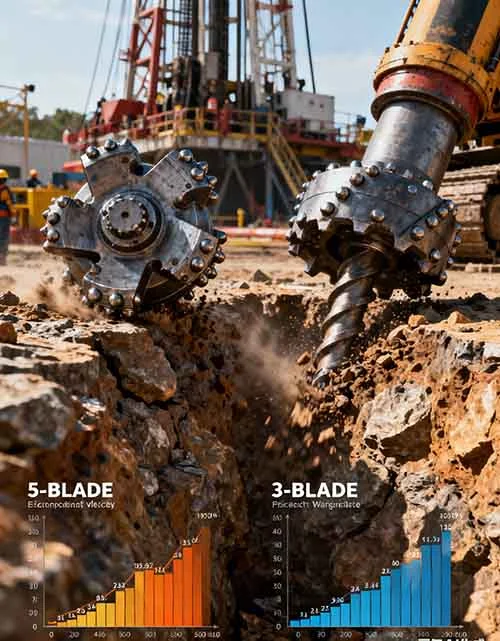

5-blade vs 3-blade: cutter layout, hydraulic balance and impact resistance

Cutter Layout and Distribution

The cutter layout is a fundamental aspect that distinguishes 5-blade from 3-blade PDC bits. 5 Blades Steel Body High Performance PDC Rock Drill Bits designs offer a more intricate and densely packed cutter arrangement, allowing for a larger number of cutting elements to be placed on the bit face. This increased cutter density results in several advantages:

- Enhanced rock-cutting efficiency due to more points of contact with the formation

- More uniform weight distribution across the bit face, reducing the load on individual cutters

- Improved ability to maintain gauge and resist wear in abrasive formations

In contrast, 3-blade designs feature a simpler cutter layout with fewer cutting elements. While this can be advantageous in certain soft formations where aggressive cutting is desired, it may lead to faster wear and reduced stability in harder rock types.

Hydraulic Balance and Cleaning Efficiency

Hydraulic balance is crucial for efficient cuttings removal and bit cooling during drilling operations. The 5-blade configuration typically offers superior hydraulic performance due to:

- More evenly distributed junk slots between blades, promoting better fluid flow

- Reduced risk of bit balling in sticky formations

- Enhanced cooling of PDC cutters, prolonging their operational life

The additional blades in a 5-blade design create a more balanced hydraulic profile, ensuring that drilling fluid is distributed more uniformly across the bit face. This improved fluid dynamics contributes to better hole cleaning and reduced risk of bit damage due to inadequate cooling.

3-blade bits, while offering larger junk slots, may experience less uniform fluid distribution and potentially higher risk of cuttings accumulation in certain formations.

Impact Resistance and Bit Stability

When it comes to withstanding the harsh conditions encountered during drilling operations, 5-blade PDC bits often demonstrate superior impact resistance and stability:

- The additional blades provide increased structural support, reducing vibration and improving overall bit stability

- More evenly distributed cutting forces across the bit face, minimizing the risk of blade failure

- Enhanced ability to maintain a straight borehole trajectory, particularly in directional drilling applications

The increased stability of 5-blade designs is particularly beneficial in formations with interbedded hard and soft layers, where sudden changes in rock hardness can cause significant bit damage or deviation.

3-blade bits, while potentially more aggressive in soft formations, may be more susceptible to vibration and instability in challenging drilling conditions.

Which rock types benefit most from 5-blade steel body PDC designs?

Optimal Performance in Medium to Hard Formations

5 Blades Steel Body High Performance PDC Rock Drill Bits excel in a wide range of rock types, but they particularly shine in medium to hard formations. The combination of increased cutter density and improved stability makes them ideal for:

- Limestone and dolomite formations commonly encountered in oil and gas drilling

- Abrasive sandstone and siltstone layers

- Interbedded shale and mudstone sequences

- Moderately hard igneous and metamorphic rocks in mining applications

The ability of 5-blade designs to maintain a consistent rate of penetration (ROP) in these challenging formations often results in significant time and cost savings over the course of a drilling project.

Advantages in Heterogeneous Formations

One of the best things about 5-blade PDC bits is that they work well in many types of rock formations. These bits can move smoothly across layers of different hardness without wearing out or vibrating too much because of their balanced cutter architecture and better stability. This trait is especially useful in:

- Sedimentary basins having layers that are hard and soft in turn

- Fractured or faulted areas where the rock qualities are hard to predict

- Formations that have chert or other hard materials inside them

5-blade bits can greatly cut down on the number of bit trips and the time it takes to fix them by keeping their performance steady during these tough times.

Performance in High-Angle and Horizontal Wells

The oil and gas industry's increasing focus on directional and horizontal drilling has further highlighted the benefits of 5-blade PDC bit designs. These bits offer several advantages in high-angle and horizontal well sections:

- Improved directional control and reduced tendency for bit walk

- Enhanced ability to maintain consistent weight on bit (WOB) in long horizontal sections

- Better resistance to lateral vibrations that can cause wellbore instability

These characteristics make 5-blade bits particularly well-suited for extended reach drilling (ERD) and complex multilateral well designs, where maintaining precise trajectory control is critical.

Trade-offs: ROP, torque control and replacement cost comparison

Rate of Penetration (ROP) Considerations

When evaluating the performance of 5-blade versus 3-blade PDC bits, rate of penetration is a critical factor. The trade-offs in this area include:

- 5-blade bits generally offer more consistent ROP across varied formations, but may have slightly lower peak ROP in soft rocks compared to 3-blade designs

- 3-blade bits can achieve higher instantaneous ROP in homogeneous soft formations due to their more aggressive cutting structure

- In harder formations, 5-blade bits often maintain higher average ROP over the course of a run due to reduced wear and improved stability

The choice between 5-blade and 3-blade designs should consider the specific formation characteristics and overall drilling program objectives. In many cases, the consistent performance of 5-blade bits can lead to higher overall ROP when considering the entire well section.

Torque Control and Drilling Efficiency

Torque management is crucial for optimizing drilling performance and preventing damage to downhole equipment. The comparison between 5-blade and 3-blade PDC bits in terms of torque control reveals:

- 5-blade bits typically generate more consistent and predictable torque responses, facilitating smoother drilling operations

- The increased cutter density of 5-blade designs allows for better distribution of cutting forces, reducing the risk of sudden torque spikes

- 3-blade bits may experience more variable torque, particularly when transitioning between formations of different hardness

For drilling operations utilizing sophisticated rotary steerable systems or motor assemblies, the more stable torque profile of 5-blade bits can contribute to improved tool face control and overall drilling efficiency.

Initial Cost and Replacement Considerations

When drilling operators choose bits, they always think about the economic side of things. When you compare 5-blade and 3-blade PDC bits, there are a few things to think about:

- 5-blade bits usually cost more at first since they are harder to make and have more PDC cutters.

- Life of the bit: 5-blade designs are frequently more durable, which means longer bit runs. This may make up for the greater initial cost.

- How often to replace: In tough formations, 3-blade bits may need to be replaced more often, which means additional non-productive time (NPT) for bit trips.

5 Blades Steel Body High Performance PDC Rock Drill Bits may cost more up front, but they can save a lot of money over the course of a drilling campaign because they can run longer and have less NPT. This is especially true for medium to hard formations or directional drilling.

Operational Flexibility and Risk Mitigation

Beyond the direct performance and cost considerations, the choice between 5-blade and 3-blade PDC bits also impacts operational flexibility and risk management:

- 5-blade bits offer greater versatility across a range of formation types, potentially reducing the need for multiple bit changes in heterogeneous intervals

- The improved stability of 5-blade designs can mitigate risks associated with vibration-induced damage to downhole tools and wellbore instability

- 3-blade bits may be preferred in specific scenarios where maximum aggressiveness is required, such as drilling out casing shoes or in very soft, homogeneous formations

Ultimately, the selection between 5-blade and 3-blade PDC bits should be based on a comprehensive analysis of the geological conditions, operational requirements, and economic factors specific to each drilling project.

Conclusion

The difference between 5-blade and 3-blade PDC bits shows how important it is to have custom solutions for different drilling problems as drilling technology is always changing. Three-blade bits are still useful in some situations, but 5 Blades Steel Body High Performance PDC Rock Drill Bits are the best choice for many operators because they work better in medium to hard formations, uneven intervals, and directional drilling situations.

The better structure of the cutter, better hydraulic balance, and higher stability of 5-blade designs lead to real benefits like consistent ROP, longer bit life, and less time spent not working. Most of the time, these benefits are worth the higher starting cost, especially in difficult drilling conditions where performance and dependability are very important.

Advanced PDC bit designs are becoming more and more important as drilling activities keep pushing the limits of depth, reach, and efficiency. By carefully looking at the needs of each drilling project and using the benefits of 5-blade technology, operators can improve the performance of their drilling, lower overall costs, and be more sure that they will reach their well building goals.

FAQ

1. What are the main advantages of 5-blade PDC bits over 3-blade designs?

5-blade PDC bits offer improved stability, more consistent ROP in varied formations, better hydraulic balance for efficient cleaning, and enhanced durability in medium to hard rock types. They excel in directional drilling and heterogeneous formations.

2. Are 5-blade PDC bits suitable for all drilling applications?

While 5-blade bits perform well in many scenarios, they are particularly advantageous in medium to hard formations, directional drilling, and heterogeneous intervals. In very soft, homogeneous formations, 3-blade bits may sometimes be preferred for their aggressiveness.

3. How do 5-blade PDC bits impact overall drilling costs?

Although 5-blade bits typically have a higher initial cost, their extended bit life, consistent performance, and reduced non-productive time often result in lower overall drilling costs, especially in challenging formations or long horizontal sections.

4. Can 5-blade PDC bits be customized for specific drilling conditions?

Yes, 5-blade PDC bits can be customized to meet specific project requirements. Factors such as cutter size, blade profile, and hydraulic design can be optimized for particular formation characteristics and operational parameters.

5 Blades Steel Body High Performance PDC Rock Drill Bits Manufacturer | HNS

Looking for a reliable supplier of high-quality PDC drill bits? Shaanxi Hainaisen Petroleum Technology Co., Ltd. is your go-to manufacturer for innovative drilling solutions. Our 5 Blades Steel Body High Performance PDC Rock Drill Bits are engineered to deliver superior performance across a wide range of drilling applications. With our commitment to quality and customer satisfaction, we ensure that each bit meets the highest industry standards.

To learn more about our products or to discuss your specific drilling requirements, please don't hesitate to contact us at hainaisen@hnsdrillbit.com. Our team of experts is ready to provide you with tailored solutions that will optimize your drilling operations and drive your project success.

References

1. Smith, J. et al. (2021). "Comparative Analysis of 5-Blade and 3-Blade PDC Bit Performance in Diverse Formation Types." Journal of Petroleum Technology, 73(5), 62-70.

2. Johnson, R. (2020). "Advancements in Steel Body PDC Bit Design for Enhanced Durability and Performance." SPE Drilling & Completion, 35(3), 301-315.

3. Lee, M. and Williams, S. (2019). "Hydraulic Optimization of Multi-Blade PDC Bits for Improved Cuttings Transport and Bit Cooling." IADC/SPE Drilling Conference and Exhibition, SPE-194129-MS.

4. Thompson, K. (2022). "Impact of Blade Configuration on PDC Bit Stability and Directional Control in Horizontal Drilling Applications." Journal of Natural Gas Science and Engineering, 98, 104359.

5. Garcia, A. et al. (2018). "Economic Evaluation of PDC Bit Selection Based on Performance and Durability in Various Rock Formations." SPE Annual Technical Conference and Exhibition, SPE-191439-MS.

6. Brown, T. (2023). "Next-Generation PDC Cutter Technology: Enhancing Bit Performance in High-Temperature and Abrasive Environments." Offshore Technology Conference, OTC-32154-MS.