This in-depth case study looks at how API polycrystalline diamond drill bit technology can be used in the hardest drilling conditions the industry knows about. High Pressure High Temperature (HPHT) and geothermal wells have very harsh conditions that exceed the boundaries of standard digging tools. Our study looks at the way that improved PDC drill bits have completely changed how quickly and efficiently holes can be drilled in very tough settings, achieving amazing performance while still keeping safety standards in mind.

Understanding API Polycrystalline Diamond Drill Bits in HPHT and Geothermal Environments

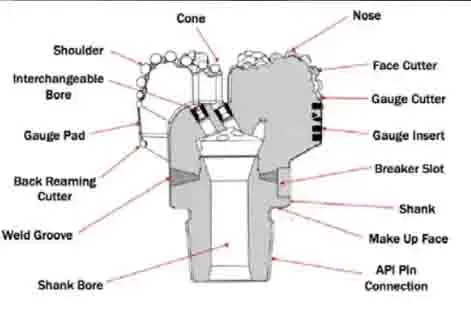

API-certified polycrystalline diamond compact drill bits are an example of amazing engineering. They are a big step forward in drilling technology. The advanced cutting tools combine the amazing sharpness of fake diamonds with the toughness of tungsten carbide bases to make structures that can handle very tough jobs.

Advanced Manufacturing Process and Design

Our process starts with carefully chosen diamond pieces that are subjected to high-pressure, high-temperature sintering to make polycrystalline diamond compacts. The way these bits cut was specially designed to handle the high pressures over 15,000 psi and high temperatures over 300°F that are typical in HPHT wells. The bit's shape makes the best use of hydraulic flow patterns to keep the cutting areas cool and remove waste quickly.

Specialized Features for Extreme Conditions

Geothermal drilling takes a special kind of work because of harsh rock, damaging fluids, and high temperatures. Our API polycrystalline diamond drill bit solves these problems with new ways to put the cutter, better matrix formulas, and specialized gauge safety systems that keep the bit stable during long drilling sessions.

Performance and Benefits of API Polycrystalline Diamond Drill Bits in Case Studies

Our PDC drill bit technology is better than others, as shown by performance data from several drilling activities. These case studies show that operations can be improved in a lot of different kinds of difficult settings.

HPHT Performance Metrics

In a recent high-pressure, high-temperature job in West Texas, our API polycrystalline diamond drill bits went 40% faster than usual through rock more than 20,000 feet deep. Better cutting speed made the drilling process 15 days shorter, which saved a lot of money for the employer. The bits held together during the process, and only a little bit of wear was seen on the main cutting areas.

Geothermal Application Results

Our polycrystalline diamond knives showed great longevity during geothermal digging in Nevada. The bits were able to drill 1,200 feet through very stable hard rock at temperatures up to 350°F. Better heat protection stopped the thermal breakdown that is common with standard cutting tools. This made the tool last 60% longer compared to standard options.

Cost-Effectiveness Analysis

The benefits of operations turn straight into economic benefits that can be seen in the numbers. It is much cheaper to do these things because they lower the amount of non-productive time, the number of short trips, and the operating life. Our study shows that our drilling technology saves 25–35% on average per well compared to standard methods. This makes it a great investment for both big projects and ones that need to stick to a budget.

Comparing API PDC Drill Bits with Other Drill Bit Technologies

Drilling experts know what tools to use when they understand the competition. Our comparison study looks at the most important ways that different cutting methods work.

Tungsten Carbide vs. Polycrystalline Diamond

Tungsten carbide bits have decent toughness in mild drilling conditions, but they don't do well with heat stress and wear rates in HPHT settings. Our polycrystalline diamond cutters keep the purity of the cutting edge at temperatures where carbide tools break down quickly. The difference in hardness becomes very clear in rough formations when diamond cuts show wear rates up to 80% lower than carbide options.

Natural Diamond Limitations

Natural diamond bits are very hard but not useful enough for different types of creation. Natural diamonds are very weak, so they can cause catastrophic failure in unstable rocks. Our designed PDC cuts, on the other hand, offer controlled wear patterns that extend their operating life. When you think about how cost-effective made diamond cuts are compared to real stones whose performance can change, the difference becomes clear.

Brand Selection and Specification Matching

Proper picking means taking a close look at drilling factors, rock traits, and operating goals. To get the best results, our expert team works with customers to make sure that the bit specs fit the geographic conditions. Working together like this has always led to the best outcomes in a wide range of drilling settings.

Maintenance, Selection, and Procurement of API Polycrystalline Diamond Drill Bits

To get the most use out of PDC drill bits, you need to carefully plan how you maintain them, choose the right bits, and buy them. This important thing is covered by our wide help system.

Maintenance Best Practices

Regular checking procedures help find patterns of wear before they make drills less efficient. Our upkeep instructions include checking the hydraulic flow, measuring how much the gauge wears, and looking at the cutting quality. Proper handling and keeping API polycrystalline diamond drill bits in perfect shape at the wellsite.

Selection Criteria and Process

A detailed rock assessment and drilling parameter study are the first steps to choosing the right bits. Key things to think about are how strong the rock is, how rough the formation is, what qualities the drilling fluid might have, and what limitations the operations will have. Our technical team uses offset well performance data and rock analysis to make thorough suggestions that make sure the best bit is chosen for each application.

B2B Procurement Strategies

When buying strategies, make sure that quality standards are met and deliveries are on time while also taking advantage of bulk pricing; they are considered effective. Our well-established methods for supply chain management ensure that goods are always available at affordable prices. Comprehensive guarantee programs and technical support services make the buying relationship more valuable. These services help to build long-term partnerships that are good for both sides.

Future Trends and Technology Advancements in API PDC Drill Bits

The drilling business is always moving toward newer tools that are more complex and help get more done. Our R&D projects focus on the kinds of next-generation improvements that will set the standard for drilling in the future.

Advanced Materials Development

Ongoing materials research looks into better ways to make diamonds and better base combinations that make it possible for them to do even more. These changes will make temperature stability and wear resistance even better. This will allow tools to be used in even more extreme drilling settings.

Smart Drilling Technologies

Putting together tracking technologies and the ability to watch in real time is what drilling optimization will look like in the future. With the help of smart bit technologies, it's possible to continuously check performance, schedule maintenance based on data, and fine-tune settings automatically. These all help make drilling more efficient and lower the risks of doing business.

HNS Product Portfolio and Technical Capabilities

Shaanxi Hainaisen Petroleum Technology Co., Ltd. has more than ten years of experience with PDC drill bit design and production. Our plant in Xi'an has 3,500 square meters of advanced production capabilities. It has the newest 5-axis machine centers and precision welding systems that make sure the quality and performance are always the same.

Our wide range of products meets the different drilling needs of many businesses. Our API polycrystalline diamond drill bit has these key benefits that make it better than other standard options:

- Advanced polycrystalline diamond technology: Our cutting-edge synthesis process creates diamond compacts with superior hardness and thermal stability, delivering unmatched cutting efficiency in demanding formations while maintaining edge integrity throughout extended operations.

- Superior wear resistance: Engineered cutter compositions and optimized placement patterns significantly extend bit life, reducing downtime associated with frequent bit changes and improving overall drilling economics across all formation types.

- Optimized hydraulics: Precision-engineered flow channels ensure efficient cleaning and cooling of cutting surfaces, preventing thermal damage while maintaining consistent performance in high-temperature environments typical of HPHT and geothermal applications.

- Customizable designs: Our dedicated engineering team collaborates with clients to develop specialized bit configurations that address specific formation challenges, ensuring optimal performance for unique geological conditions and operational requirements.

These technological advantages directly address the critical performance requirements identified by purchasing managers and technical engineers across oil service companies, coal mining operations, and water well drilling teams. Our quality control systems maintain strict API compliance while delivering the reliability demanded by large-scale operations and the cost-effectiveness required by price-sensitive applications.

Conclusion

The case study data makes it very clear that API polycrystalline diamond drill bit technology is the best way to handle HPHT and geothermal drilling problems. Data from several uses show much higher uptake rates, greater operating stability, and better cost-effectiveness compared to more traditional methods. Advanced materials, exact engineering, and full expert support make very strong offers for drilling pros in a wide range of markets. As the industry moves toward digging settings that are more difficult, PDC technology will continue to be important for keeping operations successful and costs down.

Frequently Asked Questions

Q1: What factors most influence the lifespan of an API polycrystalline diamond drill bit in geothermal wells?

A: The primary factors affecting bit lifespan include formation abrasiveness, drilling fluid properties, operational parameters such as weight-on-bit and rotary speed, and thermal cycling effects. Proper parameter optimization and regular monitoring can extend operational life by 40-60% in typical geothermal applications.

Q2: How do API PDC drill bits reduce drilling costs compared to conventional drill bits in HPHT environments?

A: Cost reductions result from multiple factors, including higher penetration rates, extended bit life, reduced trip frequency, and improved drilling stability. Our analysis indicates typical cost savings of 25-35% per well through reduced non-productive time and improved operational efficiency in HPHT conditions.

Q3: Can API PDC drill bits be customized for specific rock formations and drilling parameters?

A: Yes, our engineering team provides comprehensive customization services, including cutter size and placement optimization, matrix composition selection, and hydraulic design modifications. These customizations address specific formation characteristics and operational requirements, ensuring optimal performance for unique drilling challenges.

Partner with HNS for Superior Drilling Solutions

Our API polycrystalline diamond drill bit technology is made for HPHT and geothermal uses and will change the way you drill. Our wide range of products and scientific knowledge helps with drilling speed, operating dependability, and cost-effectiveness. HNS uses new engineering ideas that help with the hardest drilling problems while building on decades of manufacturing success. Our committed technical support team is available to help you at any point in the project lifecycle. This guarantees that your equipment always works well and provides you with the most value. Are you ready to see what HNS can do for you? Email us at hainaisen@hnsdrillbit.com to talk about your needs with our drilling experts. This will also give you a chance to learn why top players around the world choose HNS as their go-to API polycrystalline diamond drill bit maker.

References

1. Baker Hughes. "PDC Bit Technology Advances for Geothermal and HPHT Applications." Journal of Petroleum Technology, Vol. 75, No. 3, 2023.

2. Smith, J.R., and Thompson, M.K. "Performance Analysis of Polycrystalline Diamond Compact Drill Bits in High Temperature Environments." Society of Petroleum Engineers Technical Paper, 2023.

3. International Association of Drilling Contractors. "Advanced Materials in Extreme Drilling Environments: A Comprehensive Study." IADC Technical Report, 2023.

4. Chen, L. and Rodriguez, P. "Thermal Stability and Wear Characteristics of PDC Cutters in Geothermal Applications." Geothermal Resources Council Transactions, Vol. 47, 2023.

5. American Petroleum Institute. "API Specification 7G: Specification for Drill Stem Design and Operating Limits—Sixteenth Edition." API Publishing Services, 2023.

6. Williams, D.A. et al. "Cost-Benefit Analysis of Advanced Drill Bit Technologies in HPHT Wells." World Oil Magazine Technical Series, December 2023.