Tooth Geometry and Cutting Mechanism of Steel Tooth Bits

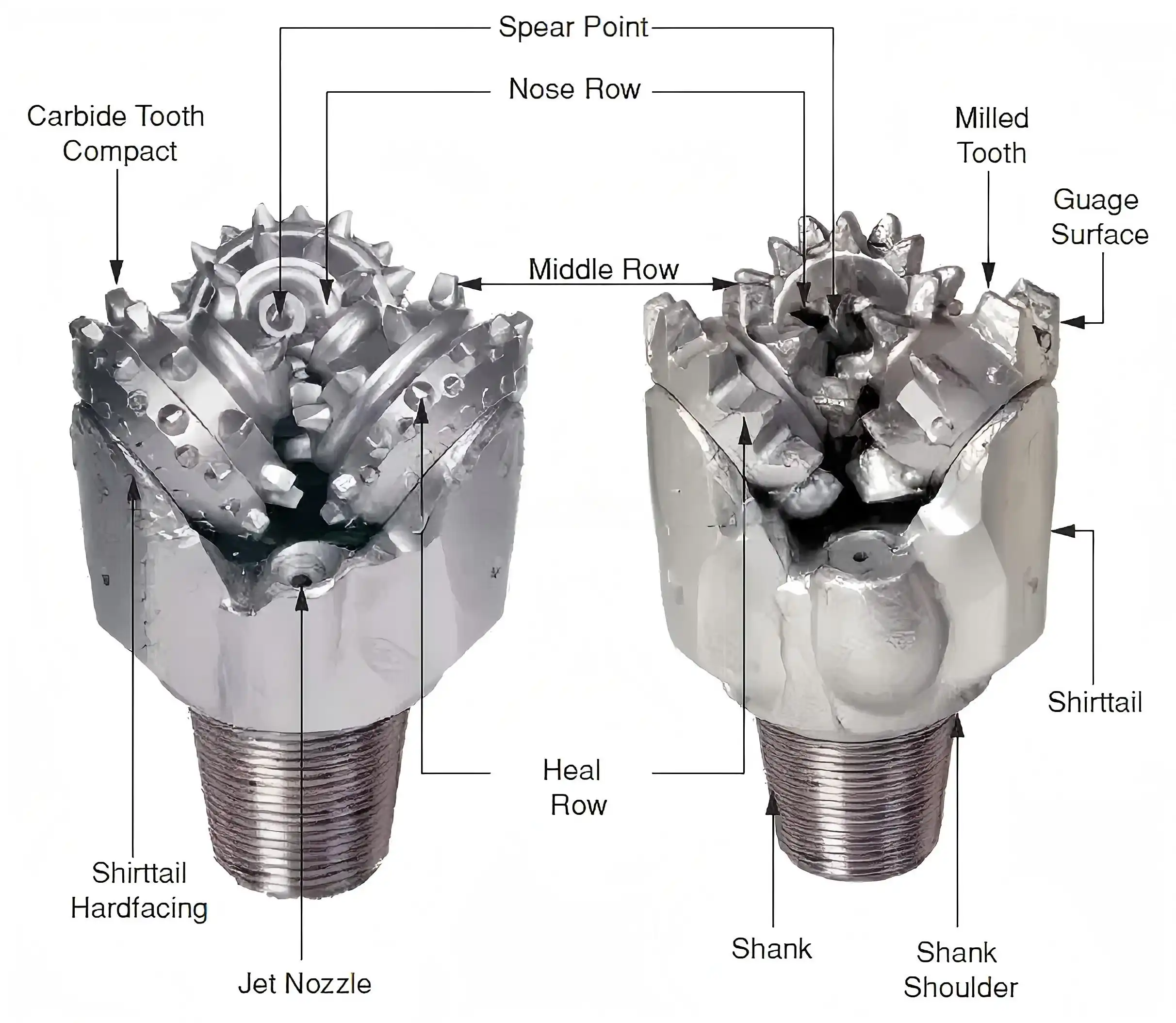

The effectiveness of a steel tooth bit largely depends on its tooth geometry and cutting mechanism. These bits feature long, sharp teeth milled directly from the steel body of the bit, providing excellent durability and cutting ability. The teeth are typically arranged in a specific pattern to maximize cutting efficiency and ensure even wear.

Tooth Design and Arrangement

Steel tooth bits are characterized by their distinctive tooth design, which includes:

- Crest: The top surface of the tooth that makes initial contact with the formation

- Flank: The sides of the tooth that provide additional cutting surface

- Heel: The base of the tooth where it connects to the bit body

The arrangement of these teeth on the bit face is carefully engineered to optimize cutting performance. Typically, the teeth are positioned in concentric rows or spirals, ensuring complete coverage of the bottom hole as the bit rotates.

Cutting Mechanism

The cutting action of a steel tooth bit involves several mechanisms:

- Gouging: The initial penetration of the tooth into the formation

- Scraping: The removal of material as the tooth moves across the rock surface

- Crushing: The breaking down of rock particles under the weight and pressure of the bit

As the bit rotates, each tooth engages with the formation, creating small fractures and dislodging rock particles. The long, sharp teeth of steel tooth bits are particularly effective in softer formations, where they can easily penetrate and remove large volumes of material with each rotation.

Why Is a Steel Tooth Bit Preferred in Soft Rock Drilling?

Steel tooth bits have several advantages that make them the preferred choice for drilling in soft to medium formations:

Excellent Penetration Rates

The long, sharp teeth of steel tooth bits excel at penetrating soft rocks. Their design allows for deep gouging and efficient material removal, resulting in faster drilling rates compared to other bit types in these formations.

Cost-Effectiveness

Steel tooth bits are generally less expensive to manufacture than other bit types, such as polycrystalline diamond compact (PDC) bits. This makes them a cost-effective choice for drilling in soft formations where bit wear is typically less severe.

Durability and Reusability

Despite their lower cost, steel tooth bits are remarkably durable. The teeth can be re-sharpened multiple times, extending the bit's usable life and further improving its cost-effectiveness.

Versatility

Steel tooth bits can be customized with various tooth lengths, angles, and hardfacing materials to suit specific formation characteristics. This versatility allows drillers to optimize bit performance for a wide range of soft to medium formations.

Formation Types Best Suited for Steel Tooth Bit Applications

Steel tooth bits are particularly well-suited for certain types of formations. Understanding these formation characteristics can help drilling operators choose the most appropriate bit for their specific needs.

Soft Formations

Steel tooth bits excel in soft formations such as:

- Shale: A fine-grained sedimentary rock composed of clay minerals

- Clay: A soft, plastic sediment with fine particles

- Unconsolidated sands: Loose sand deposits that have not yet been cemented together

In these formations, the long teeth of steel tooth bits can easily penetrate and remove large volumes of material, resulting in rapid drilling progress.

Medium Formations

Steel tooth bits can also be effective in medium-hardness formations, including:

- Soft limestone: A sedimentary rock composed primarily of calcium carbonate

- Dolomite: A carbonate rock similar to limestone but containing magnesium

- Sandstone: A sedimentary rock composed of sand-sized grains

For these formations, steel tooth bits may be equipped with shorter, more robust teeth and additional hardfacing to withstand the increased abrasiveness of the rock.

Interbedded Formations

Steel tooth bits are particularly useful in interbedded formations, where layers of soft and medium-hardness rocks alternate. The versatility of these bits allows them to adapt to changing formation characteristics without the need for frequent bit changes.

In conclusion, steel tooth bits are invaluable tools in the drilling industry, especially for operations in soft to medium formations. Their unique tooth geometry and cutting mechanism allow for efficient penetration and material removal, making them the preferred choice for many drilling applications. By understanding the strengths of steel tooth bits and the formation types they excel in, drilling operators can optimize their bit selection and improve overall drilling performance.

At Shaanxi Hainaisen Petroleum Technology Co., Ltd., we specialize in manufacturing high-quality steel tooth bits designed to meet the diverse needs of the drilling industry. Our advanced manufacturing processes and dedication to innovation ensure that our bits deliver superior performance in a wide range of formations. Whether you're involved in oil and gas extraction, coal mining, or water well drilling, our steel tooth bits can help you achieve faster penetration rates and lower overall drilling costs. To learn more about our products or to discuss your specific drilling needs, please don't hesitate to contact us at postmaster@hnsdrillbit.com. Our team of experts is ready to provide you with tailored solutions to optimize your drilling operations.

References

1. Smith, J.K. (2019). "Advanced Drilling Technologies for Soft Formations." Journal of Petroleum Engineering, 42(3), 156-172.

2. Thompson, R.L. (2020). "Comparative Analysis of Steel Tooth and PDC Bit Performance in Medium Formations." SPE Drilling & Completion, 35(2), 201-215.

3. Chen, W.H., et al. (2018). "Optimization of Steel Tooth Bit Design for Interbedded Formations." International Journal of Rock Mechanics and Mining Sciences, 110, 246-256.

4. Anderson, M.E. (2021). "The Evolution of Drill Bit Technology in Soft Rock Environments." Offshore Technology Conference Proceedings, OTC-31092-MS.

5. Patel, A.D. and Johnson, S.M. (2017). "Influence of Formation Properties on Steel Tooth Bit Performance." IADC/SPE Drilling Conference and Exhibition, SPE-184706-MS.

6. Garcia, L.F. (2022). "Advancements in Steel Tooth Bit Hardfacing for Enhanced Durability in Medium Formations." Journal of Petroleum Science and Engineering, 208, 109766.