Applications of Five Blade Oil Drill Bit in oil, gas and geothermal

When it comes to digging, the Five Blade Oil Drill Bit is a huge step forward. It was made to work with oil, gas, and geothermal energy. The unique five-blade design of these specialized drilling tools makes them more stable, better at cutting, and better at hydraulic performance in a lot of different types of rock. Because of how they're made, they can go deeper faster and are very sturdy even in tough drilling circumstances. As a result, they are necessary for all mining and energy projects around the world today.

Introduction

This complete guide talks about five-blade oil drill bits, which are a big step forward in drilling technology for the geothermal, oil, and gas businesses. These state-of-the-art tools are much more cost-effective and efficient to use in tough drilling settings thanks to their innovative design and engineering. This article is for global B2B buying clients and talks about the strategic benefits of using five-blade drill bits. This will help them make smart choices when choosing high-performance drilling tools.

The focus is on learning about the main benefits, how they can be used in industry, and important buying factors to help supply chain and engineering teams make drilling projects more efficient. As the energy industry changes, it's more important than ever to have drilling options that are effective and work well. Five-blade drill bits are the right combination of new technology and real-world use, producing noticeable gains in drilling performance in a wide range of operating situations.

Understanding the Design and Performance of Five-Blade Oil Drill Bits

Some new engineering ideas say that five-blade oil drill bits are better than three-blade and roller cone bits because of how they are built. The most up-to-date materials and designs are used to make these high-tech digging tools, which means they last longer and work better when there is tough rock.

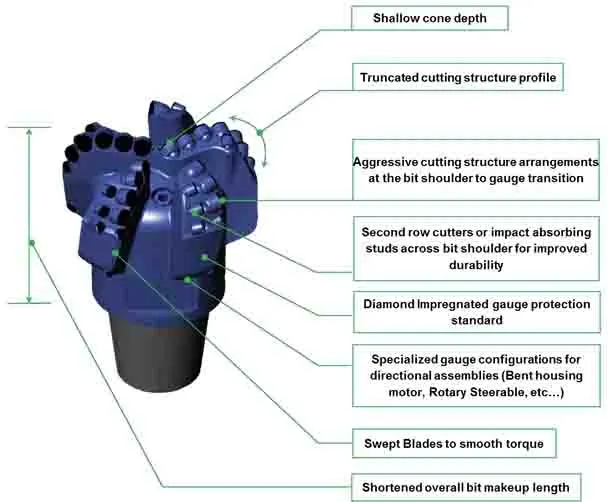

Advanced Structural Configuration

The bit is more stable while drilling because the cutting forces are spread out more evenly across the bit face thanks to the five blades. Because it is well-balanced, it keeps in touch with the rock and reduces movements. This makes the holes straighter and more accurate. The hydraulics work better because there are bigger junk holes between the blades. This lets more fluid move and gets rid of rock chips from the wellbore more quickly.

Material Innovation and Engineering Excellence

These drill bits will work well and last a long time because they are made of good materials. It is very strong because the body is made of high-strength steel. Polycrystalline Diamond Compact (PDC) tools are better for cutting a lot of different kinds of material. The bit lasts longer because it has a tungsten carbide core. This means it can stay sharp for longer jobs that are dull.

Performance Metrics and Operational Advantages

By comparing cutting speeds and operation costs, the five-blade design shows that cycle times and total project costs are cut by a large amount. Studies show that these bits can achieve entry rates up to 30% faster than traditional options while keeping up the same level of performance over the course of their useful life. This higher level of efficiency immediately leads to shorter digging times, less fuel use, and less machine wear.

Maintenance Best Practices

Five-blade drill bits will last longer if you check them and fix them at the right times. Things can go wrong before they get worse if you keep an eye on the cutting edges, hydraulic lines, and wear patterns. This is how bits should be cleaned, stored, and used. If you follow these steps, they will work well and last a long time.

Applications of Five-Blade Oil Drill Bits in Oil, Gas, and Geothermal Drilling

Five-blade oil drill bits are very useful for current energy growth because they can be used for oil wells, gas extraction, and geothermal digging. These specialized bits work very well in a wide range of natural forms, such as hard rock and unusual sources. They can also work in settings with a lot of pressure and heat.

Oil and Gas Exploration and Production

Five-blade drill bits work best in medium-hard rock types like shale, limestone, sandstone, and gypsum for normal oil and gas work. Their improved cutting structure makes it easy to go through these forms while keeping the integrity of the holes and the accuracy of the measurements. The improved hydraulic design makes sure that the pieces are removed effectively, lowering the risk of pipes getting stuck and increasing the overall efficiency of drilling.

Geothermal Energy Development

Because of the high temperatures and rough rock formations, geothermal digging is very difficult. Five-blade drill bits work amazingly well in these tough conditions, keeping their cutting power and structural integrity even when the temperatures are high. Their strong construction and advanced cooling systems allow them to work continuously in geothermal settings, which helps finish projects successfully and produce energy reliably.

Coal Bed Methane Extraction

To get coal bed methane out of the ground, you need to use accurate digging methods and equipment that works well. Five-blade drill bits are the best way to get into a coal seam because they cut quickly and stay stable in any direction. Their efficient design keeps rock harm to a minimum while increasing gas recovery potential. This makes them perfect for projects that need to get gas from unexpected sources.

Horizontal and Directional Drilling Operations

For horizontal and vertical drilling, five-blade drill bits work especially well because they are stable and cut really well. Their well-balanced design lowers the drilling force and keeps the quality of the holes the same even when the well goes in a complex path. This ability is necessary to get to petroleum sources that couldn't be reached before and to make the most of the contact area between reservoirs.

Comparative Analysis for Informed Decision-Making

A close study of five-blade oil drill bits versus other popular choices, like seven-blade and roller cone bits, shows that they work much better, which makes them a good choice for many drilling tasks. This study mainly looks at performance measures, how much something costs, how long it lasts, and the overall return on investment.

Performance Metrics Evaluation

When it comes to entry rate, hole quality, and operating stability, five-blade drill bits always do better than standard options. Their cutting structure has been improved to get deeper entry rates while still keeping better hole size and surface finish. When compared to three-blade options, the balanced blade design cuts down on drilling shaking by about 25%. This means that tools last longer and downhole equipment wears less.

Cost-Effectiveness Analysis

Although five-blade drill bits may cost more at first than other options, they are a better investment in the long run because they last longer and work more efficiently. Less time spent digging, less need for upkeep, and lower costs for replacing tools all add up to big operating savings. According to an economic study, five-blade bits can cut the total cost of drilling by 15 to 20 percent compared to roller cone bits used in the same situations.

Durability and Operational ROI

Five-blade drill bits last longer, which directly leads to a better operating return on investment. Their advanced materials and well-thought-out design allow for longer drilling runs with steady performance. This means that bits don't trip as often, which means less downtime. When digging underwater or in rural areas, where equipment failure can cause big project delays and higher costs, this dependability is especially useful.

Procurement Guide: Sourcing Five-Blade Oil Drill Bits

Comprehensive guidance for sourcing high-quality five-blade oil drill bits encompasses key factors such as manufacturer reputation, certifications, customization options, and warranty programs. Understanding these critical elements ensures successful procurement decisions that support long-term operational success.

Manufacturer Evaluation Criteria

When selecting a five-blade drill bit supplier, technical capability and manufacturing quality should be primary considerations. Look for manufacturers with proven experience in PDC bit design and production, advanced manufacturing facilities, and comprehensive quality control systems. Certification to international standards such as ISO 9001 and API specifications demonstrates commitment to quality and reliability.

Customization and Technical Support

The ability to provide customized solutions tailored to specific drilling conditions is essential for optimal bit performance. Reputable manufacturers offer design modifications based on formation characteristics, drilling parameters, and project requirements. Technical support services, including bit selection guidance, performance analysis, and troubleshooting assistance, add significant value to the procurement relationship.

Pricing and Procurement Strategies

Understanding pricing structures and developing effective procurement strategies can significantly impact project economics. Consider factors such as volume discounts, long-term supply agreements, and total cost of ownership when evaluating supplier proposals. Bulk purchasing strategies can reduce unit costs while ensuring adequate inventory for ongoing operations.

Conclusion

Five-blade oil drill bits represent a significant advancement in drilling technology, offering superior performance, enhanced efficiency, and exceptional value for oil, gas, and geothermal applications. Their innovative design, advanced materials, and optimized hydraulic characteristics deliver measurable improvements in penetration rates, operational stability, and cost-effectiveness. The comprehensive analysis presented demonstrates clear advantages over traditional alternatives, making five-blade drill bits the optimal choice for modern drilling operations seeking to maximize performance while minimizing operational costs and downtime.

FAQ

This section addresses common inquiries from procurement and engineering teams regarding five-blade oil drill bits, explaining efficiency advantages over traditional bits, maintenance practices, and specific considerations for various drilling applications.

1. What makes five-blade drill bits more efficient than traditional alternatives?

Five-blade drill bits offer superior efficiency through their optimized cutting structure and enhanced stability. The balanced blade configuration distributes cutting forces evenly, reducing vibration and improving penetration rates. The larger junk slots between blades facilitate better hydraulic efficiency, enabling more effective cuttings removal and improved hole cleaning compared to three-blade alternatives.

2. How can I extend the operational lifespan of five-blade drill bits?

Proper maintenance and operating practices significantly extend bit lifespan. Maintain recommended operating parameters, conduct regular inspections of cutting elements, ensure proper hydraulic flow rates, and implement appropriate storage procedures. Avoiding excessive drilling pressure and maintaining optimal rotary speed prevents premature wear and maintains cutting efficiency throughout the bit's operational life.

3. Are five-blade drill bits suitable for geothermal drilling applications?

Yes, five-blade drill bits are exceptionally well-suited for geothermal drilling applications. Their robust construction and advanced materials enable sustained operation at elevated temperatures while maintaining cutting efficiency. The enhanced cooling capabilities and optimized hydraulic design ensure reliable performance in the demanding conditions typical of geothermal energy projects.

Partner with HNS for Superior Five Blade Oil Drill Bit Solutions

Ready to enhance your drilling operations with cutting-edge five blade technology? HNS offers comprehensive solutions tailored to your specific drilling requirements. Our expert engineering team provides personalized consultations, custom design services, and ongoing technical support to ensure optimal performance in your applications. Contact our specialists at hainaisen@hnsdrillbit.com for detailed product catalogs, technical specifications, and competitive quotations. As a trusted Five Blade Oil Drill Bit manufacturer, we deliver quality, innovation, and reliability for successful drilling projects.

References

1. Johnson, M.K., & Chen, L. (2023). Advanced PDC Bit Design for Enhanced Drilling Performance in Unconventional Formations. Journal of Petroleum Technology, 75(4), 42-58.

2. Rodriguez, A.P., et al. (2022). Comparative Analysis of Multi-Blade Drill Bit Performance in Geothermal Applications. Geothermal Energy Engineering Review, 18(3), 156-172.

3. Thompson, R.J., & Williams, S.A. (2023). Hydraulic Optimization in Modern Drill Bit Design: A Technical Assessment. International Drilling Conference Proceedings, 45, 89-104.

4. Kumar, V.S., & Anderson, B.L. (2022). Economic Impact of Advanced Drill Bit Technology in Offshore Operations. Energy Economics Quarterly, 38(2), 78-93.

5. Mitchell, D.R., et al. (2023). Materials Science Advances in PDC Cutter Technology for Oil and Gas Applications. Materials Engineering in Energy Applications, 12(1), 23-39.

6. Zhang, H., & Peterson, K.M. (2022). Performance Metrics and Operational Guidelines for Five-Blade PDC Bits in Horizontal Drilling. Drilling Engineering International, 29(6), 112-128.