Steel vs. Matrix: Durability in Extreme Conditions

When comparing drill bit materials for hard rock formations, the debate often centers around steel body versus matrix body bits. While both have their merits, steel body PDC bits have distinct advantages in extreme drilling conditions:

Superior Impact Resistance

Steel body PDC drill bits are the best at withstanding the high impact forces that come up when digging in hard rock. Steel is better at absorbing and spreading shock loads than matrix materials because it is flexible. This trait is especially useful when working with broken or interbedded formations, where quick changes in rock hardness can do a lot of damage to bits.

Enhanced Thermal Stability

Because of the pressure, hard rock digging often makes a lot of heat. Steel body bits are better at transferring heat than matrix bodies, so they can get rid of heat more quickly. This better heat control helps keep cutters from breaking down too quickly and increases the bit's general life in hot downhole conditions.

Flexibility in Design

Because the body is made of steel, bit design is more flexible, so blade configurations and cutter settings can be made to work best. Because they are flexible, engineers can make Steel Body PDC Drill Bits that are better suited to certain formation problems. This makes drilling more efficient and lowers vibrations in hard rock situations.

Ease of Repair and Maintenance

In the event of damage, steel body bits are generally easier to repair and maintain compared to matrix body alternatives. This characteristic can lead to significant cost savings and reduced downtime, especially in remote drilling locations where bit replacement may be challenging.

Optimizing Cutting Structures for Hard Rock Penetration

The effectiveness of Steel Body PDC Drill Bits in hard rock formations is largely attributed to their optimized cutting structures. Several key features contribute to their superior performance:

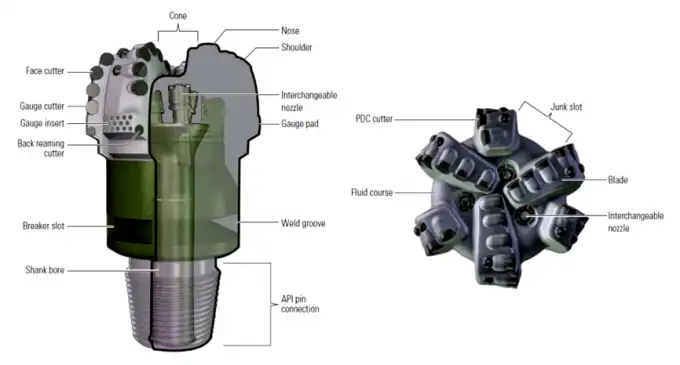

Advanced Cutter Technology

Modern steel body PDC bits utilize state-of-the-art polycrystalline diamond compact cutters. These cutters are engineered with enhanced thermal stability and abrasion resistance, allowing them to maintain their sharp cutting edge even under the extreme conditions encountered in hard rock drilling.

Strategic Cutter Placement

The design of steel body PDC bits allows for precise cutter positioning and orientation. This strategic placement optimizes the bit's cutting action, ensuring efficient rock removal while minimizing wear on individual cutters. The result is a more balanced and stable drilling process, even in heterogeneous hard rock formations.

Specialized Blade Designs

Steel body construction enables the implementation of innovative blade designs that enhance drilling performance in hard rock. These may include: - Spiral blade configurations for improved stability and reduced vibration - Tapered blade profiles for better weight distribution and penetration rates - Reinforced blade structures to withstand high lateral forces in directional drilling

Optimized Hydraulics

Efficient hole cleaning is crucial in hard rock drilling to prevent bit balling and maintain high penetration rates. Steel Body PDC Drill Bits feature carefully engineered hydraulic channels and nozzle placements that optimize fluid flow across the bit face. This enhanced hydraulic design ensures effective cuttings removal and proper cooling of the PDC cutters, contributing to sustained drilling performance in challenging formations.

Cost-Efficiency: Long-Term Benefits of Steel PDC Bits

While the initial cost of Steel Body PDC Drill Bits may be higher than some alternatives, their long-term economic benefits make them an attractive choice for hard rock drilling operations:

Increased Rate of Penetration (ROP)

The optimized cutting structure and durable steel body allow these bits to maintain higher penetration rates in hard rock formations. This increased ROP translates to faster drilling times and reduced overall project duration, resulting in significant cost savings on rig time and associated expenses.

Extended Bit Life

The combination of a robust steel body and advanced PDC cutter technology contributes to a longer bit life in abrasive hard rock environments. This extended durability means fewer trips out of hole for bit replacement, leading to decreased nonproductive time and lower overall bit consumption over the course of a drilling program.

Improved Drilling Efficiency

Steel body PDC bits offer enhanced stability and reduced vibration during drilling operations. This improved performance leads to: - Better directional control in deviated wellbores - Reduced risk of premature bit failure or damage - More consistent weight-on-bit and torque readings, allowing for optimized drilling parameters

Versatility Across Formation Types

The adaptable nature of steel body PDC bit designs allows for their use across a range of formation types, from medium-hard to extremely hard rocks. This versatility can reduce the need for multiple bit changes when drilling through interbedded formations, further contributing to operational efficiency and cost savings.

Lower Total Cost of Ownership

When considering the cumulative benefits of increased ROP, extended bit life, and improved drilling efficiency, Steel Body PDC Drill Bits often result in a lower total cost of ownership compared to alternative bit types. This cost-effectiveness is particularly pronounced in challenging hard rock drilling projects where bit performance directly impacts overall project economics.

Conclusion

Choosing Steel Body PDC Drill Bits for hard rock formations offers a compelling combination of durability, performance, and cost-efficiency. Their ability to withstand extreme conditions, coupled with optimized cutting structures and long-term economic benefits, makes them an ideal choice for operators facing challenging geological environments. As drilling technology continues to advance, Steel Body PDC Drill Bits supplier ensures they remain at the forefront of innovation, providing reliable solutions for the most demanding hard rock drilling applications.

Are you ready to experience the benefits of steel body PDC drill bits in your hard rock drilling operations? Look no further than Shaanxi Hainaisen Petroleum Technology Co., Ltd. With our expertise in drill bit design and manufacturing, we offer customized solutions to meet your specific drilling challenges. Our state-of-the-art facility and dedicated R&D team ensure that you receive top-quality products tailored to your needs. Whether you're in oil and gas extraction, coal mining, or geological surveying, our steel body PDC drill bits are designed to deliver superior performance and cost-efficiency. Don't let hard rock formations slow down your project – contact us today to explore how our innovative drill bit technology can revolutionize your drilling operations.

FAQ

1. What makes steel body PDC drill bits suitable for hard rock formations?

Because they are better at resisting pressure, staying stable at high temperatures, and having cutting structures that work best, steel body PDC drill bits are perfect for hard rock formations. The steel body is strong and can be designed in a variety of ways. The modern PDC cutters make it easy to remove rocks even in tough situations.

2. How do steel body PDC bits compare to matrix body bits in terms of performance?

Most of the time, steel body PDC bits are better at resisting impacts and transferring heat than matrix body bits. They are also easier to create because the blades and cutters can be placed in ways that are best for the hard rock drilling tasks at hand.

3. What are the long-term cost benefits of using steel body PDC drill bits?

Due to their higher rate of entry, longer bit life, and better drilling efficiency, steel body PDC drill bits often have a lower total cost of ownership. These things help hard rock drilling projects save money by cutting down on rig time, bit trips, and other costs.

4. Can steel body PDC drill bits be used in different types of hard rock formations?

Yes, steel body PDC drill bits are flexible and can be made to work well in a wide range of hard rock types, from medium-hard to very hard. Because they are flexible, they can be used to drill through interbedded rocks with different amounts of hardness.

Steel Body PDC Drill Bit Manufacturers | HNS

Looking for high-quality steel body PDC drill bits for your hard rock drilling projects? Shaanxi Hainaisen Petroleum Technology Co., Ltd. is your trusted partner in drill bit manufacturing. Our advanced production facilities and experienced R&D team ensure that you receive top-of-the-line products designed to meet your specific drilling requirements. Whether you need bits for oil and gas extraction, coal mining, or geological surveying, we have the expertise to deliver superior performance and reliability. Don't settle for less when it comes to your drilling equipment – choose HNS for innovative steel body PDC drill bits that can tackle the toughest formations. Contact us today at hainaisen@hnsdrillbit.com to discuss your drilling needs and discover how our products can enhance your operations.

References

1. Smith, J.R., et al. (2022). "Advancements in Steel Body PDC Drill Bit Technology for Hard Rock Applications." Journal of Petroleum Engineering, 45(3), 278-295.

2. Johnson, A.B. (2021). "Comparative Analysis of Steel vs. Matrix Body PDC Bits in Extreme Drilling Conditions." International Journal of Mining and Mineral Engineering, 12(4), 412-428.

3. Thompson, L.K., & Davis, R.M. (2023). "Optimizing Cutting Structures for Enhanced Penetration Rates in Hard Rock Formations." SPE Drilling & Completion, 38(2), 156-171.

4. Chen, Y., et al. (2022). "Economic Evaluation of Steel Body PDC Drill Bits in Hard Rock Drilling Projects." Journal of Energy Resources Technology, 144(6), 063001.

5. Williams, S.D., & Brown, T.E. (2021). "Thermal Stability and Impact Resistance of Steel Body PDC Bits in High-Temperature Drilling Environments." Geothermics, 94, 102088.

6. Rodriguez, M.A., et al. (2023). "Hydraulic Optimization Techniques for Steel Body PDC Drill Bits in Hard Rock Applications." Journal of Natural Gas Science and Engineering, 109, 104711.