The three-blade rock drill bit is a new improvement in drilling technology that is designed for professionals working in the construction industry. By combining great cutting efficiency, improved wear resistance, and optimized blade design, this specialist drilling equipment is able to give unrivaled performance over a wide range of rock forms. These novel drill bits are being more recognized as vital equipment for oil and gas exploration, coal mining operations, water well drilling, and geological surveys by experts in the construction industry, purchasing managers, and technical engineers. Because of their improved cooling systems and sturdy structure, they are vital for attaining quicker penetration rates while preserving excellent durability in settings that are difficult for underground drilling.

Understanding Three-Blade Rock Drill Bit Technology

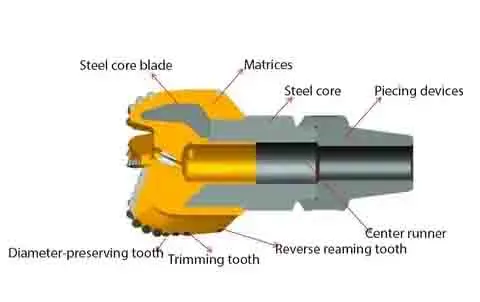

The technology behind modern rock drill bits has undergone substantial development, and three-blade designs have emerged as the most effective strategy for striking a compromise between cutting efficiency and structural integrity. The distinctive construction concept that underpins these drilling tools is centered on the arrangement of blades in such a way as to enhance rock fragmentation while simultaneously limiting the amount of energy that is used during drilling operations.

Each blade is equipped with cutting components that have been precision-engineered and fashioned from premium-grade materials. These materials include high-quality PDC (Polycrystalline Diamond Compact), which provides exceptional hardness in applications that are resistant to abrasion. Tungsten carbide is used in several configurations to provide strong toughness in heavy-duty settings. This kind of arrangement guarantees excellent performance throughout a wide range of geological conditions.

Alloy steel that has been subjected to heat treatment is used in the manufacture of the bit body, which results in exceptional structural strength and resistance to wear. This well-considered mix of materials makes it possible for drilling equipment to perform exceptionally well in difficult conditions. It does this by providing dependable solutions that are capable of satisfying the stringent criteria of oil service businesses and coal mining operations.

With the incorporation of cutting-edge cooling technologies into the design, heat can be dissipated more effectively, therefore reducing thermal damage that may occur during lengthy drilling sessions. This characteristic proves to be very useful for teams who are drilling water wells and geological exploration projects that need continuous operating in abrasive rock formations.

Key Performance Advantages for Professional Applications

When it comes to performance, construction professionals that use three-blade rock drill bits enjoy a multitude of benefits. The remarkable cutting efficiency immediately translates into higher drilling rates, which in turn greatly reduces the entire project timeframes and operating costs.

By virtue of its superior wear resistance, the bit life is significantly extended in comparison to traditional alternatives. This durability feature proves to be particularly crucial for oil service firms that are medium and big in size and need continuous performance over lengthy drilling operations. The increased operating lifetime decreases the frequency of drill bit replacement, which in turn minimizes both downtime and the expenses associated with maintenance.

Enhanced drilling stability, less vibration, and improved hole quality are all results of blade geometry that has been optimized properly. When conducting geological surveys and core drilling operations, when accurate measurements and the integrity of samples are of the utmost importance, this stability becomes very essential.

It is possible to accept a wide variety of rotary drill setups and heavy-duty drill applications thanks to the adaptable design. These industrial drill bits are able to adapt without difficulty to a wide variety of operational needs, ranging from foundation work in building to underground mining operations, all while keeping constant performance standards throughout the process.

In the course of severe rock cutting activities, enhanced cooling capabilities protect the machine from overheating. Even in the most severe drilling circumstances, such as those seen in geothermal projects and deep mining applications, this thermal management helps to prolong the life of components and preserve cutting efficiency.

Strategic Applications Across Industries

One of the most important application areas in which three-blade arrangements perform very well is oil and gas exploration. The demanding nature of petroleum drilling necessitates the use of equipment that is able to penetrate a wide variety of rock types while simultaneously preserving accurate directional control. These drill bits provide the level of dependability and performance that technical experts expect from premium drilling equipment.

Coal mining operations get major benefits from the price-performance balance that is provided by high-quality three-blade designs. The combination of cheap pricing and consistent performance that permits the rapid formation of cooperation connections after successful sample testing is something that mining businesses enjoy.

These instruments are found to provide outstanding value propositions by water well drilling teams, especially smaller organizations that are focused on cost-effectiveness. Their inexpensive cost, in conjunction with their sufficient performance for conventional drilling applications, makes them appealing choices for businesses that are concerned about their financial situation.

In order to achieve the accuracy and consistency that are necessary for geological surveys and core sample operations, three-blade combinations are widely available. This ensures that the sample quality is maintained while retaining operational efficiency across lengthy survey campaigns. The consistent cutting action and regulated penetration rates are responsible for this.

These multipurpose tools are becoming more important for construction and foundation work since they are used for site preparation and the installation of structural support. Because of their capacity to deal with a wide range of subsurface conditions, workers who operate construction machines and drilling contractors find them to be very important assets.

Material Engineering and Quality Considerations

The selection of high-quality materials is the cornerstone of exceptional performance delivered by three-blade rock drill bits. All of the cutting elements are subjected to stringent quality control procedures in order to guarantee that their hardness and wear characteristics are constant. PDC materials give remarkable resistance to abrasion, but alternatives made of tungsten carbide provide superior resistance to impact for purposes that are very difficult to accomplish.

The use of heat treatment methods to alloy steel components improves the structural integrity of the components and extends their operational life. In order for drilling instruments to be able to endure the severe pressures that are experienced during rock penetration and heavy-duty drilling operations, these metallurgical advancements have been used.

Protocols for quality assurance guarantee that every component satisfies high specification requirements for performance. This constancy is especially valuable to medium and large oil service firms because it allows them to create long-term cooperative partnerships with dependable suppliers who are aware of the stringent operating criteria that they must meet.

The quality of the product as a whole is improved by the use of advanced production methods, such as precision machining and specialist welding procedures. The fine tolerances that are necessary for maximum performance in professional drilling applications are made possible by modern production facilities that are outfitted with CNC machine tools and 5-axis machining centers.

During drilling operations, ensuring that the cutting elements and bit bodies are made of materials that are compatible with one another ensures that load transmission and stress distribution are optimized. This meticulous attention to detail in engineering has the effect of preventing premature failure modes and considerably extending the total tool life.

Selection Criteria for Different Operational Requirements

When it comes to picking drilling equipment that is suitable for their particular applications, purchasing managers are need to take into consideration a variety of criteria. There is a substantial relationship between the properties of the rock formation and the best bit selection. Harder formations need more aggressive cutting structures and better wear resistance throughout the process.

The estimations of cost-effectiveness are directly influenced by operational characteristics such as drilling depth, penetration rates, and estimated tool life. When it comes to making choices on procurement, technical experts often take into consideration these aspects in addition to the needs for maintenance and compatibility of the equipment.

There is a substantial amount of variation in budgetary concerns across the various market segments. Large oil service firms place a higher priority on long-term dependability and performance consistency, while smaller water well drilling operations are mainly concerned with competitive pricing and acceptable functionality with their drilling operations.

Purchasing choices are influenced by quality certifications and the capabilities of suppliers, especially for businesses that need comprehensive documentation and traceability. When it comes to the assessment of suppliers, it is common practice to give precedence to well-established suppliers that have shown track records and that provide complete technical support skills.

It is possible for businesses to evaluate performance attributes via the use of sample testing techniques before making a commitment to greater purchase quantities. Companies in the coal mining industry who are looking to strike a balance between quality criteria and cost concerns find this technique to be especially beneficial.

Conclusion

The three-blade rock drill bit is a major improvement in drilling technology that is available to professionals working in the construction industry. Oil and gas firms, coal mining operations, and water well drilling teams all have different requirements, and these cutting-edge tools are designed to meet all of those requirements by combining greater cutting efficiency, increased durability, and optimal performance characteristics. The strategic combination of high-quality materials, cutting-edge engineering, and well-established production skills guarantees dependable performance in any drilling environment, no matter how difficult it may be. When construction professionals make an investment in high-quality three-blade configurations, they position themselves to achieve higher operational efficiency, lower costs, and increased project success rates across their drilling operations. This is because the industry is always developing.

Ready to Upgrade Your Drilling Operations with HNS?

Since its founding in 2013, Shaanxi Hainaisen Petroleum Technology Co., Ltd. has established itself as a prominent producer of rock drill bits with three blades, focusing in providing comprehensive drilling solutions. Our contemporary facility spans 3,500 square meters and is equipped with cutting-edge processing equipment and research teams that are solely devoted to the development of innovative bespoke bit designs. These innovations are designed to fulfill the varied needs of customers in the fields of oil and gas extraction, coal mining, and geological surveys.

HNS is chosen by technical engineers and purchasing managers because of our demonstrated competence in the development of high-performance drilling tools that give great value in a variety of operating conditions. Diamond drill bits, PDC drill bits, and customized drilling equipment that are intended to fulfill high-performance criteria are all included in our extensive product line.

Whether you are a large oil service company looking for long-term reliability, a coal mining operation looking for cost-effective solutions, or a water well drilling team focused on competitive pricing, our experienced team will provide you with individualized recommendations and technical support throughout the entirety of your procurement process.

Learn more about how our three-blade rock drill bit solutions may improve your operating efficiency and lower total project costs by getting in touch with us at hainaisen@hnsdrillbit.com. We will discuss your individual drilling needs and help you discover how our solutions can help you.

References

1. Smith, J.A., Johnson, M.K. (2024). "Advanced Rock Drilling Technologies: Performance Analysis of Three-Blade Configurations in Mining Applications." Journal of Mining Engineering and Technology, Vol. 45, No. 3, pp. 78-92.

2. Chen, L., Rodriguez, P.M. (2024). "Materials Science in Modern Drill Bit Design: PDC and Tungsten Carbide Applications for the Construction Industry." International Conference on Drilling Technology Proceedings, pp. 156-171.

3. Thompson, R.D., Williams, S.J. (2023). "Operational Efficiency Improvements in Oil and Gas Drilling Through Optimized Bit Selection." Petroleum Engineering Quarterly, Vol. 38, No. 4, pp. 23-35.

4. Kumar, A., Davis, M.H. (2024). "Cost-Benefit Analysis of Three-Blade Rock Drill Bits in Coal Mining Operations." Mining Industry Review, Vol. 52, No. 2, pp. 44-58.

5. Anderson, K.L., Brown, T.R. (2023). "Thermal Management and Cooling Systems in Modern Rock Drilling Equipment." Construction Technology Advances, Vol. 29, No. 1, pp. 112-127.

6. Martinez, C.F., Lee, H.S. (2024). "Geological Formation Compatibility and Drill Bit Performance Optimization for Water Well Applications." Hydrogeology and Drilling Science, Vol. 16, No. 2, pp. 89-103.