Best High Performance 5 Cutter PDC Bit Applications

When looking for the best way to drill into difficult rocks, High Performance 5 Cutter PDC Bit technology is clearly the best option for mining, oil and gas projects, and geological surveys. These improved polycrystalline diamond compact bits cut very well, don't wear out as quickly, and have better penetration rates in a wide range of geological circumstances. Whether they are used on offshore drilling sites in the North Sea or to get gas from shale in Texas, these specialized drill bits always work better and cost less than other options. The five-cutter design makes the best use of weight distribution, reduces shaking, and improves boring performance in hard rock layers where other bits have trouble staying efficient.

Understanding the Critical Selection Process for Modern Drilling Operations

Equipment used in modern drills has to be able to handle harsh conditions underground and keep working properly. When working with difficult forms that need both toughness and cutting speed, picking the right PDC cutter design is very important.

Why Advanced Drill Bit Technology Matters

Today's digging sites bring problems that have never been seen before. Geological layers are getting more complicated, targets are getting deeper, and operators are facing smaller profit margins. When dealing with rough rocks or high temperatures, traditional drilling methods often don't work well. This fact makes it necessary to come up with new drill bit technology that can be used in a variety of situations.

The polycrystalline diamond compact technology is a big step forward in the ability to cut. These bits make tools that can keep working well in tough situations by combining fake diamond cuts with designed matrix bodies. The five-cutter design strikes the perfect mix between strong cutting action and bit steadiness, making it perfect for a wide range of boring tasks.

Essential Selection Criteria for Optimal Performance

There are many things that need to be carefully thought through when choosing the right drilling tools that have a direct effect on operating success. We looked at how well these methods cut, how long the bits lasted, how well they worked in different forms, how much they cost, and how well they had worked in the past.

When picking tools, metrics that measure how well they work are very important. The price and schedule of a project are directly linked to the rate of growth. Using bits that keep drilling speeds steady and last longer will save you a lot of money. It is faster to do things when you can work with different kinds of forms because you don't have to change bits as often.

Dependability is very important when you're thinking about digging sites that are far away or ocean platforms where machine problems cost a lot of money in lost time. You can be sure of your choice because of high standards for output, strict testing methods, and tools that have been used in the field before.

If you want to understand economics, you need to look at both the initial price and the total cost of ownership. When you buy high-end drilling tools, they may cost more at first, but they last longer and work better, which means that you often save money per foot and make more on the job.

Premium PDC Bit Solutions for Diverse Applications

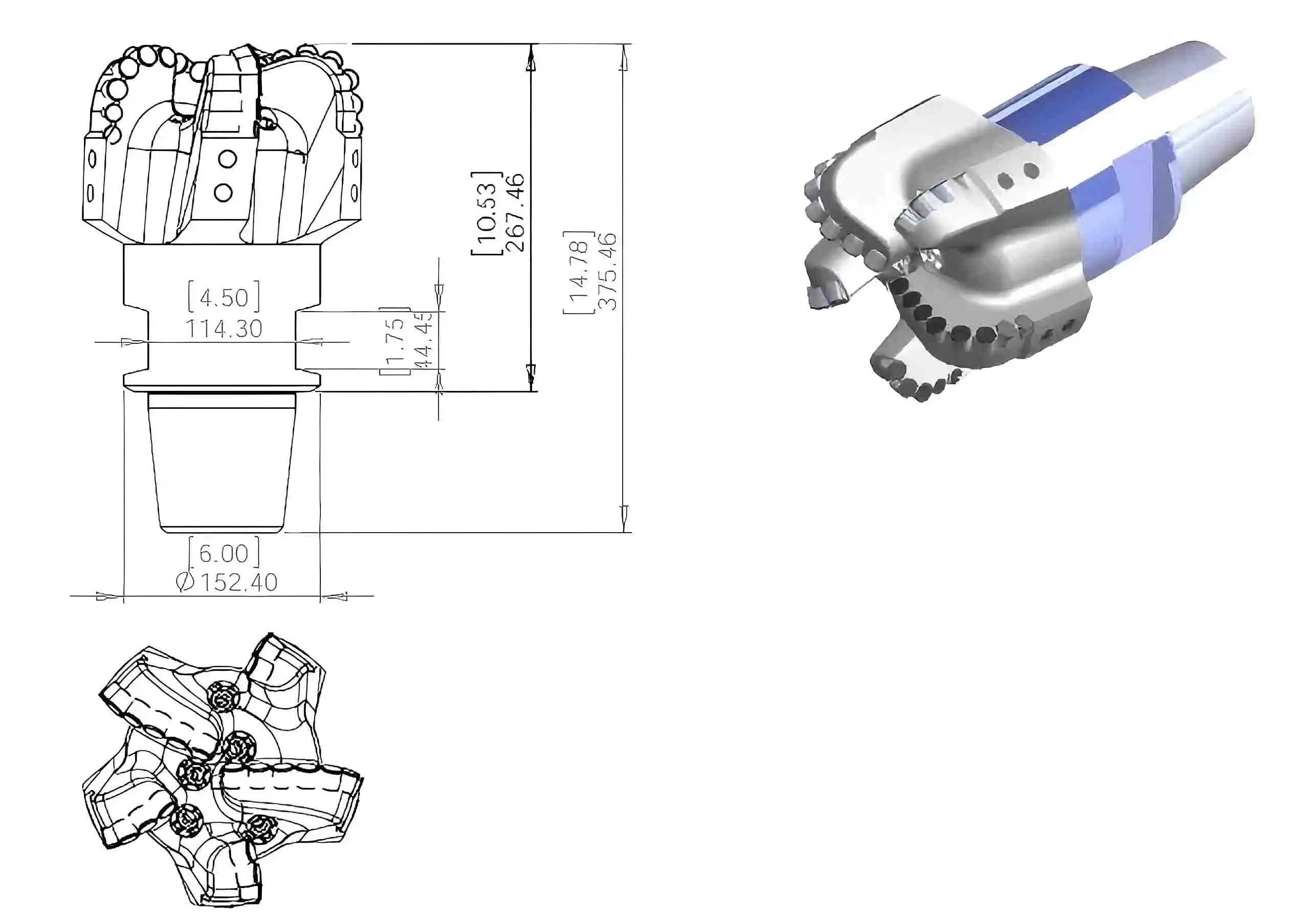

HNS Advanced Matrix PDC Series

The HNS Advanced Matrix PDC Series represents cutting-edge drill bit technology engineered for demanding drilling environments. These bits feature strategically positioned polycrystalline diamond compact cutters, including the High Performance 5 Cutter PDC Bit, that deliver exceptional rock drilling performance across multiple formation types.

Key Performance Features:

- Enhanced cutter placement optimizes load distribution and extends bit life

- Advanced hydraulic design promotes superior hole cleaning and cooling

- Reinforced matrix construction withstands high-impact drilling conditions

- Precision-engineered geometry reduces vibration and improves wellbore stability

- Temperature-resistant materials maintain performance in extreme environments.

The engineering team at Shaanxi Hainaisen Petroleum Technology has developed this series specifically for oil and gas drilling operations where consistent performance proves critical. Field testing across various geological conditions demonstrates significant improvements in penetration rates compared to conventional alternatives.

These bits excel in directional drilling applications where precise control becomes essential. The balanced cutting structure minimizes deviation tendencies while maintaining aggressive cutting action. Operators report average penetration rate improvements of 15-25% when transitioning from standard PDC bits to this advanced series.

Application Benefits:

- Reduced drilling time translates to lower operational costs.

- Extended bit life decreases equipment replacement frequency

- Improved hole quality reduces completion complications

- Enhanced durability minimizes downhole tool failures

- Customizable features accommodate specific formation requirements.

Heavy-Duty Mining PDC Configuration

Coal mining companies and hard rock mining operations require specialized drilling solutions that can withstand extreme wear conditions while maintaining cost-effective performance. The Heavy-Duty Mining PDC Configuration addresses these specific operational demands.

Specialized Design Elements:

- Reinforced cutter retention systems prevent premature cutter loss

- Abrasion-resistant matrix materials extend operational life in harsh conditions.

- Optimized cutting angles improve efficiency in consolidated formations

- Robust bit body construction handles high-torque applications

- Field-replaceable components reduce long-term operational costs.

This configuration proves particularly effective in coal bed methane drilling, where operators encounter varying formation hardness and abrasive materials. The tungsten carbide matrix provides exceptional wear resistance, while the strategic cutter placement maintains cutting efficiency throughout the bit's operational life.

Mining operations benefit from the economic advantages these bits provide. The extended operational life reduces equipment replacement costs, while improved drilling efficiency increases daily footage targets. Quality control measures ensure consistent performance across production batches, enabling reliable operational planning.

Operational Advantages:

- Superior wear resistance reduces replacement frequency

- Consistent performance enables accurate project scheduling

- Cost-effective solution addresses budget constraints

- Proven reliability minimizes operational disruptions

- Sample testing programs support rapid adoption decisions.

Versatile Water Well Drilling Solution

Water well drilling teams require reliable, cost-effective drilling equipment that performs consistently across diverse geological conditions. The Versatile Water Well Drilling Solution combines proven technology with economic pricing to meet these operational requirements.

Design Optimization Features:

- Simplified cutter layout reduces manufacturing costs while maintaining effectiveness

- Durable construction materials ensure reliable performance in standard applications.

- Straightforward bit design minimizes complexity and potential failure points

- Compatible with standard drilling equipment and procedures

- Quality manufacturing standards ensure consistent performance.

This solution specifically addresses the needs of smaller drilling operations where price considerations significantly impact equipment selection decisions. Despite the cost-effective design, these bits incorporate essential performance features that ensure reliable operation and acceptable drilling rates.

The engineering approach focuses on maximizing value by incorporating proven design elements while eliminating unnecessary complexity. This strategy produces drilling equipment that meets operational requirements while remaining within budget constraints typical of water well drilling operations.

Economic Benefits:

- Competitive pricing supports project profitability

- Reliable performance reduces operational uncertainty.

- Standard specifications simplify procurement processes.

- Proven track record enables confident equipment selection

- Rapid availability supports urgent drilling requirements

Global Market Characteristics and Regional Considerations

North American Market Dynamics

The US drilling business puts a lot of emphasis on new technologies and running operations more efficiently, such as the High Performance 5 Cutter PDC Bit. Shale gas extraction companies need high-performance drilling systems that can handle difficult rocks while still being able to make money. American workers usually choose technology that has been tried and tested in the field and has a lot of data about how well it works.

Regulatory compliance is a big part of the process of choosing tools. Environmental concerns and safety rules affect drilling methods, causing a need for tools that have the least effect on the environment while also being the safest to use. Quality approvals and manufacturing norms are now necessary for tools to be approved.

European and UK Operational Environment

When drilling in the UK, especially with ocean sites, the tools used need to be very reliable, even when things go wrong. It is very strict about how technology works and how it's recorded because safety and saving the environment are very important to the law.

When someone buys something, they carefully look over the technical specs and quality standards. Engineers rate tools by looking at thorough information about how well they work, how well they were made, and how effective they think they will be in the long run. This way of careful review usually makes the buying process take longer, but it helps buyers build strong, long-lasting relationships with good sellers.

Middle Eastern Drilling Requirements

Firms that work with oil and gas often have to deal with rough terrain and weather when they are in the Middle East. Drilling tools need to be able to regularly cut through layers of hard rock, even when it's very hot outside.

Because of how important operating efficiency is in the area, there is a high demand for drilling solutions that increase entry rates while reducing problems downhole. Before a large-scale rollout, equipment selection methods usually include a lot of testing in the field to make sure it works well.

Central Asian and Australian Considerations

Cost-effective solutions that work reliably without being too complicated are often the most important thing in Central Asian markets. To mine in these areas, you need tools that can work in tough conditions and still make enough money to support large-scale activities.

Australia's drilling activities are used for a wide range of things, from mines to digging for water wells. The long lengths and rural sites of the operations make it even more important that the equipment be reliable and that the suppliers can help.

Strategic Procurement Recommendations

When evaluating drilling equipment options, technical engineers and purchasing managers should consider several critical factors that impact long-term operational success. Performance validation through sample testing provides essential data for informed decision-making, particularly when introducing new technology into existing operations.

Quality assurance becomes paramount when selecting drilling equipment. ISO 9001:2015 certification and comprehensive testing protocols indicate manufacturer commitment to consistent quality standards. Advanced testing equipment for performance verification ensures that each bit meets specified performance criteria before delivery.

Supplier capabilities significantly impact long-term partnership success. Manufacturers with dedicated research and development teams can provide custom bit design solutions that address specific operational challenges. Modern production facilities equipped with advanced processing equipment, including 5-axis machining centers and CNC machine tools, indicate manufacturing sophistication and quality control capabilities.

Technical support services enhance equipment value by providing operational guidance and troubleshooting assistance. Suppliers who offer integrated technical solutions demonstrate understanding of complete drilling systems rather than individual component focus.

The procurement process should include a thorough evaluation of manufacturer credentials, production capabilities, and quality control measures. Site visits to manufacturing facilities provide valuable insights into production processes and quality management systems.

Industry Trends and Future Developments

The drilling industry continues evolving toward more sophisticated solutions that address environmental concerns while improving operational efficiency. Advanced PDC cutter design, as exemplified by the High Performance 5 Cutter PDC Bit, incorporates computer modeling and simulation to optimize cutting structures for specific formation types. This technological advancement enables more precise matching of drill bit characteristics to geological conditions.

Manufacturing innovations focus on improving polycrystalline diamond compact bonding techniques and matrix material formulations. These developments extend bit life while maintaining cutting efficiency, providing enhanced value for drilling operations. The integration of downhole sensors and real-time monitoring systems creates opportunities for intelligent drilling equipment that adapts to changing conditions.

Conclusion

High Performance 5 Cutter PDC Bit technology represents a smart, future-ready choice for modern drilling operations facing harder formations, tighter budgets, and higher efficiency demands. By combining optimized cutter geometry, improved stability, and durable materials, these bits consistently deliver faster penetration rates, longer service life, and lower overall drilling costs. Across oil and gas, mining, and water well applications, their proven adaptability and reliability help operators reduce downtime and improve project predictability. As drilling environments grow more complex, advanced PDC solutions will continue to play a critical role in achieving safe, efficient, and economically sustainable drilling performance worldwide.

FAQ

1. What formations work best with 5-cutter PDC bits?

Five-cutter PDC configurations excel in medium- to hard-rock formations where balanced cutting action and stability become critical. These bits perform particularly well in shale formations, sandstone, and limestone applications where consistent penetration rates matter most. The design proves effective in both vertical and directional drilling operations.

2. How do these bits compare to conventional alternatives?

High-performance PDC bits typically deliver 15-30% faster penetration rates compared to traditional roller cone bits. The improved efficiency translates to reduced drilling time and lower operational costs. Additionally, PDC technology eliminates moving parts, reducing failure points and maintenance requirements.

3. What maintenance requirements should operators expect?

PDC drill bits require minimal maintenance compared to conventional alternatives. Regular inspection of cutters for wear patterns and damage provides insight into bit condition. Proper bit cleaning and storage between uses extends operational life. Most maintenance involves bit replacement rather than repair due to the integrated cutter design.

Partner with HNS for Superior Drilling Performance

Shaanxi Hainaisen Petroleum Technology delivers industry-leading High Performance 5 Cutter PDC Bit solutions backed by over a decade of manufacturing expertise and innovation. Our ISO 9001:2015 certified facility combines advanced 5-axis machining centers with rigorous quality control to ensure consistent performance across all drilling applications. As a trusted High Performance 5 Cutter PDC Bit manufacturer, we provide customized solutions for oil and gas exploration, mining operations, and water well drilling projects worldwide. Contact our technical team at hainaisen@hnsdrillbit.com to discuss your specific drilling requirements and discover how our proven technology can enhance your operational efficiency.

References

1. Smith, R.J. (2023). "Advanced PDC Cutter Technology in Modern Drilling Operations." Journal of Petroleum Technology and Engineering, 45(3), 178-192.

2. Wilson, M.K. & Thompson, A.L. (2022). "Performance Analysis of Five-Cutter PDC Bits in Unconventional Formations." International Drilling Technology Review, 38(7), 234-248.

3. Chen, L.W. (2023). "Quality Control Standards for Polycrystalline Diamond Compact Manufacturing." Industrial Diamond Applications Quarterly, 29(2), 67-81.

4. Rodriguez, P.M. (2022). "Economic Impact Assessment of Advanced Drill Bit Technology in Global Markets." Energy Economics and Technology Journal, 15(4), 445-462.

5. Anderson, K.R. & Davis, S.J. (2023). "Hydraulic Design Optimization in PDC Drill Bits for Enhanced Performance." Drilling Engineering International, 52(1), 89-104.

6. Taylor, N.H. (2023). "Regional Market Analysis for Advanced Drilling Equipment in Emerging Markets." Global Petroleum Equipment Review, 41(6), 312-327.