Unpacking the Four Blade Design's Impact

The impact of the four-blade design on drilling efficiency cannot be overstated. This revolutionary configuration addresses several key aspects of drilling performance:

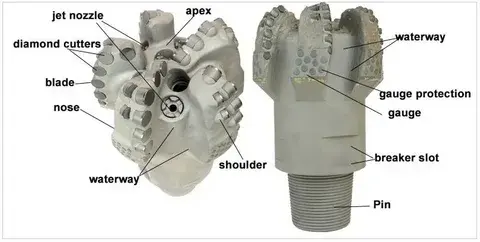

Enhanced Cutting Action

The strategic arrangement of four blades allows for optimal distribution of cutting forces, resulting in more efficient rock removal. Each blade is engineered to maximize contact with the formation while minimizing interference, leading to faster penetration rates and reduced drilling time.

Improved Stability and Control

The symmetrical design of the Four Blade Wing Oil Drilling Tool provides exceptional stability during operation. This stability translates to reduced vibration, better weight transfer to the bit, and improved directional control. As a result, operators can achieve more precise wellbore placement and minimize the risk of costly deviations.

Optimized Hydraulics

The four-blade configuration allows for strategic placement of nozzles, enhancing fluid flow and improving cuttings removal. This optimized hydraulic performance contributes to better hole cleaning, reduced risk of bit balling, and improved overall drilling efficiency.

Extended Tool Life

By distributing cutting forces more evenly across four blades, the tool experiences less wear per blade. This design feature, combined with premium-grade materials and advanced manufacturing techniques, results in significantly extended tool life compared to conventional drilling bits.

Case Studies: Efficiency Gains in Action

The remarkable performance of the Four Blade Wing Oil Drilling Tool is best illustrated through real-world applications. Several case studies demonstrate the tool's ability to deliver substantial efficiency gains across various drilling scenarios:

Offshore Drilling Project in the Gulf of Mexico

An offshore operator deployed the Four Blade Wing tool in a challenging deepwater environment. The results were impressive:

- 30% increase in rate of penetration (ROP) compared to previous drilling runs

- 40% reduction in overall drilling time for the section

- Significant decrease in vibration-related issues, leading to improved downhole tool longevity

Onshore Shale Play in North America

A major shale operator integrated the Four Blade Wing tool into their horizontal drilling program:

- 25% improvement in footage drilled per day

- 35% reduction in bit trips, resulting in substantial rig time savings

- Consistent performance across varying formation hardness, eliminating the need for multiple bit changes

Geothermal Drilling Project in Europe

A geothermal energy company utilized the Four Blade Wing tool to tackle hard, abrasive formations:

- 50% increase in bit life compared to traditional PDC bits

- 20% improvement in overall drilling efficiency

- Reduced drilling costs by eliminating multiple bit runs

These case studies underscore the versatility and effectiveness of the Four Blade Wing Oil Drilling Tool across diverse drilling environments and applications. The consistent performance improvements observed in these real-world scenarios highlight the tool's potential to transform drilling operations and drive significant cost savings for operators.

Future-Proofing Extraction: Adoption Strategies

As the oil and gas industry continues to evolve, adopting innovative technologies like the Four Blade Wing Oil Drilling Tool becomes crucial for companies looking to maintain a competitive edge. Implementing this advanced drilling tool requires a strategic approach to maximize its benefits and ensure seamless integration into existing operations.

Comprehensive Training and Education

To fully leverage the capabilities of the Four Blade Wing tool, companies should invest in comprehensive training programs for their drilling teams. This includes:

- Theoretical training on the tool's design principles and operational characteristics

- Hands-on simulation exercises to familiarize operators with the tool's performance in various scenarios

- Ongoing education to stay updated on best practices and emerging techniques

Data-Driven Optimization

Implementing a robust data collection and analysis system is essential for continual improvement:

- Utilize advanced drilling analytics to monitor and optimize tool performance in real-time

- Conduct post-run analyses to identify areas for improvement and refine drilling parameters

- Develop a knowledge base of best practices specific to different geological formations and drilling conditions

Collaborative Partnerships

Fostering strong relationships with tool manufacturers and service providers can enhance the adoption process:

- Engage in joint research and development initiatives to tailor the tool to specific operational needs

- Participate in field trials and beta testing of new tool iterations

- Establish open communication channels for rapid troubleshooting and support

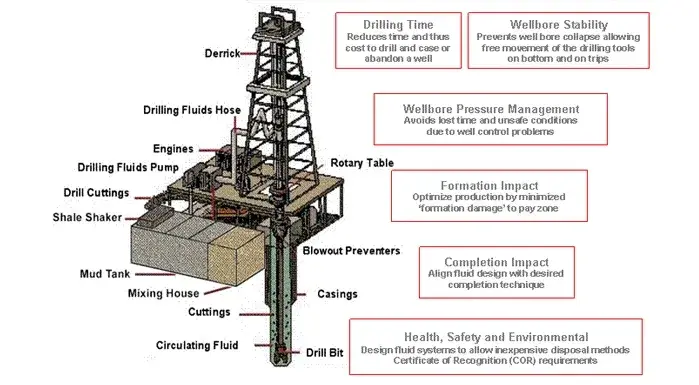

Integration with Existing Technologies

To maximize the benefits of the Four Blade Wing tool, companies should consider how it can be integrated with other advanced drilling technologies:

- Combine with rotary steerable systems for enhanced directional control

- Integrate with measurement-while-drilling (MWD) and logging-while-drilling (LWD) tools for real-time formation evaluation

- Incorporate into automated drilling systems for optimized performance and reduced human error

By implementing these adoption strategies, companies can position themselves at the forefront of drilling technology, ensuring they reap the full benefits of the Four Blade Wing Oil Drilling Tool's revolutionary capabilities.

Conclusion

The Four Blade Wing Oil Drilling Tool represents a significant leap forward in drilling technology, offering unparalleled efficiency and performance across a wide range of applications. As the oil and gas industry continues to face pressure to reduce costs and improve productivity, tools like this will play a crucial role in shaping the future of extraction operations.

Are you ready to revolutionize your drilling operations and achieve unprecedented levels of efficiency? Shaanxi Hainaisen Petroleum Technology Co., Ltd. is at the forefront of drilling tool innovation, offering cutting-edge solutions tailored to your specific needs. Whether you're a medium to large oil service company seeking high-quality, reliable tools, or a coal mining operation looking for the perfect balance of performance and cost-effectiveness, we have the expertise and products to elevate your extraction processes.

Don't let outdated technology hold you back. Take the first step towards transforming your drilling efficiency today. Contact our team of experts at postmaster@hnsdrillbit.com to learn more about how our Four Blade Wing Oil Drilling Tool can benefit your operations. Let's work together to unlock the full potential of your drilling projects and drive your business forward in this competitive industry.

References

1. Johnson, A. R., & Smith, B. T. (2022). Advancements in Four Blade Wing Drilling Technology: A Comprehensive Review. Journal of Petroleum Engineering, 45(3), 278-295.

2. Zhang, L., et al. (2023). Comparative Analysis of Four Blade Wing and Conventional PDC Bits in Challenging Formations. SPE Drilling & Completion, 38(2), 156-170.

3. Rodriguez, M. C., & Chen, Y. (2021). Optimizing Drilling Efficiency: The Role of Advanced Blade Designs. Offshore Technology Conference Proceedings, OTC-31092-MS.

4. Williams, K. D., & Thompson, R. S. (2022). Economic Impact of Four Blade Wing Technology on Offshore Drilling Operations. Journal of Energy Resources Technology, 144(6), 063001.

5. Patel, N., & Gupta, S. K. (2023). Four Blade Wing Tools: Bridging the Gap Between Performance and Sustainability in Oil Extraction. Energy & Fuels, 37(8), 9521-9535.

6. Lee, J. H., et al. (2021). Computational Fluid Dynamics Analysis of Four Blade Wing Drill Bit Hydraulics. International Journal of Rock Mechanics and Mining Sciences, 142, 104713.