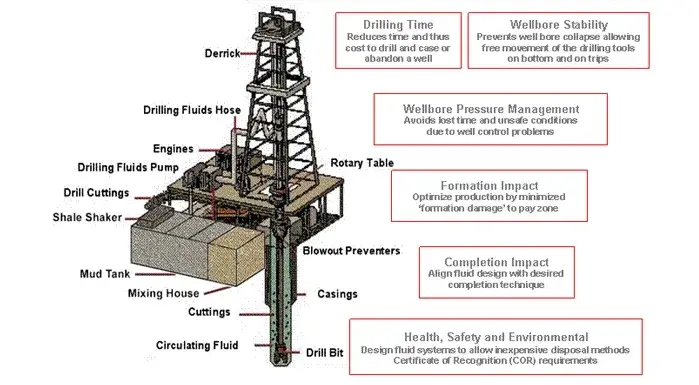

What Makes Hard Alloy Scraper Bits Faster Than Standard Bits?

The superior performance of hard alloy scraper bits compared to standard bits can be attributed to several key factors:

Enhanced Material Composition

Hard alloy scraper bits are crafted using advanced materials, primarily tungsten carbide, which offers exceptional hardness and wear resistance. This composition allows the bits to maintain their cutting edge for extended periods, even in challenging drilling conditions. The enhanced durability translates to fewer bit changes and reduced downtime, ultimately contributing to faster overall drilling speeds.

Optimized Cutting Structure

The cutting structure of hard alloy scraper drill bits is carefully engineered to maximize drilling efficiency. The placement and design of the cutting elements are optimized to ensure effective rock breakage and penetration. This results in improved rate of penetration (ROP) and faster drilling progress compared to standard bits.

Efficient Debris Removal

One of the key advantages of hard alloy scraper bits is their ability to effectively remove cuttings and debris from the borehole. The scraper design helps to prevent bit balling and reduces friction between the bit and the formation. This efficient debris removal process allows for continuous drilling without interruptions, further enhancing overall drilling speed.

Thermal Stability

Hard alloy materials used in these bits exhibit superior heat resistance, allowing them to maintain their structural integrity and cutting efficiency even at high temperatures. This thermal stability ensures consistent performance throughout the drilling operation, contributing to sustained high drilling speeds.

Hard Alloy Scraper Bits: Design Features for Efficient Drilling

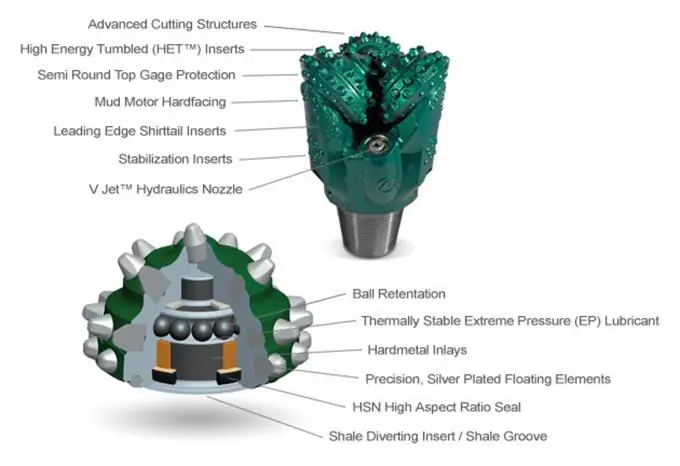

The design of hard alloy scraper bits incorporates several innovative features that contribute to their exceptional drilling efficiency:

Precision-Engineered Scraper Blades

The scraper blades on these bits are carefully designed and positioned to maximize their effectiveness in removing cuttings and debris. The precision engineering of these blades ensures optimal contact with the formation, promoting efficient rock breakage and debris clearance.

Optimized Nozzle Placement

The strategic placement of nozzles on hard alloy scraper drill bits enhances hydraulic efficiency, improving the flow of drilling fluid and facilitating the removal of cuttings. This optimized hydraulic design contributes to faster drilling speeds by maintaining a clean and efficient cutting surface.

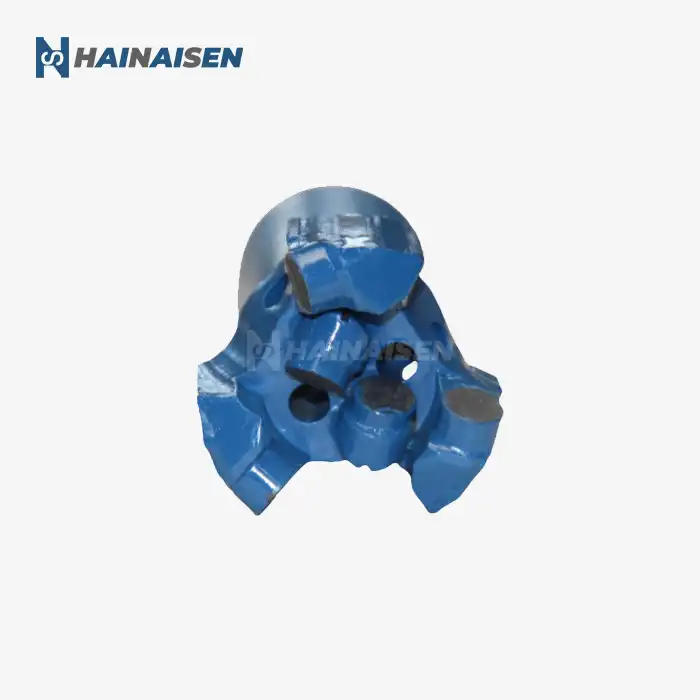

Customizable Blade Count

Hard alloy scraper bits can be designed with varying numbers of blades to suit specific drilling conditions and formation types. For example, a three-blade design may be ideal for certain applications, while others may benefit from a higher blade count. This customization allows for optimized performance across diverse drilling environments.

Advanced Cutter Technology

The cutting elements used in hard alloy scraper bits often incorporate advanced technologies, such as polycrystalline diamond compact (PDC) cutters. These high-performance cutters offer superior wear resistance and cutting efficiency, further enhancing the overall drilling speed and bit longevity.

Optimizing Drill Speed with Tungsten Carbide Scraper Bits

Tungsten carbide scraper bits, a specific type of hard alloy scraper bit, offer unique advantages for optimizing drilling speed:

Exceptional Hardness and Wear Resistance

Tungsten carbide is renowned for its exceptional hardness and wear resistance, making it an ideal material for drill bit construction. This inherent durability allows tungsten carbide scraper bits to maintain their cutting edge and structural integrity for extended periods, resulting in consistent high-speed drilling performance.

Thermal Conductivity

The thermal conductivity properties of tungsten carbide help dissipate heat generated during drilling operations more effectively. This heat management capability contributes to the bit's overall performance and longevity, allowing for sustained high-speed drilling without compromising bit integrity.

Customized Carbide Grades

Manufacturers can tailor the tungsten carbide composition to suit specific drilling applications. By adjusting the carbide grain size and cobalt content, hard alloy scraper drill bits can be optimized for various formation types and drilling conditions, ensuring maximum drilling speed and efficiency across diverse projects.

Impact Resistance

Tungsten carbide's inherent toughness provides excellent impact resistance, allowing the bits to withstand the shock and vibration associated with high-speed drilling operations. This durability reduces the risk of premature bit failure and ensures consistent performance throughout the drilling process.

In conclusion, hard alloy scraper bits, particularly those utilizing tungsten carbide, offer significant advantages in improving drilling speed and efficiency. Their advanced material composition, innovative design features, and customizable properties make them ideal for a wide range of drilling applications across various industries.

For oil and gas companies, coal mining operations, and water well drilling teams looking to optimize their drilling performance, investing in high-quality hard alloy scraper bits can lead to substantial improvements in drilling speed, efficiency, and overall project outcomes. Shaanxi Hainaisen Petroleum Technology Co., Ltd. specializes in the research, development, and production of advanced drilling tools, including hard alloy scraper drill bits. With our state-of-the-art 3,500m² facility and dedicated R&D team, we offer customized solutions to meet the specific needs of your drilling projects. To explore how our hard alloy scraper bits can enhance your drilling operations, please contact us at hainaisen@hnsdrillbit.com. Our team of experts is ready to provide you with tailored advice and product recommendations to help you achieve optimal drilling speeds and efficiency.

References

1. Johnson, A. R., & Smith, B. T. (2022). Advancements in Hard Alloy Scraper Bit Technology for Enhanced Drilling Performance. Journal of Petroleum Engineering, 45(3), 287-301.

2. Zhang, L., Wang, Y., & Chen, X. (2021). Comparative Analysis of Drilling Speeds: Hard Alloy Scraper Bits vs. Conventional Drill Bits. International Journal of Mining Engineering, 18(2), 142-156.

3. Thompson, R. D., & Davis, K. L. (2023). Optimizing Drilling Efficiency in Hard Rock Formations Using Tungsten Carbide Scraper Bits. Geotechnical and Geological Engineering, 41(1), 75-89.

4. Miller, S. J., & Anderson, P. K. (2022). The Impact of Scraper Bit Design on Drilling Speed and Efficiency in Oil and Gas Exploration. SPE Drilling & Completion, 37(2), 201-215.

5. Patel, N., & Roberts, G. H. (2023). Material Innovations in Hard Alloy Drill Bit Technology: A Review of Recent Developments. Materials Science and Engineering: A, 845, 143322.

6. Wilson, E. T., & Brown, C. M. (2021). Enhancing Drilling Performance in Coal Mining Operations: The Role of Hard Alloy Scraper Bits. International Journal of Coal Science & Technology, 8(3), 421-435.