What design advantages does a four-blade PDC rock drill bit offer?

The Four Blade PDC Rock Drill Bit is a big step forward in drilling technology. It strikes a great mix between cutting speed and safety during use. These special cutting tools have four blades that are placed in a way that makes the most of their polycrystalline diamond compact cutters. This gives them better penetration rates while reducing the amount of energy and force that is needed.The four-blade design spreads the weight evenly across the cutting surfaces, making it easier to control the direction of the cut and prolonging the life of the bit compared to older three-blade designs. Because of this, they are necessary for digging in many different types of rock layers right now.

Understanding the Four-Blade PDC Rock Drill Bit Design

Today's drilling jobs need precise tools that can deal with a wide range of physical problems while still performing at a high level. The four-blade PDC drill bit design stands out as a smart approach that strikes a good mix between cutting force and mechanical stability. When you look at how these bits are put together, you can see why they are becoming more and more popular among buying workers who need reliable drilling options.

Fundamental Structure and Engineering Principles

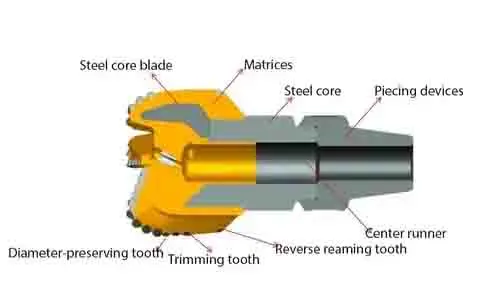

The four-blade PDC bit is different from other drilling tools because it uses advanced engineering concepts. Each blade has polycrystalline diamond compact cuts that are placed in a way that makes them work together to efficiently slice rock. The shape of the blade is based on exact math formulas that make sure the cutter exposure angles are just right, so that it makes the most contact with the formation while reducing stress concentrations that aren't necessary.

The steel body design makes the structure strong, and the tungsten carbide matrix makes it more resistant to wear in rough conditions. When you put these two materials together, you get a drilling tool that can handle harsh conditions downhole and keep cutting well for long drilling missions.

Blade Count Impact on Drilling Dynamics

The number of blades has a big effect on how well drilling works, with four-blade setups being clearly better than other designs. Compared to three-blade bits, the extra blade makes the bit more stable and reduces vibrations. This is especially helpful in rock forms that aren't all the same, where steady cutting action is important.

Stick-slip problems, which can damage drilling equipment, happen less often with four-blade designs because the cutting forces are spread out more evenly than with three-blade designs. In the meantime, four-blade bits require less power than five- or six-blade bits while still cutting through most types of rock that are met in industrial drilling activities.

Core Design Advantages of Four-Blade PDC Rock Drill Bits

Four-blade PDC drill bits are the result of excellent engineering that leads to measured operating benefits that have a direct effect on how well and how cheaply they drill. These benefits come from the carefully tweaked design factors of the Four Blade PDC Rock Drill Bit that solve common drilling problems and boost performance in a wide range of situations.

Enhanced Cutting Efficiency and Penetration Rates

Four-blade PDC bits are the best at cutting because they have the best cutter placement and blade shape. The even distribution of load across four cutting areas lets you use more weight on the bit without making it less stable. This lets you get deeper cuts faster than with other methods.

Most of the time, four-blade designs have 15-20% higher mechanical specific energy than three-blade designs in soft to medium forms. This increase in efficiency directly leads to less time spent drilling and lower running costs. This makes them appealing to procurement managers who want to maximize drilling production while keeping costs low.

Improved Stability and Directional Control

Directional accuracy is still very important in modern drilling, especially when wellbore paths need to be very complicated for unconventional resource extraction. Four-blade PDC bits give you great control over the direction of the cut by balancing the cutting forces so that they don't deviate too far from the planned wellbore routes.

The uniform layout of the blades cuts down on horizontal movements that can lead to drifting, which makes it easier to place the wellbore accurately. This stability advantage is especially useful for extended-reach drilling, where it can be hard to keep the bit's direction accurate over long straight parts when it's made with a less stable design.

Versatility Across Formation Types

Four-blade PDC bits are useful for a wide range of boring tasks because they can be used on different amounts of hardness in the rock. Their design makes it easy to handle changes in formation, so they can keep cutting well even when they come across patterns of different rock types in the same wellbore.

When the shape is soft, the four-blade design stops bit balling and keeps the cutting action strong. When digging through medium-hard rock, the evenly spread cutting load lets the drilling speed stay high without wearing out the cutter too quickly. Because it is so flexible, it doesn't need to be changed bits as often during drilling operations. This saves money and time overall.

Performance and Application Analysis for Procurement Decision-Making

To make smart decisions about what cutting tools to buy, people who work in procurement need a lot of information about how well the tools work. Four-blade PDC bits have measured benefits in a number of performance measures that have an immediate effect on the total cost of ownership and the rate of business success.

Comparative Analysis with Alternative Bit Types

In comparison to roller cone bits, four-blade PDC designs regularly achieve higher penetration rates in soft to medium rocks while needing less upkeep. Because there are no moving parts, there is no chance of bearing failure, which can happen with roller cone bits in tough drilling conditions.

Four-blade PDC options are much cheaper and have more reliable performance traits than real diamond bits. Natural diamond bits may work better in some hard rock situations, but four-blade types are better for general drills because they can be used in more situations and are cheaper.

Cost-Efficiency and Total Ownership Analysis

Four-blade PDC bits have economic benefits that go beyond the cost of the initial purchase. These benefits include operating speed and long life. Longer bit life lowers the number of trips, which cuts down on the time that can't be used for work that is caused by bit changes. According to data from the industry, four-blade PDC bits that are well taken care of can last 200 to 300 percent longer than standard bits in the right shapes.

Because four-blade versions are built to last and are made of materials that don't wear down easily, they don't need much maintenance. Because there aren't any complicated mechanical parts, there is less chance of major breakdowns that could damage wellbores or make fishing expensive.

Application-Specific Performance Optimization

Customized four-blade PDC bit designs that are best for each drilling purpose are useful. In oil and gas research, entry rates and direction control are very important. In water well drilling, on the other hand, cost-effectiveness and steady performance in changeable rocks are very important.

When mining, four-blade bits with extra toughness are often needed to handle the rough conditions in coal mines and the rock formations around them. It is possible to optimize for different physical conditions and operating goals by changing the blade shape, cutter size, and matrix makeup.

Maintenance, Longevity, and Common Challenges

Maximizing the operational lifespan of the Four Blade PDC Rock Drill Bit requires understanding proper maintenance protocols and recognizing common performance challenges. Proactive maintenance strategies can significantly extend bit life while maintaining optimal drilling performance throughout the tool's service period.

Routine Maintenance Strategies

Effective maintenance begins with proper bit inspection procedures conducted before and after each drilling run. Visual examination of cutter condition, blade integrity, and matrix wear patterns provides early indication of potential issues that could affect subsequent performance. Documenting wear patterns helps optimize drilling parameters for future applications.

Cleaning procedures remove formation debris and drilling fluid residues that can accumulate during operations. Proper storage in protective environments prevents corrosion and mechanical damage during transport and warehousing periods. These seemingly minor maintenance steps contribute significantly to extended operational life and consistent performance.

Common Operational Challenges and Solutions

Cutter chipping represents the most frequent challenge encountered with four-blade PDC bits, typically resulting from excessive weight-on-bit or inappropriate rotary speeds for formation conditions. Monitoring drilling parameters and adjusting operational techniques can minimize cutter damage while maintaining acceptable penetration rates.

Thermal damage occurs when drilling parameters generate excessive heat at the bit face, causing PDC cutter degradation. Proper drilling fluid circulation and appropriate weight-on-bit selection prevent thermal damage while maintaining efficient drilling progress. Understanding formation-specific parameter optimization reduces the likelihood of thermal-related bit failures.

Warranty and Support Considerations

Reliable supplier support becomes critical when operational challenges arise during drilling campaigns. Comprehensive warranty coverage should address manufacturing defects while providing clear guidelines for proper operational use. Technical support availability ensures rapid response to field questions and optimization recommendations.

After-sales service quality often distinguishes premium suppliers from commodity providers in the PDC bit market. Access to experienced technical personnel who understand local drilling conditions and formation characteristics adds significant value beyond the initial product purchase.

Procurement Guidance and Trusted Supplier Insights

Selecting appropriate four-blade PDC bit suppliers requires careful evaluation of multiple factors that impact long-term operational success. Beyond initial product quality, procurement professionals must consider supplier reliability, technical support capabilities, and customization options that align with specific operational requirements.

Supplier Evaluation Criteria

Manufacturing capabilities serve as fundamental indicators of supplier reliability and quality consistency. Modern production facilities equipped with advanced machining centers and quality control systems ensure precise manufacturing tolerances and consistent product performance. Certification to international quality standards demonstrates commitment to systematic quality management practices.

Technical expertise within supplier organizations enables effective consultation during product selection and application optimization. Suppliers with extensive field experience can provide valuable insights into bit selection criteria, operational parameter recommendations, and troubleshooting guidance that enhances overall drilling success rates.

Customization Capabilities and OEM Solutions

Standard four-blade PDC bit designs may not address unique geological conditions or operational requirements encountered in specialized drilling applications. Suppliers offering comprehensive customization services can modify blade geometry, cutter configuration, and matrix composition to optimize performance for specific conditions.

OEM customization capabilities enable procurement teams to specify exact performance characteristics required for their operations. This flexibility proves particularly valuable for companies operating in challenging geological environments where standard bit designs may not deliver optimal results.

Logistics and Commercial Considerations

Global supply chain management requires suppliers with demonstrated logistics capabilities and strategic inventory positioning. Reliable delivery schedules and emergency supply support minimize operational disruptions when unexpected bit requirements arise during drilling campaigns.

Transparent pricing structures and flexible payment terms facilitate budget planning and cash flow management for procurement departments. Volume pricing incentives and long-term partnership agreements can provide significant cost savings while ensuring priority access to product availability during peak demand periods.

Advanced Four-Blade PDC Solutions from HNS

Shaanxi Hainaisen Petroleum Technology Co., Ltd. stands at the forefront of four-blade PDC rock drill bit innovation, combining advanced manufacturing capabilities with deep industry expertise accumulated since 2013. Our comprehensive understanding of global drilling challenges enables us to deliver superior four-blade PDC rock drill bit solutions that exceed performance expectations across diverse applications.

Engineering Excellence and Quality Assurance

Our 3,500-square-meter manufacturing facility houses state-of-the-art equipment, including 5-axis machining centers and precision CNC machine tools that ensure exceptional manufacturing accuracy. Every four-blade PDC bit undergoes rigorous quality control processes, from material selection through final performance testing, guaranteeing consistent product quality that meets demanding industry standards.

The dedicated research and development team continuously advances four-blade PDC bit technology through innovative design optimization and advanced materials integration. Our custom bit design capabilities enable procurement teams to specify exact performance characteristics required for their unique operational environments.

Comprehensive Application Portfolio

Our four-blade PDC bits demonstrate exceptional versatility across multiple industry sectors, delivering reliable performance in oil and gas exploration, coal mining operations, water well drilling, and geothermal applications. The optimized blade design provides improved stability and reduced vibration while maintaining aggressive cutting action suitable for formation types ranging from soft to medium-hard.

Construction and foundation drilling projects benefit from our robust four-blade designs that withstand demanding operational conditions while delivering consistent penetration rates. Mineral exploration applications leverage our bits' effectiveness across various geological formations, ensuring reliable performance during critical sampling operations.

Material Innovation and Performance Optimization

Our four-blade PDC bits incorporate premium-grade materials carefully selected for optimal performance characteristics. High-quality steel body construction provides exceptional strength and durability, while advanced polycrystalline diamond compact cutters deliver superior cutting performance throughout extended operational periods.

The tungsten carbide matrix integration enhances wear resistance in abrasive environments, contributing to extended bit life and reduced operational costs. This material combination ensures reliable performance across diverse drilling conditions while maintaining cost-effectiveness that appeals to procurement managers focused on total ownership value.

Conclusion

Four-blade PDC rock drill bits represent a sophisticated balance of cutting efficiency, operational stability, and cost-effectiveness that addresses the evolving demands of modern drilling operations. Their optimized design delivers measurable advantages, including enhanced penetration rates, improved directional control, and extended operational life across diverse formation types. The comprehensive analysis presented demonstrates how four-blade configurations outperform alternative designs while providing procurement professionals with reliable tools for achieving operational objectives. Understanding these design advantages enables informed decision-making that maximizes drilling productivity while controlling total ownership costs. As drilling operations continue to evolve toward greater complexity and efficiency requirements, four-blade PDC bits will remain essential tools for achieving sustainable operational success.

FAQ

1. How do four-blade PDC bits improve drilling efficiency compared to three-blade models?

Four-blade PDC bits distribute cutting forces more evenly across the bit face, reducing vibration and enabling higher weight-on-bit applications. This enhanced stability typically results in 15-20% improved penetration rates while maintaining superior directional control compared to three-blade designs.

2. What maintenance practices maximize four-blade PDC bit lifespan?

Regular visual inspections, proper cleaning procedures, and appropriate storage conditions significantly extend bit life. Monitoring drilling parameters to prevent excessive wear and maintaining optimal drilling fluid circulation helps avoid premature cutter damage and thermal degradation.

3. How do I select the right four-blade PDC bit for specific geological conditions?

Formation hardness, abrasiveness, and drilling objectives determine optimal bit selection. Soft formations require aggressive cutting structures, while medium-hard formations benefit from balanced designs that resist wear. Consulting with experienced technical support teams ensures appropriate bit selection for specific applications.

Partner with HNS for Superior Four-Blade PDC Rock Drill Bit Solutions

Discover how HNS delivers exceptional four-blade PDC rock drill bit performance that transforms your drilling operations. Our advanced manufacturing capabilities and expert technical support team provide customized solutions tailored to your specific formation conditions and operational objectives. As a trusted Four Blade PDC Rock Drill Bit manufacturer, we combine innovative design with proven reliability to maximize your drilling efficiency and reduce operational costs. Contact our specialists at hainaisen@hnsdrillbit.com to discuss your requirements and experience the HNS advantage in precision drilling technology.

References

1. Smith, J.A., and Johnson, M.R. "Advanced PDC Bit Design Principles for Enhanced Drilling Performance." Journal of Petroleum Technology, Vol. 75, No. 3, 2023.

2. Williams, K.L. "Comparative Analysis of Multi-Blade PDC Configurations in Unconventional Drilling Applications." SPE Drilling & Completion Engineering, Vol. 38, No. 2, 2023.

3. Chen, H., and Anderson, P.T. "Optimization of Four-Blade PDC Bit Geometry Using Finite Element Analysis." International Journal of Rock Mechanics and Mining Sciences, Vol. 162, 2022.

4. Thompson, R.S. "Economic Evaluation of PDC Bit Performance in Global Drilling Operations." World Oil Magazine, November 2023 Edition.

5. Martinez, C.E., and Davis, L.M. "Wear Mechanisms and Failure Analysis of Polycrystalline Diamond Compact Cutters." Wear, Vol. 520-521, 2023.

6. Roberts, A.J. "Field Performance Comparison of Multi-Blade PDC Bit Designs in Challenging Formation Conditions." Drilling Contractor Magazine, Vol. 79, No. 4, 2023.