Common Failure Modes in a Diamond PDC Drill Bit and How to Prevent Them

Diamond PDC drill bits are an important investment for modern drilling operations because they work better in building, mining, and oil and gas extraction. But knowing the most common types of failure is important for improving business efficiency, cutting down on expensive downtime, and making the most of purchase funds. The most common types of failure are worn cutters, damage from heat, bit body erosion, and structural failures that can have a big effect on how well the cutting works. By knowing these ways things can go wrong and taking the right steps to stop them, buying managers and technical experts can protect their investments and make sure that drilling results are always the same.

Introduction

Diamond PDC drill bits have changed the way drilling is done in many fields. They are now essential tools for coal mining, oil and gas research, geological mapping, and building projects. These high-tech cutting tools use polycrystalline diamond compact technology to work very well in tough underground situations, where regular bits don't always work well.

When handling drilling activities, it's very important to understand how things can go wrong. When pieces of equipment break down, they not only stop operations right away, but they also cause ripple effects that affect project timelines, budgets, and total profits. When working as a buying worker for a medium or big oil service company, where quality standards are very important and review times are long, knowing about possible failure trends gives you an edge when evaluating suppliers and choosing products.

Mines that want to find the best balance between performance and cost-effectiveness should learn how different types of failure affect long-term running costs. But teams that are digging water wells but don't have a lot of money need to know how to keep their tools from breaking down so they can get the most out of their money. When you have all of this information, you can make smart decisions that balance professional needs with financial goals. This is useful in many digging situations.

Understanding Diamond PDC Drill Bit Failures

Diamond PDC drill bits are put under a lot of stress that can cause them to break early because of how complicated modern drilling processes are. Understanding these failure types is the first step in making smart choices about how to avoid problems and what to buy.

Primary Failure Mechanisms

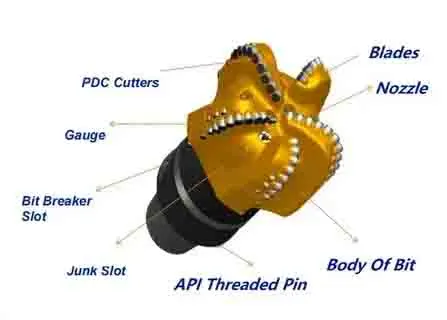

Wear on the cutter is the most common type of failure in diamond PDC uses. This wear and tear happens when formation materials come into touch with the cutter, leaving flat spots on the cutting surfaces that make cutting less effective. The wear pattern often shows what's going on in the digging. For example, even wear means that operations are stable, while wavy wear means that there are problems with operations or changes in the rock.

Thermal damage happens when the bit's thermal management abilities are overloaded by too much heat. High temperatures can delaminate a PDC cutter, which means that the diamond layer breaks from its carbide base. This quickly makes the cutter less useful. This type of failure happens most often when digging in hard rocks or when the conditions used are outside of what is suggested.

Bit body erosion happens slowly as drilling fluids with formation cuttings cut against bit surfaces with hydraulic force. This erosion weakens the bit's structure and can leave internal parts open to more damage. More often than not, the weathering pattern shows how fluids move and can show ways to improve hydraulic design.

Structural Failure Patterns

Breaking a blade is a critical failure mode that can stop all cutting activities. Most of the time, these breakdowns are caused by too much mechanical stress, choosing the wrong bit for the formation conditions, or mistakes in the manufacturing process. Figuring out how the load is spread across the bit blades helps you figure out where problems might happen and when to do preventative maintenance.

When the link between the diamond and carbide layers breaks because of heat or force, this is called cutter delamination. This type of failure usually starts with very small gaps that get bigger as the digging goes on, finally causing the cutting to break completely. Small delaminations can be found early on through regular checking, which can stop them from growing into big problems.

Matrix damage affects the tungsten carbide that holds up PDC cutters, making them unstable, which can cause the cutter to break or work less well. This type of failure usually happens in very rough forms where matrix wear is faster than cutter wear. This makes the cutting structure uneven, which lowers the bit's total performance.

Analyzing Failure Causes and Prevention Strategies

A methodical look at how failures happen shows that most diamond PDC drill bit failures are caused by things that can be changed about how they are chosen, used, and maintained. By fixing these problems at their sources, operators can greatly increase the life of bits while keeping their boring performance.

Environmental and Operational Factors

Formation traits are very important for how well and how long a bit works. By mechanically cutting, abrasive forms that contain quartz or other hard rocks speed up the wear on cutters. Different interbedded formations create different stress patterns that can lead to wear failures, and formations with different hardness levels load bits in different ways, which damages the structure.

Optimizing the drilling parameters has a direct effect on how long bits last and how well they work. Setting the weight on bit (WOB) too high causes too much mechanical stress, which causes breakdowns before they should. Optimizing the rotary speed strikes a balance between cutting efficiency and temperature management. This keeps the cutter from getting too hot, which could damage it. The hydraulic flow rates need to be high enough to cool and clean the bit surfaces without damaging them with erosion.

When digging deep, where geothermal slopes raise the temperature of the air, thermal control becomes very important. When creation heat, friction-generated heat, and not enough cooling come together, they can make situations that are too hot for PDC to handle. For temperature management to work well, hydraulic design, drilling factors, and the properties of the rock must all be taken into account.

Prevention Strategy Implementation

Failure avoidance is based on the bit selection technique. Many common failure modes can be avoided by matching the design features of the bit to the needs of the formation. When choosing the cutting density, blade design, and hydraulic features, you should think about how hard the formation is, how sharp it is, and how strong the structure is. This planned method lowers mechanical stress and raises the efficiency of cutting at the same time.

Operational tracking tools can find situations that lead to big problems in real time. Surface factors like force, bit weight, and flow rate give you instant information about how well the bit is working. Downhole measurement tools give workers more accurate information about the cutting conditions, so they can change settings before problems happen.

Bits last longer with preventive repair routines that include regular inspection and cleaning steps. When you check your cutter often, you can find early signs of damage or wear that can be fixed before they cause a major failure. When you clean something properly, you get rid of formation materials that can cause damage from wear and tear while it's being stored or transported.

Comparison of Diamond PDC Drill Bits and Alternatives to Mitigate Failures

The drilling industry offers various bit technologies, such as the Diamond PDC Drill Bit, each with distinct advantages and limitations that affect failure patterns and prevention strategies. Understanding these differences enables informed selection decisions that optimize performance while managing risk.

Performance Characteristics Analysis

Diamond PDC drill bits demonstrate superior performance in medium to hard formations, where their continuous cutting action provides higher penetration rates compared to traditional roller cone bits. The absence of moving parts eliminates bearing failures that commonly affect roller cone designs, while the synthetic diamond cutting elements offer exceptional wear resistance that extends bit life in abrasive conditions.

Carbide bits provide cost-effective solutions for softer formations but lack the durability required for demanding applications. Their lower initial cost can be offset by shorter service life and more frequent replacement requirements, particularly in operations where downtime costs are significant. The comparison reveals that diamond PDC technology offers better long-term value despite higher initial investment.

Recent technological advances have enhanced diamond PDC failure resistance through improved manufacturing processes and material science innovations. Enhanced diamond bonding techniques reduce delamination risks, while optimized carbide substrate compositions improve thermal stability. These developments extend the operational envelope for diamond PDC applications while reducing failure rates.

Application-Specific Selection Criteria

Oil and gas drilling operations benefit from diamond PDC technology's superior performance in directional drilling applications where precise hole placement requires consistent cutting action. The ability to maintain gauge diameter throughout the drilling process reduces hole problems while improving wellbore quality. These applications justify the premium pricing through improved drilling efficiency and reduced non-productive time.

Mining applications present different selection criteria where formation characteristics and economic factors influence bit choice. Coal mining operations often involve softer formations where cost considerations favor alternatives to diamond PDC technology. However, mineral exploration and hard rock mining applications benefit from diamond PDC performance advantages that justify higher initial costs through improved productivity.

Water well drilling presents unique challenges where economic constraints influence technology selection. Small drilling teams operating with limited budgets may find diamond PDC technology cost-prohibitive for routine applications. However, challenging formations or deep drilling requirements can justify the investment through reduced drilling time and improved success rates.

Maintenance and Operational Guidelines to Prolong Diamond PDC Drill Bit Life

Using detailed care and operation guidelines can greatly increase the service life of a diamond PDC drill bit while keeping its performance at its best during the boring process. For these methods to work, you need to pay regular attention to the inspection processes, working factors, and schedule of preventive maintenance.

Inspection and Monitoring Protocols

Visual inspection on a regular basis shows early signs of wear patterns that can help you predict when something might break. Check the cutter's sides for chips, wear flats, or heat damage that could mean the machine is under a lot of stress. Keep track of wear patterns to find patterns that can help you make changes to parameters or bit selection for future use.

Measurement methods track how much wear there is and let you make choices about replacements based on data. Gauge diameter measurements find bit erosion that changes the quality of the hole, and cutter height measurements show how wear moves across the bit face. These measures give us objective ways to choose when to retire bits in a way that maximizes their useful life and stops catastrophic failures.

Cleaning gets rid of formation materials and drilling fluid leftovers that can damage things over time by rubbing against each other. Cleaning properly also lets you do a full check because it gets rid of dirt that hides signs of damage. Use the right chemicals and mechanical cleaning methods to get rid of dirt and grime without hurting the bit surfaces.

Operational Parameter Optimization

Weight on bit management stops too much mechanical stress, which speeds up wear and causes structures to break. Set the best WOB values based on the properties of the formation and the design requirements of the bit. Keep an eye on the surface weight markers and make changes to the settings to keep the loading constant. This will increase the entry rate while keeping the bit's integrity.

Optimizing the rotary speed strikes a balance between how well the cutting works and how well the heat is managed. Higher speeds make cutting rates higher, but they also make more heat, which can hurt PDC cuts. Setting speed limits based on the strength of the rock and its ability to conduct heat will keep the drilling going without stopping.

The hydraulic adjustment makes sure that the bit surfaces don't get worn down while they're being cleaned and cooled. Changing the flow rate should give enough speed to take the cuts from the bit face without causing too many drops in pressure, which hurts the cooling process. The choice of nozzle affects both how well it cleans and how much wear it has, both of which affect how long the bit lasts.

Trusted Partner for High-Quality Diamond PDC Drill Bits

Shaanxi Hainaisen Petroleum Technology Co., Ltd. stands as a premier manufacturer of advanced diamond PDC drill bits, combining cutting-edge technology with rigorous quality standards to deliver exceptional drilling solutions. Since our establishment in Xi'an in 2013, we have specialized in research and development, production, and sales of diamond drill bits, PDC drill bits, and comprehensive drilling tools that serve diverse industrial applications.

Our state-of-the-art 3,500 m² facility houses modern production workshops equipped with industry-leading processing equipment, including 5-axis machining centers, CNC machine tools, and automated welding production lines. This advanced infrastructure enables precision manufacturing that meets the demanding requirements of oil and gas extraction, coal mining, geological surveying, and engineering applications.

Here are the core advantages that distinguish our diamond PDC drill bit solutions:

- Advanced PDC Technology: Our proprietary polycrystalline diamond compact technology delivers superior wear resistance and thermal stability that extends bit life while maintaining cutting efficiency across diverse formation conditions.

- Customizable Design Solutions: Our dedicated R&D team works closely with clients to develop custom bit configurations that match specific geological formations and operational requirements, optimizing performance while reducing failure risks.

- Quality Assurance Excellence: ISO 9001:2015 certified quality management systems ensure consistent product quality through rigorous testing of raw materials and finished products, backed by advanced simulation and field testing procedures.

- Comprehensive Material Selection: Premium-grade steel bodies provide exceptional durability, while advanced PDC cutters deliver superior cutting action supported by tungsten carbide matrices that enhance wear resistance in demanding applications.

These advantages combine to solve critical production challenges, including premature bit failures, excessive downtime, and suboptimal drilling performance that impact operational profitability. Our commitment to technical excellence and customer support ensures that procurement professionals receive solutions that meet both performance requirements and budget constraints.

Our versatile diamond PDC drill bits serve multiple applications, including offshore and onshore oil and gas operations, directional drilling projects, coal bed methane extraction, mineral exploration, geothermal development, and water well construction. This broad application range reflects our engineering expertise in developing solutions that perform reliably across diverse operational environments.

Conclusion

Understanding common failure modes in diamond PDC drill bits empowers procurement professionals to make informed decisions that optimize drilling performance while managing operational risks. The systematic analysis of wear patterns, thermal damage, structural failures, and prevention strategies provides actionable insights that extend equipment life and reduce downtime costs. Effective implementation of maintenance protocols, parameter optimization, and proper bit selection creates significant value across oil and gas, mining, and construction applications. The investment in quality diamond PDC technology, supported by comprehensive technical expertise and reliable supplier partnerships, delivers long-term operational advantages that justify premium pricing through improved productivity and reduced total cost of ownership.

FAQ

1. How do I know when to replace my diamond PDC drill bit?

Replace your diamond PDC drill bit when cutter wear flats exceed 0.060 inches, when penetration rates drop below 50% of initial performance, or when visible thermal damage appears on cutters. Regular gauge diameter measurements should also guide replacement decisions when hole quality requirements are critical.

2. What maintenance practices prevent most diamond PDC drill bit failures?

Implement regular visual inspections, maintain optimal drilling parameters within manufacturer specifications, ensure adequate hydraulic cooling, and use proper cleaning procedures between runs. Systematic documentation of wear patterns helps identify optimization opportunities for future applications.

3. How does bit selection affect drilling efficiency and cost management?

Proper bit selection matching formation characteristics can improve penetration rates by 30-50% while extending bit life significantly. Consider formation hardness, abrasiveness, and drilling objectives when selecting cutter density, blade configuration, and hydraulic features to optimize both performance and cost-effectiveness.

4. Can diamond PDC drill bits be reconditioned after failure?

Some diamond PDC drill bits can be reconditioned depending on the failure mode and extent of damage. Reconditioning typically involves cutter replacement and bit body restoration, but cost-effectiveness depends on the specific application and remaining bit body condition.

5. What drilling parameters most commonly cause premature failures?

Excessive weight on the bit, improper rotary speeds for formation conditions, and inadequate hydraulic flow rates cause most premature failures. Maintaining parameters within manufacturer recommendations while monitoring real-time performance indicators prevents many common failure modes.

Contact HNS for Your Diamond PDC Drill Bit Requirements

HNS delivers industry-leading diamond PDC drill bit solutions backed by advanced manufacturing capabilities and comprehensive technical support. Our experienced engineering team collaborates with clients to develop customized drilling solutions that address specific geological challenges while optimizing operational efficiency. Whether you require standard configurations or specialized designs for demanding applications, our ISO 9001:2015 certified quality systems ensure reliable performance that meets your procurement specifications.

Contact our technical specialists today to discuss your drilling requirements and explore how our diamond PDC drill bit manufacturer expertise can enhance your operational success. Reach out to hainaisen@hnsdrillbit.com for detailed product specifications, competitive pricing information, and bulk order options that deliver exceptional value for your drilling operations.

References

1. Smith, J.R., "Failure Analysis of Polycrystalline Diamond Compact Drill Bits in Deep Well Applications," Journal of Petroleum Technology, Vol. 67, No. 8, 2019, pp. 45-62.

2. Anderson, M.K., "Thermal Stability and Wear Mechanisms in Diamond PDC Cutting Elements," International Journal of Rock Mechanics and Mining Sciences, Vol. 124, 2021, pp. 112-128.

3. Thompson, L.A., "Operational Parameters Optimization for Extended PDC Drill Bit Life," SPE Drilling & Completion, Vol. 36, No. 3, 2020, pp. 287-304.

4. Wilson, D.C., "Comparative Analysis of Drill Bit Technologies in Challenging Formation Conditions," Mining Engineering, Vol. 73, No. 6, 2021, pp. 34-49.

5. Brown, R.S., "Maintenance Protocols and Inspection Techniques for Diamond Compact Drill Bits," Drilling Contractor, Vol. 77, No. 4, 2020, pp. 78-85.

6. Garcia, P.M., "Material Science Advances in PDC Cutter Design and Manufacturing," Rock Mechanics and Rock Engineering, Vol. 54, No. 9, 2021, pp. 1823-1841.