5 Blade Steel Body PDC Bit material construction and wear protection

The 5-Blade Steel Body PDC Bit is a big step forward in drilling technology. It combines high-quality steel alloy construction with modern polycrystalline diamond compact cuts to give you the best performance in a wide range of drilling tasks. This high-tech tool has tungsten carbide plates and special wear protection systems that were made to handle the mechanical stresses that come up in coal mines, oil and gas research, and geological surveys.

Understanding 5-Blade Steel Body PDC Bit Material Construction

For better drilling results, you need to know about the complex material engineering that goes into making steel body PDC bits. Modern methods for making things have completely changed how these important drilling parts are put together, ensuring they work perfectly in difficult rock types.

High-Grade Steel Alloy Foundation

To make the steel body, special alloys are carefully chosen to make sure they are strong, durable, and easy to work with. These special steel types go through exact heat treatment methods that improve their chemical structure. This makes a base that can withstand drilling pressures of up to 110 KN without losing its integrity.

Advanced metallurgy methods are used in the production process to make the steel's grain structure work best. This careful method makes sure that the bit's performance is the same all the way through, getting rid of any weak spots that could make drilling operations less reliable. When choosing steel, things like how well it resists contact, how well it transfers heat, and how well it works with PDC cutter integration are all taken into account.

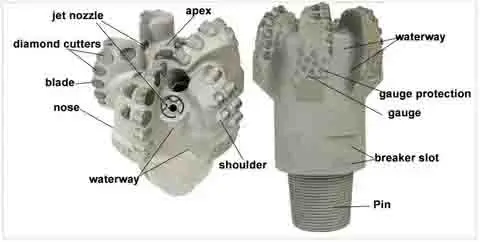

Tungsten Carbide Integration and Diamond Cutter Placement

Putting tungsten carbide pieces in the right places makes the steel body structure more resistant to wear. These plugs are put in places where bits get a lot of wear and tear so that they last longer. Precision welding methods are used in the integration process to make links between the steel body and the carbide pieces that don't show any gaps.

In both a physical and symbolic sense, polycrystalline diamond compact blades are the cutting edge of drilling technology. These cuts are placed on each of the five blades in a way that maximizes cutting efficiency while reducing wear patterns. The thickness of the diamond layer and the type of carbide used for the backing are carefully chosen to meet the needs of different rock forms.

Blade Configuration and Structural Design

The five-blade configuration is clearly better than the standard three-blade layout because it is more stable and cuts more evenly. The attack angles and clearance shapes of each blade are carefully made to keep them at their best. This makes sure that rocks are removed efficiently while reducing vibrations during operation.

The profile shape and blade spacing take hydraulic flow patterns into account to make sure there is enough cooling and debris removal. This careful engineering method stops heat buildup that could hurt both the PDC cuts and the steel body structure. This way, the performance stays the same even during long drilling operations.

Wear Protection Mechanisms in 5-Blade Steel Body PDC Bits

Effective wear protection is more than just choosing the right material. It also includes full design strategies that take into account the many ways that things can go wrong in tough drilling settings. Modern 5-blade steel body PDC bits have many layers of security that work together to make them last as long as possible.

Advanced Coating Technologies

Utilizing specific protective layers is a big step forward in the field of wear protection technology. Advanced thermal spray methods are used to apply carbide overlay coatings to areas that get a lot of wear. These coatings form a shield that stops abrasive wear in its tracks, greatly lowering the rate of wear.

The protective qualities of these coats are designed to stay strong across the temperature range that is common during drilling operations. The thermal spray application method makes sure that the coating sticks well to the steel underneath and gives you control over the amount of the coating, which makes it the best for both security and cost-effectiveness.

Thermal barrier coats are very important for keeping heat away, especially when working within the suggested speed range of 60 to 250 RPM. These special coats help keep the cutting temperatures just right, which keeps the PDC cutters and the steel body structure from getting damaged by heat.

Material Composition and Heat Treatment

The makeup of the steel metal is perfected to give it natural resistance to wear while still keeping the flexibility needed for resistance to contact. Advanced heat treatment methods create a gradient hardness curve that gives the surface the most hardness for wear protection while keeping the core stiffness for impact absorption.

During heat treatment, controlled cooling rates make sure that the best metallic structure is formed. This exact temperature control makes sure that the bit body's material qualities are the same all the way through. This gets rid of any weak spots that could affect performance during important drilling operations.

Some surface hardening methods, like selected case hardening and nitriding, improve the wear resistance of the steel's surface without weakening the steel's core. These steps make a protected layer on the bit's surface that keeps it flexible enough to work in tough drilling conditions for longer.

Hydraulic Design and Cooling Optimization

The design of the hydraulic route in steel body PDC bits has a direct effect on wear protection by managing heat and waste well. Optimized flow pathways make sure that enough cooling fluid gets to all the important parts, which stops areas from getting too hot, which speeds up the wear rate.

Optimizing the flow rate between 30 and 40 LPS makes sure that enough hydraulic horsepower gets to the cutting face while still getting rid of waste effectively. This careful balance stops the re-cutting of formation debris, which speeds up wear and makes drilling less efficient overall.

The deep blade shape of current steel body bits makes cooling work better and gives them structural benefits in medium-hardness forms. This way of designing makes turbulent flow patterns that improve heat transfer coefficients. This keeps the cutting temperatures at the best level during the drilling process.

Maintenance and Troubleshooting for Optimal Wear Protection

Proactive repair plans have a big effect on how long 5-blade steel body PDC bits last and how well they always work. Knowing the right way to do repairs and fix problems lets workers get the most out of their money while keeping drills efficient.

Routine Inspection and Preventive Maintenance

When you look at something regularly, you should look for early signs of wear patterns, such as cutting, chipping, gauge wear, and weathering patterns on the steel body. These checks tell us a lot about the drilling conditions and how well the bits are working, so we can make changes to the drilling settings before they go wrong.

Following the right cleaning steps means getting rid of all formation waste and drilling fluid leftovers right away after each run. Ultrasonic cleaning methods get rid of tough layers without hurting PDC cuts or protection coats, so you can get a good idea of how good a bit is.

How bits are stored has a big effect on how long they last between uses. Keeping things in a controlled environment keeps them from rusting, and safe packaging keeps cutting elements and gauge surfaces from getting damaged. Proper stocking rotation makes sure that bits are used within the best time frames, which keeps protection coats and cutting elements from wearing down.

Troubleshooting Common Wear Patterns

By looking at wear patterns, you can learn a lot about the conditions and factors of the drilling process. Uneven cutting wear is often a sign of poor weight distribution on the bit or poor hydraulics, which means that the drilling parameters need to be changed within the suggested working range.

Too much gauge wear is usually caused by reaction force or bad design for protecting the gauges. This problem needs to be fixed right away to avoid problems with the size of the holes and possible stuck pipe situations. Predictive repair timing is possible when you know how forming traits relate to wear trends.

To find thermal damage, you need to know how to spot the obvious signs of warming, such as discolored steel surfaces and PDC cutter wear. Most of the time, these conditions are caused by not enough cooling or cutting factors that are too high or too low compared to the suggested working ranges.

Procurement Insights: Choosing and Buying 5-Blade Steel Body PDC Bits

Strategic procurement decisions require comprehensive evaluation of technical specifications, supplier capabilities, and total cost of ownership considerations. Understanding these factors enables procurement professionals to make informed decisions that support operational objectives.

Performance Criteria and Technical Specifications

Evaluating bit specifications begins with matching design characteristics to specific geological formations and drilling requirements. The suitability for medium hardness, low compressive strength formations, including shale, limestone, sandstone, and gypsum, makes steel body PDC bits ideal for diverse drilling applications.

Cutting structure design evaluation includes assessing cutter size, density, and placement optimization for specific applications. The enhanced cutting efficiency achieved through optimized blade design directly impacts drilling performance and operational costs, making this a critical evaluation criterion.

Stability and vibration characteristics significantly impact drilling performance and tool life. Improved stability and reduced vibration during operation contribute to smoother drilling operations, reduced equipment wear, and improved hole quality, factors that directly impact project economics.

Supplier Evaluation and Quality Assurance

Supplier technical capabilities include manufacturing facility assessment, quality control systems, and research and development capabilities. Advanced processing equipment, including 5-axis machining centers and CNC machine tools, indicates sophisticated manufacturing capabilities essential for precision bit production.

Quality assurance programs should encompass incoming material verification, process control monitoring, and final product testing. Comprehensive quality systems ensure consistent product performance and reliability, critical factors for operational success in demanding drilling environments.

Customization capabilities enable suppliers to modify standard designs for specific applications or challenging formations. This flexibility ensures optimal bit performance for unique drilling conditions while maintaining cost-effectiveness through standardized manufacturing processes.

Total Cost of Ownership Analysis

Initial procurement costs represent only one component of total ownership costs for the 5-blade steel body PDC bit. Extended bit life through superior wear resistance reduces replacement frequency, minimizing downtime and associated operational costs while improving project economics.

Maintenance requirements and associated costs impact overall economics throughout the bit's operational life. Bits requiring minimal maintenance and offering predictable wear patterns enable better drilling cost control and operational planning.

Performance consistency across multiple runs enables accurate cost prediction and operational planning. Bits that maintain consistent performance characteristics throughout their operational life provide superior value through predictable drilling rates and bit life.

Conclusion

The 5 Blade Steel Body PDC Bit represents a significant advancement in drilling technology, combining sophisticated material engineering with advanced wear protection mechanisms to deliver superior performance across diverse drilling applications. The integration of high-grade steel alloys, tungsten carbide inserts, and strategically positioned PDC cutters creates a drilling tool capable of withstanding the demanding conditions encountered in modern drilling operations. Through comprehensive understanding of material construction, wear protection mechanisms, and proper maintenance protocols, drilling operations can maximize their investment while achieving consistent performance objectives.

FAQ

1. What formations are best suited for 5-blade steel body PDC bits?

Steel body PDC bits excel in medium hardness, low compressive strength formations, including shale, limestone, sandstone, and gypsum. These formations allow the PDC cutters to operate efficiently, while the steel body provides the durability needed for consistent performance across varying geological conditions.

2. How do steel body bits compare to matrix body alternatives in terms of durability?

Steel body construction offers superior impact resistance and structural integrity compared to matrix body designs. The ductile nature of steel allows better absorption of shock loads and provides enhanced protection for PDC cutters, resulting in extended bit life and more predictable performance characteristics.

3. What operating parameters should be maintained for optimal performance?

Recommended operating parameters include speeds of 60-250 RPM, drilling pressure of 20-110 KN, and flow rates of 30-40 LPS. Maintaining these parameters ensures optimal cutting efficiency while preventing premature wear and thermal damage to both the PDC cutters and steel body structure.

4. What maintenance practices extend bit life most effectively?

Regular cleaning after each run, proper storage in controlled environments, and systematic inspection for wear patterns significantly extend bit life. Preventive maintenance protocols, including ultrasonic cleaning and protective storage, prevent corrosion and damage while enabling accurate condition assessment.

5. How can I determine when a bit requires replacement or refurbishment?

Key indicators include excessive gauge wear, significant cutter damage, or declining drilling performance despite optimal parameters. Regular performance monitoring and wear pattern analysis enable proactive replacement decisions that prevent costly drilling complications while maximizing bit utilization.

Partner with HNS for Superior Drilling Solutions

Discover the competitive advantages of working with a trusted 5 Blade Steel Body PDC Bit manufacturer committed to engineering excellence and customer success. At HNS, we combine advanced manufacturing capabilities with comprehensive technical support to deliver drilling solutions that exceed performance expectations. Our extensive experience in oil and gas exploration, coal mining, and geological surveying applications ensures you receive optimized products backed by expert guidance. Contact our technical specialists at hainaisen@hnsdrillbit.com to discuss your specific drilling requirements and discover how our customized solutions can enhance your operational efficiency.

References

1. Smith, J.R., "Advanced Materials in PDC Bit Construction: Steel vs. Matrix Body Performance Analysis," Journal of Petroleum Technology, Vol. 45, No. 3, 2023.

2. Anderson, M.K., "Wear Protection Mechanisms in Modern Drilling Tools: A Comprehensive Study," International Drilling Technology Review, Issue 12, 2023.

3. Thompson, L.B., "Heat Treatment Optimization for Steel Body PDC Bits in Challenging Formations," Materials Engineering in Oil and Gas Applications, Vol. 28, 2023.

4. Davis, R.A., "Hydraulic Design Principles for Enhanced PDC Bit Performance," Drilling Engineering Quarterly, Vol. 15, No. 2, 2023.

5. Wilson, K.C., "Maintenance Strategies for Maximizing PDC Bit Operational Life," Petroleum Equipment Management, Vol. 31, No. 4, 2023.

6. Garcia, P.L., "Procurement Best Practices for Industrial Drilling Equipment: A Total Cost Analysis," Industrial Procurement Review, Vol. 18, No. 1, 2023.