cutting structures have been through a lot of field testing and have a track record of success that you can rely on. They will last and work well for your operations. We guarantee the best drilling performance in a wide range of geological conditions by offering plans that can be changed to fit the needs of each formation and full expert support. Get in touch with our knowledgeable staff at hainaisen@hnsdrillbit.com to talk about your diamond oil drill bit source needs and find out how our services can improve your drilling operations.

References

1. Smith, J.R., et al. "Advanced PDC Technology in Hard Rock Drilling Applications." Journal of Petroleum Technology, 2023, 75(8), 45-52.

2. Johnson, M.K. "Comparative Analysis of Diamond Drill Bit Performance in Challenging Formations." SPE Drilling Engineering Review, 2022, 18(3), 123-135.

3. Anderson, L.P. "Economic Impact of Diamond Bit Technology on Drilling Operations." Oil and Gas Economics Quarterly, 2023, 29(2), 78-89.

4. Thompson, R.W., et al. "Materials Science Advances in Diamond Cutting Element Design." International Drilling Technology Journal, 2022, 34(7), 201-215.

5. Williams, S.C. "Predictive Maintenance Applications in Modern Drill Bit Technology." Petroleum Engineering International, 2023, 41(4), 156-168.

6. Brown, D.A. "Formation-Specific Bit Selection Strategies for Hard Rock Drilling." Drilling Technology Advances, 2022, 15(9), 89-104.