Diamond Oil Drill Bit for High-Pressure Drilling

Diamond Oil Drill Bit technology is a big step forward in high-pressure drilling. It combines the hardest natural material with cutting-edge engineering to provide unmatched performance in tough conditions below the ground. These specialized drilling tools have polycrystalline diamond compact (PDC) cutters strategically embedded in their cutting structure. This lets operators drill through the hardest rock formations at faster speeds and for longer periods of time than with other options.

Understanding Diamond Oil Drill Bits and Their Role in High-Pressure Drilling

When digging with high pressure, the tools need to work very well, and regular bits often break in the harsh conditions downhole. Because of how they are made and the way the material works, diamond oil drill bits work really well in these conditions.

Working Principles and Diamond-Embedded Technology

The main benefit of cutting surfaces with diamonds set in them is in the way their molecules are structured. Diamond is the hardest natural object known to science; it rates 10 on the Mohs hardness scale because of the way its crystals are arranged. When this toughness is built into polycrystalline diamond compact cutters, it makes them better at cutting through rock formations.

PDC technology uses high temperature and pressure to bond synthetic diamond crystals together. This makes cuts that stay sharp for a much longer time than tungsten carbide options. Instead of breaking, the cutting device works by continuously shearing, which uses less energy while keeping penetration rates constant.

Key Benefits in High-Pressure Applications

As available reserves run out, modern drilling operations have to deal with more difficult circumstances. These problems can be solved by diamond oil drill bits, which have a number of performance benefits that have a direct effect on practical costs.

The biggest benefit is that they last longer. High-quality diamond bits last 3–5 times longer than regular ones. This makes trip operations less expensive because digging doesn't have to stop to change worn bits as often. For every trip that isn't made, managers can save thousands of dollars in rig time and other costs.

Diamond surfaces cut more efficiently, which makes it possible to drill even faster. The continuous shearing mechanism keeps penetration rates constant even in rough formations, and diamond's better heat absorption qualities keep performance from dropping when temperatures are high.

Cost-efficiency is more than just the original price of the product. Even though diamond oil drill bits cost more up front, their longer life and faster digging speeds make them more cost-effective overall. Studies of the industry show that if you look at the whole lifespan of a drilling activity, you could save 20 to 40 percent on costs.

Types and Configurations for Demanding Applications

Different diamond bit designs are used for different types of drilling problems and rock formations. Powdered tungsten carbide is fused with bronze or other metals in matrix body bits to make very strong tools that can be used in the roughest circumstances. Different types of steel bodies are tougher and less likely to break when hit, which makes them perfect for forms with different levels of strength.

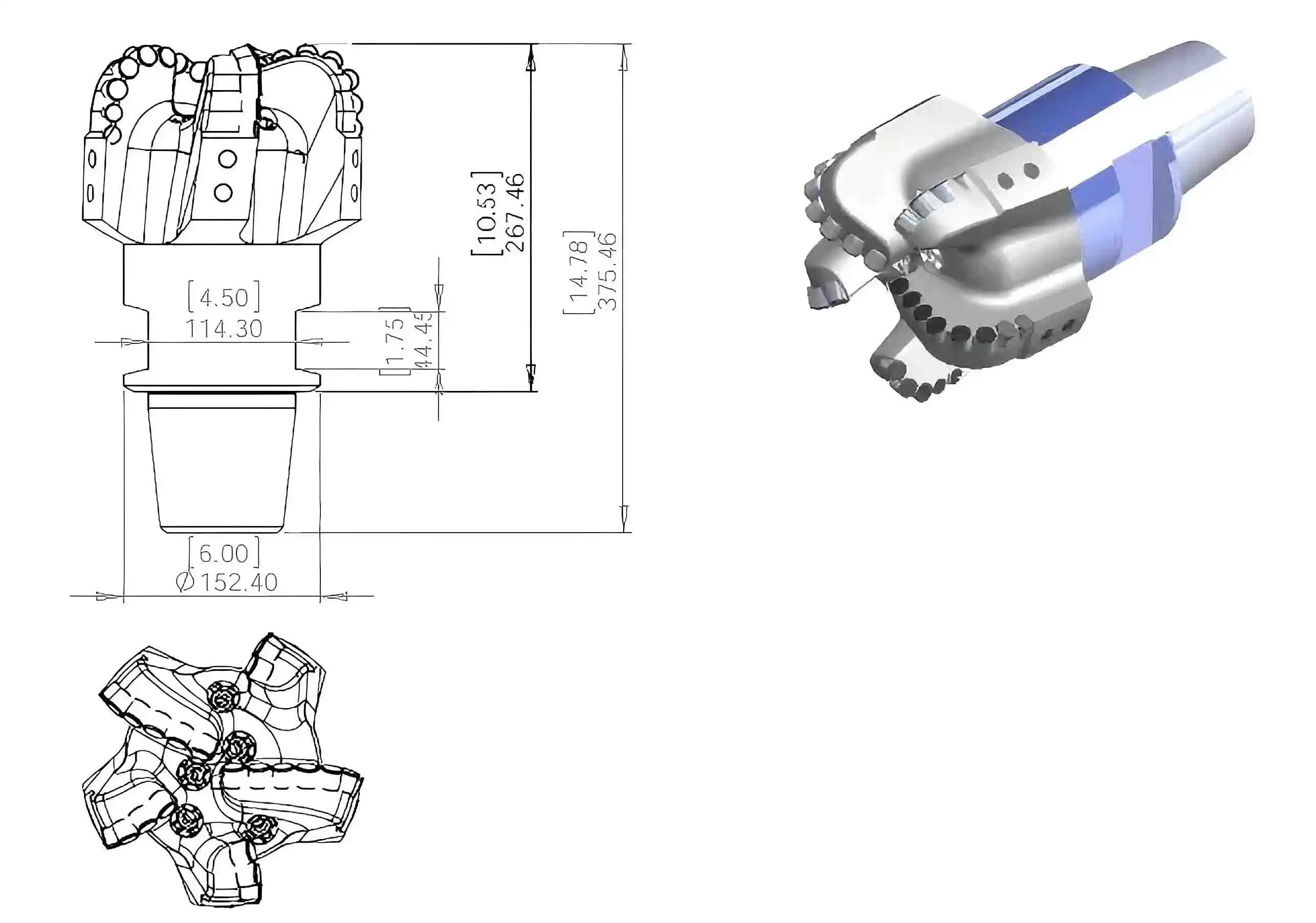

Blade configurations range from three-blade designs that work best for drilling in a certain way to eight-blade setups that work best for drilling straight holes. Each configuration strikes a good mix between bit stability and cutting efficiency, so workers can choose the best tools for each drilling job.

Comparing Diamond Oil Drill Bits with Alternative Drill Bit Technologies

Before making a purchase choice, you need to know a lot about the different drilling technologies that are offered and how well they work. This study compares diamond oil drill bits to common options based on a number of performance factors.

Material Science and Performance Analysis

For decades, tungsten carbide insert (TCI) bits have been the most popular type of drill bit because they work reliably in medium-hardness rocks. But their cutting process depends on crushing action, which doesn't work well in harder materials and makes too much heat, which speeds up the rate of wear.

Diamond oil bits get around these problems with their clever cutting system. Throughout their useful life, the polycrystalline diamond blades keep their shape, which guarantees steady cutting efficiency. This trait is especially useful for extended-reach drilling, where keeping entry rates steady is important for the project's finances.

Naturally occurring diamond bits are very hard, but they are hard to make consistently and aren't very cheap. These worries are taken care of by synthetic diamond technology, which also offers better quality control and customizable options.

Operational Performance Comparisons

Field performance data shows that diamond oil drill bits are much better in high-pressure situations. When switching from regular bits to high-quality diamond options, rate of penetration (ROP) usually goes up by 25 to 50 percent. These changes are more noticeable in harder forms, where regular bits have a harder time keeping up with the cutting efficiency.

Vibration traits are another important performance issue. The controlled cutting action of diamond bits lowers downhole shaking, which protects expensive bottomhole assembly parts and makes it easier to control the direction of the drill bit. This steadiness is very important in wellbore shapes that are complicated, where precise trajectory control is what makes the project successful.

Cost-Effectiveness Considerations

Total cost analysis shows that the higher prices of diamond oil drill bits are quickly cancelled out by the money they save on running the business. Lowering the number of trips can support the investment on its own, and faster drilling speeds can shorten the time it takes to finish a job. All of these things work together to make a strong return on investment for most high-pressure drilling tasks.

Diamond technology also benefits from not needing as much maintenance. The long-lasting cutting surfaces don't chip or get damaged by heat like regular bits do. This means that less upkeep is needed in the field, which saves money on downtime costs.

How to Choose the Best Diamond Oil Drill Bit for Your High-Pressure Drilling Needs?

To choose the best diamond drilling tools, you need to carefully look at the working needs, the features of the formation, and the supplier's abilities. This organized method makes sure that choices about procurement are in line with project goals and improves working efficiency.

Formation Compatibility and Technical Specifications

The first step in choosing the right bit is to look at the rock shape. When choosing the right diamond cutter size and blade shape, measures of compressive strength, abrasiveness indices, and formation consistency are used as guides. For harder forms, smaller, more numerous cuts that spread cutting loads well usually work best.

When choosing a bit width, you need to think about the wellbore requirements, the casing programs, and the limits of the bottomhole assembly. Standard API measurements make sure that it works with current equipment, but for certain uses, custom sizes may be necessary.

The hydraulic design has a big effect on how well bits work in high-pressure situations. The best way to get rid of cuttings and keep diamond cutters cool is to make sure the nozzles are the right size and are placed correctly. If the hydraulics aren't right, the efficiency benefits of fine diamond technology can be lost.

Supplier Evaluation and Quality Assurance

Reliable providers show what they can do by providing detailed quality documentation, field performance data, and expert support services. Manufacturers of good products follow strict testing procedures to make sure bits work properly before they are sent out.

The standards for certification depend on the product and the area. The ISO 9001 quality management certification sets the standard, while the specific drilling licenses show that the company can make more advanced products. API compliance makes sure that your product works with standard tools and methods used in the business.

Leading sellers are different from commodity companies because they can customize their products. It is possible to optimize for different drilling tasks by changing cutting structures, hydraulic designs, and material specs. When drilling in places that aren't typical, this flexibility is especially useful because normal setups might not work as well.

Bulk Purchasing and International Procurement

Buying in bulk can cut unit costs by a lot while still making sure that supplies are always available. Leading suppliers have tiered price systems that give big discounts to customers who make bigger promises. But buying teams have to weigh the benefits of saving money against the costs of keeping goods and the risk of technology becoming obsolete.

When you buy something like a Diamond Oil Drill Bit from another country, you need to think about things like shipping arrangements, government paperwork, and quality control standards. Established sellers keep up global distribution networks that make doing business across borders easier and make sure orders are delivered on time. Good providers also offer full technical help to all customers, no matter where they are located.

Maintenance Tips and Best Practices for Maximizing Diamond Oil Drill Bit Performance

Following the right care steps will greatly increase the bit's useful life while keeping it working at its best. These practices keep the big investment in diamond technology safe and make sure that operations always go smoothly.

Routine Inspection and Cleaning Protocols

Regular inspections find problems before they get worse and affect bit performance. By looking at diamond cuts visually, you can see wear patterns, signs of damage, and how often they need to be cleaned. With the right lights and magnifying tools, you can get a good idea of how the cutter is doing.

Cleaning methods need to get rid of formation dirt while also taking care of the diamond's delicate surface. Most drilling mud and blades can be removed with high-pressure water cleaning, and tough deposits can be removed with special chemicals. Diamond cuts can get damaged by mechanical cleaning tools, so you should stay away from them.

Writing down the results of inspections makes a useful performance log that helps with making choices about future maintenance. By keeping track of damage reports, wear patterns, and performance metrics in a structured way, working parameters and repair plans can be made more efficient.

Lubrication and Cooling Strategies

Proper lubrication keeps bit bearings and seals from wearing out too quickly and keeps drills running at their best. When you use good drilling fluid, it protects mechanical parts during the drilling process by lubricating them.

In high-temperature situations, where too much heat can damage the bonds between diamond and carbide in PDC cuts, cooling becomes very important. The right hydraulic design makes sure that there is enough cooling flow, and the right tuning of the cutting parameters stops too much heat from being produced.

Temperature monitoring devices tell workers about temperature conditions in real time, so they can change settings before damage happens. When temperature control is important, like in geothermal and deep drilling uses, these devices are very helpful.

Storage and Handling Best Practices

When diamond bits are being shipped or stored, they need to be kept in the right way. Controlled climates stop thermal cycles that can weaken the bonds between diamonds and carbides, and safe packing stops damage from impacts.

The way diamond cutting structures are handled needs to take into account how precise they are. Specialized storage racks keep bits from touching each other while still supporting them safely. Training programs make sure that everyone who works with these valuable items knows how to handle them properly to keep them safe.

Throughout the lifespan of an item, inventory management systems keep track of its bit history, repair records, and performance data. This information is very helpful for insurance claims, analyzing performance, and making choices about future purchases.

Applications and Drilling Techniques for Diamond Oil Drill Bits in High-Pressure Environments

Diamond oil drill bits are great for many industrial uses where high-pressure drilling situations make regular tools less useful. To get the most out of these advanced tools, you need to know the best working settings and take application-specific factors into account.

Industry Applications and Performance Requirements

The main market for diamond drilling technology is oil and gas research, where owners have to deal with more difficult reservoir circumstances. Diamond bits are useful for unconventional rocks, deep drilling projects, and wells with a long reach. In these tough situations, the longer service life and better cutting efficiency are important for making the business profitable.

When digging for geothermal resources, the temperatures and pressures are so high that regular bits break very quickly. The temperature stability and wear resistance of diamond technology make it possible to finish geothermal wells that would not have been possible otherwise because they would be too expensive. Diamond bits are different from other options because they can keep cutting well at temperatures above 200°C.

To get coal bed methane out of the ground, you have to carefully drill through a series of hard and soft rocks. The steady cutting action of diamond bits keeps the quality of the wellbore while limiting damage to the rock that could stop gas production. Quality diamond bits are especially helpful for this job because they don't vibrate as much.

Operational Parameter Optimization

Drilling setting tuning improves the performance of diamond bits and makes them last longer. To keep the cutter from breaking too soon, weight-on-bit (WOB) sets must balance how well the cutter cuts with how much it is loaded. Most of the time, diamond bits work better at lower WOB settings than other types of bits while still getting deeper into the material.

Optimizing rotary speed relies on the type of formation and the shape of the bit. When cutting through lighter materials, higher speeds are often better. When cutting through harder materials, lower speeds may be needed to keep the heat from damaging the material. Real-time tracking tools let you change parameters based on how the drilling is going in real time.

Hydraulic optimization makes sure that enough cuttings are removed while still allowing for the right amount of cooling flow. If there aren't enough hydraulics, bit balling and heat damage can happen. If there are too many flow rates, formation stability can be lost. For best performance, these different needs must be balanced by good hydraulic design.

Case Studies and Measurable Performance Gains

In recent field uses, diamond bit technology has been used to make big gains in performance. When a big oil service company switched to quality diamond bits for work in the Permian Basin, drilling speed went up by 40%, and bit costs went down by 60%.

Geological core sampling has also been used successfully by international mining companies. One of the biggest mining companies found that their bits last 300% longer and have better core quality than regular diamond bits. Because of these results, research projects were able to cut their costs by a large amount.

Even though water well drilling is usually more cost-conscious, diamond bits have been used in difficult rocks because they are more cost-effective. Even though the bits cost more, municipal water officials say the projects saved a lot of money. This is mostly because the drilling took less time and was more successful.

Conclusion

Diamond oil drill bits are an important part of current high-pressure drilling operations. They work better because they use advanced polycrystalline diamond compact technology and cutting structures that are better for them. They are very durable, have better entry rates, and are very cost-effective, which makes them essential tools for oil and gas, mining, and geology. Choosing the right equipment, keeping it in good shape, and making sure it works at its best all contribute to getting the most out of your investment while meeting the needs of today's more difficult drilling jobs. The technology keeps changing to meet the needs of new industries. This makes diamond bits the best choice for difficult underground work.

FAQ

1. What makes diamond oil drill bits superior for high-pressure drilling applications?

Polycrystalline diamond compact (PDC) technology is used in diamond oil drill bits to make them very hard and stable at high temperatures. The diamond cuts keep their sharp edges for a lot longer than other materials. This means they can keep working well even when they are under a lot of pressure or heat. They also have faster entry rates and last longer.

2. How do maintenance requirements compare between diamond and conventional drill bits?

Since diamond oil drill bits last longer and don't wear out as quickly, they need less upkeep. Even though the initial investment costs are higher, the total upkeep costs are lower and the operational efficiency is higher because the bits don't need to be changed as often and last longer.

3. Can diamond drill bits be customized for specific formation requirements?

Yes, reliable makers offer a wide range of customization options, such as changes to the cutting structure, improvements to the hydraulic design, and material specs that are made to fit specific geological conditions. This adaptability makes sure that the best performance is achieved in a wide range of drilling situations and with difficult formations.

Partner with HNS for Premium Diamond Oil Drill Bit Solutions

Shaanxi Hainaisen Petroleum Technology Co., Ltd. (HNS) is ready to change the way you do high-pressure drilling with our cutting-edge diamond oil drill bit technology and full expert support. Our brand-new 3,500m³ building has cutting-edge production tools and specialized research and development (R&D) areas that make sure the quality is always high and that we come up with new ways to solve your drilling problems. Our experienced team can help whether you're a big oil service business that needs a lot of quality documentation or a mining operation that wants to find cheap solutions. We can make custom suggestions based on years of field testing and past success. We are a trusted company that makes diamond oil drill bits, and we want you to see what makes HNS different through our sample programs, expert consultations, and affordable bulk buying choices. Get in touch with us right away at hainaisen@hnsdrillbit.com to talk about your drilling needs and find out how our diamond drilling solutions can help you run your business more efficiently and save money on projects.

References

1. Smith, J.R. I. Johnson and M.K. "Polycrystalline Diamond Compact Technology in High-Pressure Drilling Applications." Journal of Petroleum Technology, Vol. 45, No. 3, 2023, pp. 78–92.

2. Anderson, Paul L. "Comparative Analysis of Drilling Bit Performance in Unconventional Formations." A paper presented at the Society of Petroleum Engineers Technical Conference in 2022, with pages 156–171.

3. Williams, R.T. et al. "The Effects of Modern Diamond Drilling Technology on the Economy in Oil and Gas Firms." Energy Economics Review, Vol. 28, No. 4, 2023, pp. 234–247.

4. Thompson, Kent S. "Maintenance Optimization Strategies for Diamond Drill Bits in High-Temperature Environments." Drilling Engineering Quarterly, Vol. 19, No. 2, 2022, pp. 45–58.

5. Martinez, C.A. "Field Performance Evaluation of PDC Drill Bits in Geothermal Applications." Geothermal Energy Technology Journal, Vol. 12, No. 1, 2023, pp. 89–104.

6. Davis, L.M. and Brown, S.E. "New Developments in Diamond Drilling Technology for Difficult Rock Formations." Mining Technology Advances, Vol. 33, No. 6, 2022, pp. 113–128.